Join us at Food Matters Live 2015

Join us at Food Matters Live 2015 to find out how OAL is working with The Knowledge Transfer Network (KTN) to bring best practice automotive manufacturing technologies to the food industry. The three day event running Tuesday 17 to Thursday 19 November at the Excel in London is the UK's first cross-sector event bringing together professionals from across the food and drink industry to address the most important challenges facing the food industry today including nutrition and population well-being.

Following two successful Innovate UK projects, OAL has been invited to speak on the KTN stand about both our Steam Infusion and cryogenic cooling projects. We will also be available to talk about our latest development APRIL (Automated Processing Robotic Ingredient Loading) following widespread anticipation for the launch of the new system early 2016. APRIL was recently covered in bakeryandsnacks.com.

Both KTN and OAL are members of Food Is Life, a consortium, which will also be at the event with the stunning BMW i8, seeking to bring disruptive change to the food industry. If you’re interested in joining, it would be great to meet up at the show, you can either catch us on the KTN stand or at the BMW i8 (which will be positioned near the VIP lounge).

The free to attend event attracts thousands of visitors every year from backgrounds such as R&D, food science, manufacturing and retailing so register here to come along and we may even let you take a seat in the car!

Transforming food processing at Gulfood Manufacturing, Dubai

We're speaking about disruptive change at the Next Generation Manufacturing Conference, part of Gulfood Manufacturing 2015 in Dubai on Tuesday 27 October at 15:30. We were approached by organisers following the launch of our revolutionary APRIL™ food processing system. APRIL uses principles from the automotive sector to link proven state-of-the-art cooking and materials handling technologies with automated robotic ingredient loading.

The talk will provide insights into how APRIL™ style systems will change both factory layouts and the flow of materials through a food processing facility. By removing the need for pipework, pumps and valves, APRIL will produce more consistent and better quality products, faster than current processes with significantly reduced ingredient wastage and energy costs, whilst taking up to 80% less factory space.

APRIL™ has been developed in partnership with a leading global robot manufacturer and the University of Lincoln, with a full-size demonstration due for installation December 2015 at the National Centre for Food Manufacturing. The development has come off the back of two £1 million Innovate UK funded government projects into improving the efficiency and quality of food products. APRIL™ will integrate and enhance two existing technologies being researched under the two Innovate UK collaborative research projects into cryogenic cooling and rapid heating and mixing (Steam Infusion).

The three day show is the region's biggest food and beverage processing industry event and brings together suppliers from over 60 countries, showcasing the very latest improvements in manufacturing. The show is a popular knowledge transfer and sourcing event which allows attendees to explore solutions for potential expansion on production capacity, creating greater efficiency and much more!

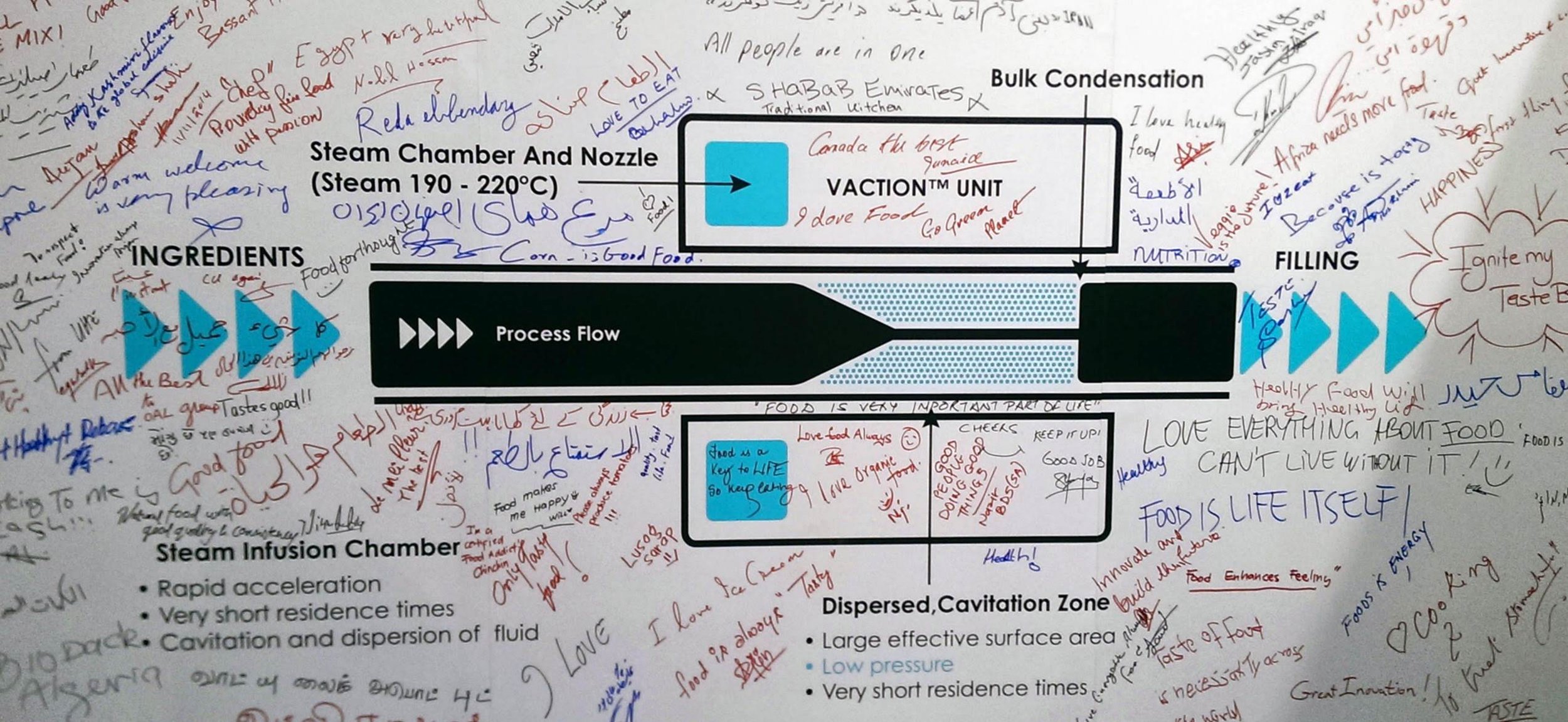

Food is Life at Gulfood Manufacturing "Food Wall"

At Gulfood Manufacturing, Dubai, the biggest food show in Africa and the Middle East, we decided to do something different to engage visitors. Steam Infusion is a revolutionary heating and mixing process, and from previous shows in the UK we recognised we need food manufacturers to think creatively and differently about their manufacturing processes. So to break down barriers and to get people thinking about what’s really important about food, we introduced them to our “food wall”. Visitors were simply asked to write what was most important about food to them on our “food wall”.

We were genuinely amazed by the excitement and engagement with the "food wall". Over the 3 days of the show, 473 people signed the wall from 70 different countries. Writing in Arabic, Chinese, English, Filipino, Hebrew, Japanese, Swahili, and Turkish to name a few. It really was a truly eclectic mix of global opinions on what’s important about food.

What we found?

Coming from the UK we were expecting people to write the commonly accepted important factors of food such as safety, quality, taste and flavour. These were key elements and many people from all over the world cited safety and taste as the most important areas to them.

But interestingly there was a real focus on the fundamental link between food and life. For instance “Food is life itself”, “Can’t live without food”, and “Africa needs more food.”

But should we have been surprised? Nestle, the biggest food manufacturer in the world, has the slogan “Good Food, Good Life,” clearly linking food to life itself and it’s true to say that without food we wouldn’t be here. But on a daily basis as engineers and food manufacturers do we make the connection between food and life in the UK?

But what’s the link with Steam Infusion?

Gulfood Food Wall Steam Infusion Unit

Often at exhibitions visitors have very specific requirements about what they are looking for and to a certain extent are closed down to things outside of their remit. By simply asking visitors to write what’s important about food on the wall, we found visitors opened up much more and were in a much better position to discuss innovation.

This innovation mind-set is really important to us because often with the Steam Infusion process we are radically changing traditional manufacturing processes, for instance going from a multi stage process to a single stage faster process. Likewise we found visitors engaged much more strongly with new product development and step changes to improving flavours and taste having written on the wall.

Hot application at Gulfood

Food is Life Gulfood Manufacturing Steam Infusion

Not only were people able to write on our walls but they could taste the difference as well. On the stand, we had pots of freshly made condensed milk made using Steam Infusion which attracted a lot of interest because of the considerable difference in product quality and operational performance. Steam Infusion condensed milk suffers no burn on discolouration, has a particularly smooth texture and cuts manufacturing times by 50%.

Super Steam Infusion Autumn: 9 innovation events, 6 awards

PPMA Innovation Award Steam Infusion

It’s been a busy September for the OAL team! Off the back of winning an award for Steam Infusion at the European Food Venture Forum in Denmark, we were at Leatherhead Food Innovation Day presenting Steam Infusion followed by the FDF Awards. With lots more events on the horizon, here are the highlights!

Steam Infusion won the most innovative food processing or packaging machine award at the PPMA Group Industry Awards 2014, held at the National Motorcycle Museum, Tuesday 30 September. In a very competitive category, Steam Infusion was recognised as the most innovative technology by the esteemed judging panel because of the health benefits the technology can bring to the food industry.

Steam Infusion EFVF2014AwardWinners

The European Food Venture Forum saw OAL pitching Steam Infusion's ability to create exciting new food products and ingredients to investors and manufacturers. The judging panel included senior executives from Anterra Capital, Arla Foods, BASF Venture Capital GMBH and Dupont Nutrition & Health all of whom assessed the technology on its business potential, technological merit, competitive position, and investment interest and team experience. Strong engagement from the judging panel and an award to go with it was a fantastic endorsement of the technology’s unique processing environment.

Leatherhead’s annual Food Innovation day seeks to showcase exciting technology developments within the food industry. Steam Infusion was well received by executives from 2 Sisters Food Group and Mondelez International particularly around the technologies ability to process heat sensitive food materials.

The very same evening saw the Food & Drinks Federation Awards, where Steam Infusion came runner up in the Innovation category.

Look out for us in the news as we have been shortlisted for more awards:

Ben Bowman

One of our talented engineers, Ben Bowman, is shortlisted for the young talent of the year category at the Food Manufacture Awards.

OAL has been shortlisted for company of the year and technological development at the Food Processing Awards 2014, please vote for us on their website.

Jake Norman, Sales & Marketing Manager, has been shortlisted for the 2 Degrees network Top 25 Under 25 year-olds in sustainability.

With a busy autumn ahead, you can meet the team at the following events:

OAL are sponsoring and will be attending Appetite For Engineering 2014, 21st October. We have a number of complimentary tickets available, please contact us if you are interested in attending, Tuesday 30th September to Thursday 2nd October.

Jake Norman (Sales & Marketing Manager) is speaking at Pack Expo in Chicago on the General Electric stand about Steam Infusion, sharing how we use GE connected insights for R&D into creating new and unique food products and ingredients.

OAL will be presenting at the prestigious Innovate UK Event 2014 “The Global Spotlight on UK Innovation”, 5th & 6th November, Old Billingsgate, London, find out more here.

The team will be at Gulfood Manufacturing, Dubai from 9th to 11th November presenting Steam Infusion, register here.

Winning at the European Food Venture Forum means the team progress to the final of the European Venture Contest in Dusseldorf, Germany, taking place 8-9th December 2014. Find out more here.