Disruptive food processing technologies

We recently had the opportunity to discuss how disruptive technologies will deliver a step change in performance for food manufacturing with the Daily Telegraph. With over 25 years’ experience in food processing, we understand the demands of 24/7 operation with tight deadlines and short shelf-life products and are in a unique position to work with the industry. Leading two collaborative research projects with prominent food manufacturers and research institutions, we now invest 8.2% of turnover in R&D.

As Harry says "It's not going to be easy, it's going to be a rollercoaster of change" but the opportunities are huge:

Like the automotive industry, over the next decade, food factories will change dramatically because of disruptive technologies with major implications for the whole supply chain. Food Manufacturing 4.0 has arrived. Highly flexible “lights out” manufacturing will enable the production of new products whilst intelligent product tracking will improve food safety and traceability. Smart factories connected to the industrial internet will react to changing consumers demand at an incredible pace.

That's why we are working as part of the Food Is Life consortium to deliver Food Manufacturing 4.0. The opportunities for embracing disruptive technologies are huge and we are constantly looking for new collaborations and partnerships to work towards this.

Get in touch with our experts to start your transformation today!

OAL dry materials handling featured on BBC!

A recent BBC series, "Inside the Factory: How Our Favourites Foods Are Made" focused on the way bread is manufactured. The programme spotlighted the Allied Bakeries West Bromwich site where OAL Group supplied a turnkey materials handling system for all dry ingredients used in the bread process.

BBCBreadFactory

Clips from the video can be found on the BBC.

Top safety accreditation for OAL

OAL has been awarded accreditation from Safecontractor for its commitment to achieving excellence in health and safety. Safecontractor is a leading third party accreditation scheme which recognises very high standards in health and safety management amongst UK contractors. Safecontractor is applicable to most sectors although it is particularly relevant to food manufacture, property, facilities management, retail and leisure sectors, all of which are big users of contracted services.

“Major organisations simply cannot afford to run the risk of employing contractors who are not able to prove that they have sound health and safety policies in place.

More companies need to understand the importance of adopting good risk management in the way that OAL has done. The firm’s high standard has set an example which hopefully will be followed by other companies within the sector.

Safecontractor plays a vital role in supporting our clients in meeting their compliance needs, whilst working with their contractors as they progress through the accreditation process.”

Under the Safecontractor scheme, businesses undergo a vetting process which examines health and safety procedures and their track record for safe practice. Those companies meeting the high standard are included on a database, which is accessible to registered users only via a website.

Client-organisations who sign up to the scheme can access the database, enabling them to vet potential contractors before they even set foot on site. These clients agree that, as users of the scheme, they will engage only those who have received accreditation.

Over 210 major, nation-wide businesses, from several key sectors, have signed up to use the scheme when selecting contractors for services such as building, cleaning, maintenance, refurbishment or electrical and mechanical work.

Safecontractor is a third party accreditation scheme that assesses health and safety arrangements. Many major clients recognise the scheme and accept the Safecontractor certificate as confirmation of competency.

Ready to work with a Safecontractor accredited supplier? Get in touch today!

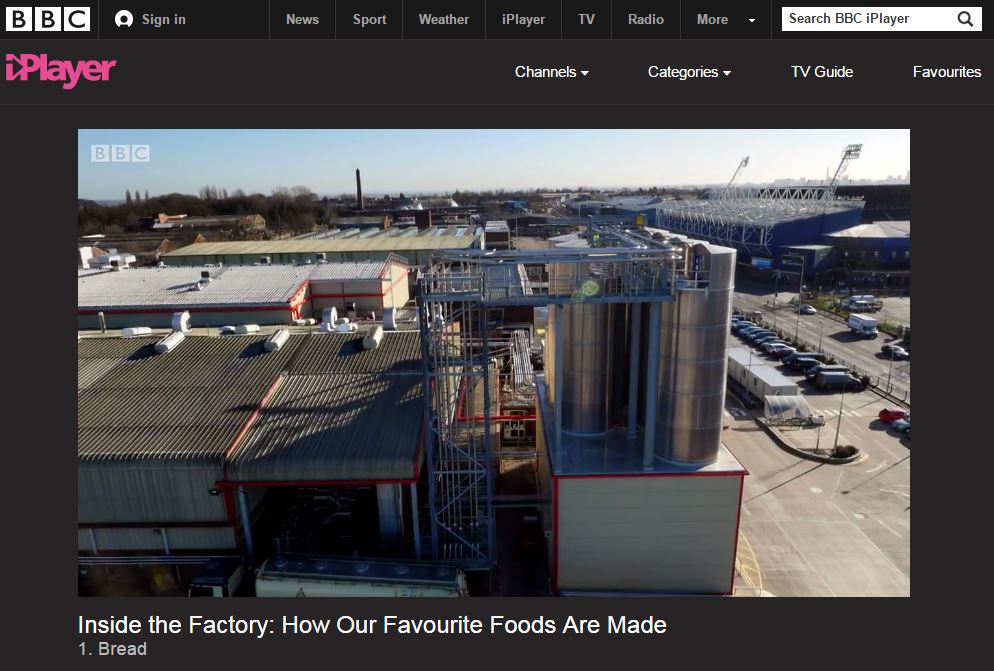

Food is Life at Gulfood Manufacturing "Food Wall"

At Gulfood Manufacturing, Dubai, the biggest food show in Africa and the Middle East, we decided to do something different to engage visitors. Steam Infusion is a revolutionary heating and mixing process, and from previous shows in the UK we recognised we need food manufacturers to think creatively and differently about their manufacturing processes. So to break down barriers and to get people thinking about what’s really important about food, we introduced them to our “food wall”. Visitors were simply asked to write what was most important about food to them on our “food wall”.

We were genuinely amazed by the excitement and engagement with the "food wall". Over the 3 days of the show, 473 people signed the wall from 70 different countries. Writing in Arabic, Chinese, English, Filipino, Hebrew, Japanese, Swahili, and Turkish to name a few. It really was a truly eclectic mix of global opinions on what’s important about food.

What we found?

Coming from the UK we were expecting people to write the commonly accepted important factors of food such as safety, quality, taste and flavour. These were key elements and many people from all over the world cited safety and taste as the most important areas to them.

But interestingly there was a real focus on the fundamental link between food and life. For instance “Food is life itself”, “Can’t live without food”, and “Africa needs more food.”

But should we have been surprised? Nestle, the biggest food manufacturer in the world, has the slogan “Good Food, Good Life,” clearly linking food to life itself and it’s true to say that without food we wouldn’t be here. But on a daily basis as engineers and food manufacturers do we make the connection between food and life in the UK?

But what’s the link with Steam Infusion?

Gulfood Food Wall Steam Infusion Unit

Often at exhibitions visitors have very specific requirements about what they are looking for and to a certain extent are closed down to things outside of their remit. By simply asking visitors to write what’s important about food on the wall, we found visitors opened up much more and were in a much better position to discuss innovation.

This innovation mind-set is really important to us because often with the Steam Infusion process we are radically changing traditional manufacturing processes, for instance going from a multi stage process to a single stage faster process. Likewise we found visitors engaged much more strongly with new product development and step changes to improving flavours and taste having written on the wall.

Hot application at Gulfood

Food is Life Gulfood Manufacturing Steam Infusion

Not only were people able to write on our walls but they could taste the difference as well. On the stand, we had pots of freshly made condensed milk made using Steam Infusion which attracted a lot of interest because of the considerable difference in product quality and operational performance. Steam Infusion condensed milk suffers no burn on discolouration, has a particularly smooth texture and cuts manufacturing times by 50%.

Super Steam Infusion Autumn: 9 innovation events, 6 awards

PPMA Innovation Award Steam Infusion

It’s been a busy September for the OAL team! Off the back of winning an award for Steam Infusion at the European Food Venture Forum in Denmark, we were at Leatherhead Food Innovation Day presenting Steam Infusion followed by the FDF Awards. With lots more events on the horizon, here are the highlights!

Steam Infusion won the most innovative food processing or packaging machine award at the PPMA Group Industry Awards 2014, held at the National Motorcycle Museum, Tuesday 30 September. In a very competitive category, Steam Infusion was recognised as the most innovative technology by the esteemed judging panel because of the health benefits the technology can bring to the food industry.

Steam Infusion EFVF2014AwardWinners

The European Food Venture Forum saw OAL pitching Steam Infusion's ability to create exciting new food products and ingredients to investors and manufacturers. The judging panel included senior executives from Anterra Capital, Arla Foods, BASF Venture Capital GMBH and Dupont Nutrition & Health all of whom assessed the technology on its business potential, technological merit, competitive position, and investment interest and team experience. Strong engagement from the judging panel and an award to go with it was a fantastic endorsement of the technology’s unique processing environment.

Leatherhead’s annual Food Innovation day seeks to showcase exciting technology developments within the food industry. Steam Infusion was well received by executives from 2 Sisters Food Group and Mondelez International particularly around the technologies ability to process heat sensitive food materials.

The very same evening saw the Food & Drinks Federation Awards, where Steam Infusion came runner up in the Innovation category.

Look out for us in the news as we have been shortlisted for more awards:

Ben Bowman

One of our talented engineers, Ben Bowman, is shortlisted for the young talent of the year category at the Food Manufacture Awards.

OAL has been shortlisted for company of the year and technological development at the Food Processing Awards 2014, please vote for us on their website.

Jake Norman, Sales & Marketing Manager, has been shortlisted for the 2 Degrees network Top 25 Under 25 year-olds in sustainability.

With a busy autumn ahead, you can meet the team at the following events:

OAL are sponsoring and will be attending Appetite For Engineering 2014, 21st October. We have a number of complimentary tickets available, please contact us if you are interested in attending, Tuesday 30th September to Thursday 2nd October.

Jake Norman (Sales & Marketing Manager) is speaking at Pack Expo in Chicago on the General Electric stand about Steam Infusion, sharing how we use GE connected insights for R&D into creating new and unique food products and ingredients.

OAL will be presenting at the prestigious Innovate UK Event 2014 “The Global Spotlight on UK Innovation”, 5th & 6th November, Old Billingsgate, London, find out more here.

The team will be at Gulfood Manufacturing, Dubai from 9th to 11th November presenting Steam Infusion, register here.

Winning at the European Food Venture Forum means the team progress to the final of the European Venture Contest in Dusseldorf, Germany, taking place 8-9th December 2014. Find out more here.

Olympus Automation now trading as OAL Group

Effective from Thursday 28th August 2014, Olympus Automation Ltd. will change its trading name to “OAL Group”.

This name change is in response to large international demand for our products and services and better reflects the company’s ability to provide solutions that involve all our engineering capabilities.

While our name is changing, our legal status, office address and telephone contact details will remain the same. The company’s business remains fundamentally unaffected by this change and all contracts with existing customers will remain unaltered, with corresponding obligations and rights assumed under the new trading name.

Moving forward, we look forward to providing the same services that Olympus Automation Ltd. has offered to clients to date and we ask all our stakeholders for their continued support.

From Thursday 28th August, our website will be switching to www.oalgroup.com and email address format to joe.bloggs@oalgroup.com

Steam Infusion shortlisted for FDF Innovation award

Steam Infusion from Olympus Automation (OAL) has been shortlisted for the Food and Drink Federation (FDF) Innovation Award based on its ability to deliver significant and innovative change to the food industry.

Steam Infusion is a revolutionary heating and mixing process that uniquely infuses steam into liquid food products in a vacuum. Early adopters of Steam Infusion include Greencore and Larco Foods who have generated significant business benefits from the technology. explains,

“Steam Infusion has allowed us to nearly double our previous throughput rates in sauce production. On top of this our meat sauce quality and consistency has improved dramatically.”

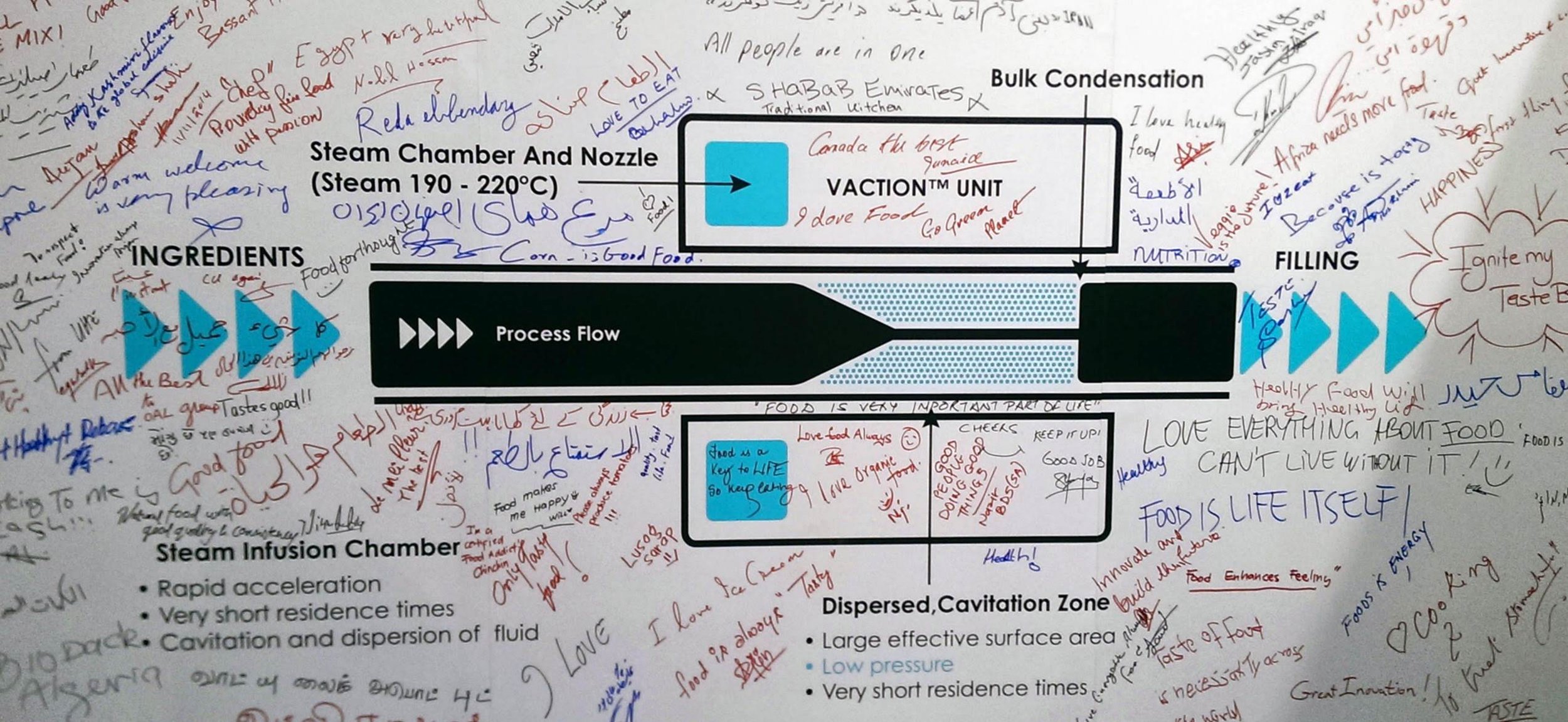

Further research and development is being undertaken in a £1 million UK government funded Nutrition for Life project at the Steam Infusion Test Centre in the National Centre for Food Manufacturing, Holbeach.

The unique Steam Infusion environment has been found to increase the flavour profile of food products in commercial trials indicating salt and other ingredients can be reduced without having a negative impact on flavour. The Nutrition for Life project seeks to provide the scientific understanding of the level and nature of the changes brought about by the steam infusion process and the nutritional advantage to be gained.

OAL will be presenting initial findings from the Nutrition for Life project at the PPMA show 2014 running from 30th September to 2nd October 2014. As well as the OAL team, academics from the University of Lincoln will be on the stand to answer questions on Steam Infusion and the project.

OAL team completes epic cycle ride

When OAL became the lead sponsors for ‘Coast to Coast in a Day 2014’ we didn’t anticipate the enthusiastic response from our employees and customers alike! The gruelling one-day event consists of riders enduring 150 miles of cycling through the mountainous Lake District, the Vale of York, and the Northern Valleys of the North York Moors, finishing in Whitby. Harry Norman, Managing Director at OAL, set the pace completing the ride in a time of 11 hours 49 minutes, with the full results available here. The team were raising money and awareness for the British Heart Foundation, while reflecting our commitment to sustainable solutions.

Inspiring sustainability

Harry has a passion for cycling, and felt the Coast to Coast event was a fantastic opportunity to showcase the sustainable elements of OAL. Harry commented;

“We like to get involved with events that clearly demonstrate how we do things differently as a company. The passion and dedication to complete the Coast to Coast event alongside the fact it is completed on bikes, aligns itself well with the company as we’ve made numerous strong commitments to sustainability. Furthermore, our Steam Infusion cooking technology has the potential to reduce salt from ready meals and many other products, and so it seems fitting raising money for the BHF, given the links of high salt content with heart disease.”

A picture paints a thousand words

See the gallery below for pictures of the guys reaching the top of Hardknott pass, Britain's toughest cycle climb with a height gain of 298m and 30% gradients!

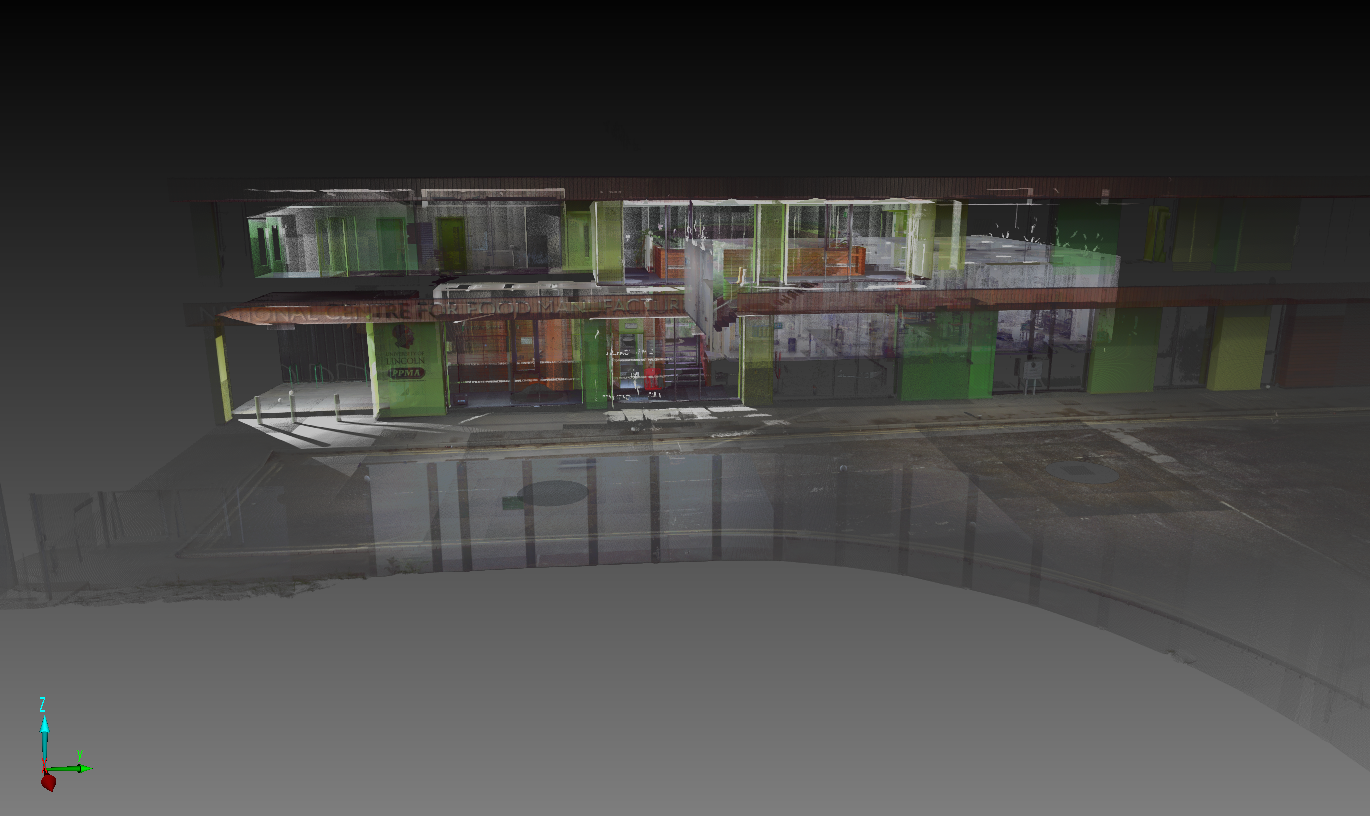

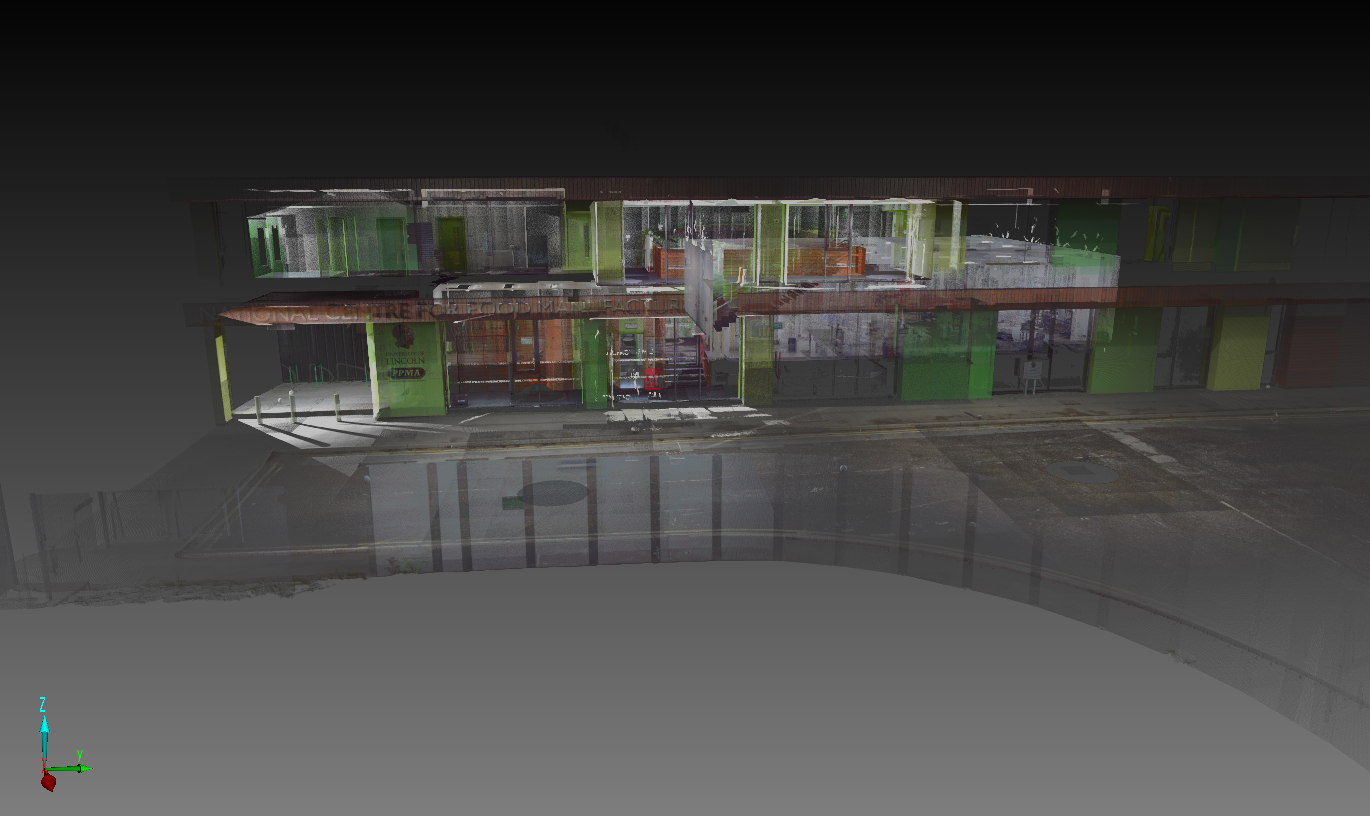

Successful 3D factory walk-through at the MTC

Olympus Automation successfully demonstrated a 3D food factory walk-through at the prestigious Manufacturing Technology Centre (MTC), Coventry. A point cloud scanned from the National Food Manufacturing Centre was imported into the cave, a virtual reality suite at the MTC, allowing users to literally walk around their factory, pictured above.

CAD objects generated in SolidWorks can be dropped into the factory, allowing customers to see how projects will look and work to a far greater detail than ever before. For instance a Steam Infusion System can be dropped into an existing food area so customers can see first hand how it fits and see the significant reduction in system footprint.

For Autocoding, panel placement can be simulated in the cave to optimise usability for shop floor workers, improving efficiency on the shop-floor.

With food manufacturers constantly striving to improve the ergonomic efficiency and health & safety of food areas, virtual reality factories present a great opportunity to accurately visualise and enhance designs and layouts of food factories prior to installation.

Driving exceptional efficiencies in the food industry

Olympus Automation has taken delivery of ten Volvo V40s, Five years into a strategy of running one of the most socially responsible green car fleets (25+) in the Food industry, With a large number of cars needing to be changed due to a combination of age and mileage, after extensive trials the Volvo V40 D2 (88g CO2) was chosen based on an estimated 30% improvement in real world economy and class leading CO2 emissions.

A key driving factor was the best in class safety for both Olympus Automation personnel and the wider community. The cars are all fitted with Volvo's award winning City Safety Technology and additionally the Blind Spot Information System, Lane Keeping Aid and Driver Alert Control.

The net result is an innovative fleet of exceptionally efficient and safe cars that perfectly complement our range of engineering solutions.

Harry Norman, CEO, explains "Company cars continue to be one of largest sources of carbon and improving it by up to 30% is great. Adding the optional safety features mean that we have done as much as we practically can to reduce the risk to our people and the wider community"

Olympus Automation dominates Food Processing Awards

Olympus Automation were nominated for 4 Awards at the 2013 Food Processing Awards and had success in all, including a WIN for our excellent Autocoding product. The dominance of the event was picked up by the after dinner comedian, Hardeep Singh Kohli, who continued to push the Olympus Automation name during his set. Everyone who attended certainly knew a lot more about Olympus Automation at the end of a very successful evening. Click here for the full Food Processing review of the awards ceremony.