Date Code Verification

Guarantee every product has the right date code and it’s legible.

Save time each changeover and prevent human input errors on printers by automating the setup and monitoring of your printers.

Ensure 100% date coding confidence by verifying the date code printed on every pack with APRIL Eye.

“Without a doubt I would recommend OAL to other manufacturers […] this system is the failsafe”

Are your printers set-up automatically?

The OAL system automatically sets up the printers to print the correct date code for the works order/job you’re running

Stop human errors. Operators no longer set up printers. The OAL system automatically sets up all printers (primary and secondary) to print the date code for the running job.

Brand agnostic. The OAL system works with all printer brands.

Fault and alarm detection. If the printer enters a fault state, the OAL system detects the errors, stops the line and forces a redownload of date code information.

Save time. Operators can be reassigned to other activities as they no longer set up printers.

“The team at OAL are easy to work with, working together we have implemented a robust automated label and date code verification system. The 24/7 support is quick, friendly, and efficient!”

How does APRIL Eye date code reading work?

Close the loop and verify the date code printed on the pack with the world's most powerful AI vision system. When would you need to read the printed date code:

Scenario 1, you have a fully automated secondary packaging with no human visual inspection. Generally, humans are good at spotting missing or blurred codes. If no people will see a pack before it hits the consumer’s hands, assessment is critical to ensure code quality.

Scenario 2, we use printers outside of automated control. Most companies utilise automatic printer control, but if a printer breaks, a printer outside of automated control could be used, exposing the business to the risk of human error.

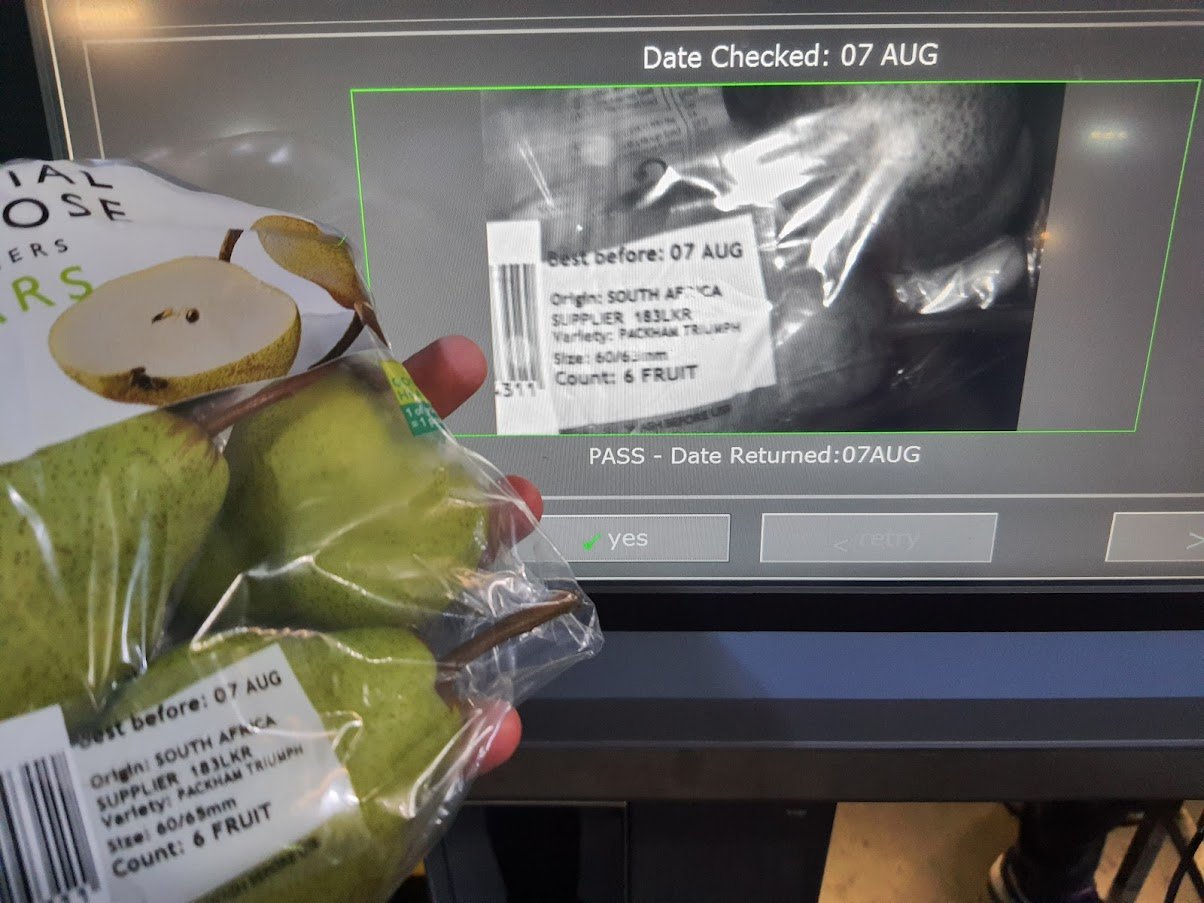

APRIL Eye (AE) Hand scanning

Take a picture of the date code using the hand scanner on the line terminal. The AE software will analyse the image, confirm the date code and verify against the running job. This check can be undertaken during job start-up checks and ongoing timed checks, effectively sampling print quality every 10 minutes.

APRIL Eye (AE) Inline verification

An additional camera is added to the packaging line to take a picture of every date code. The AE software will analyse the image, confirm the date code and verify against the running job. If an error is detected, a signal is sent to stop the line or a pack reject system.

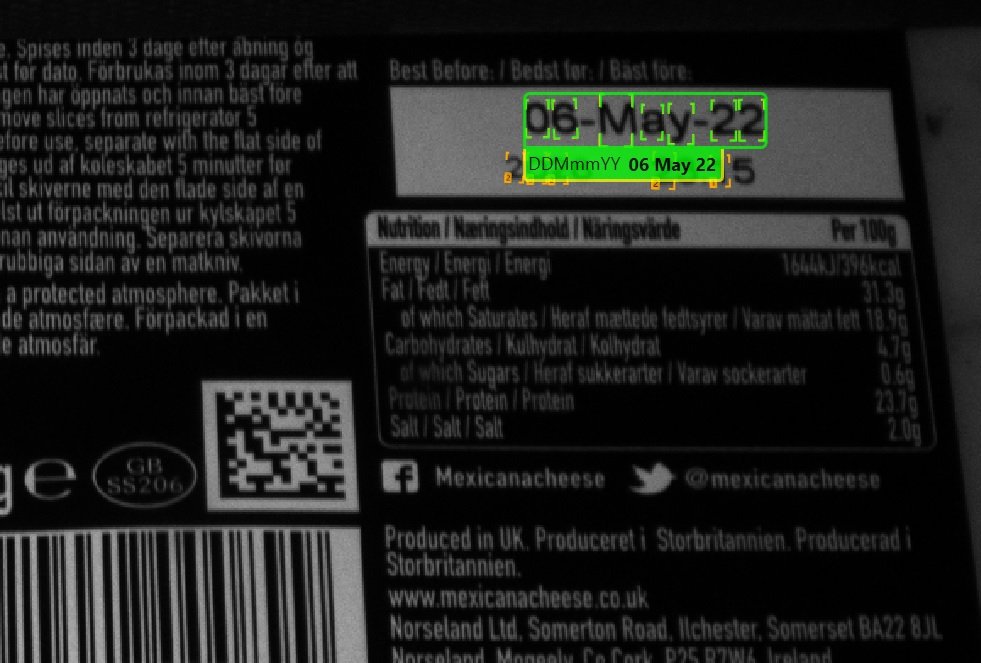

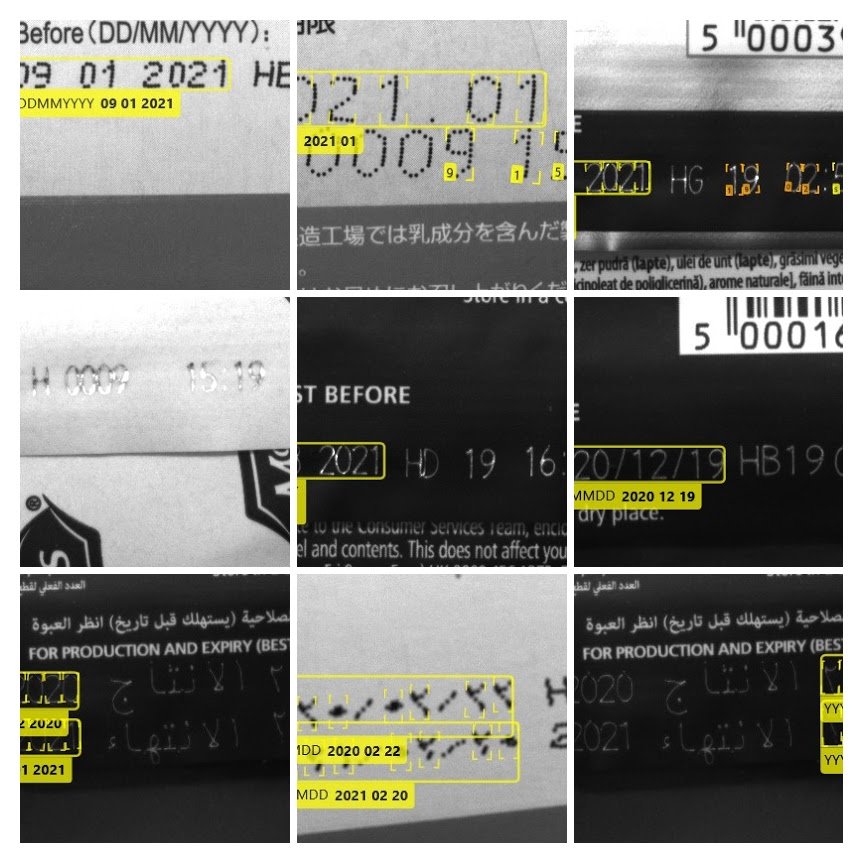

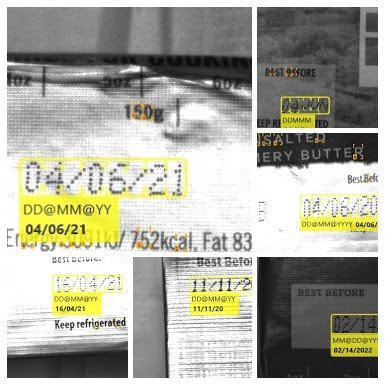

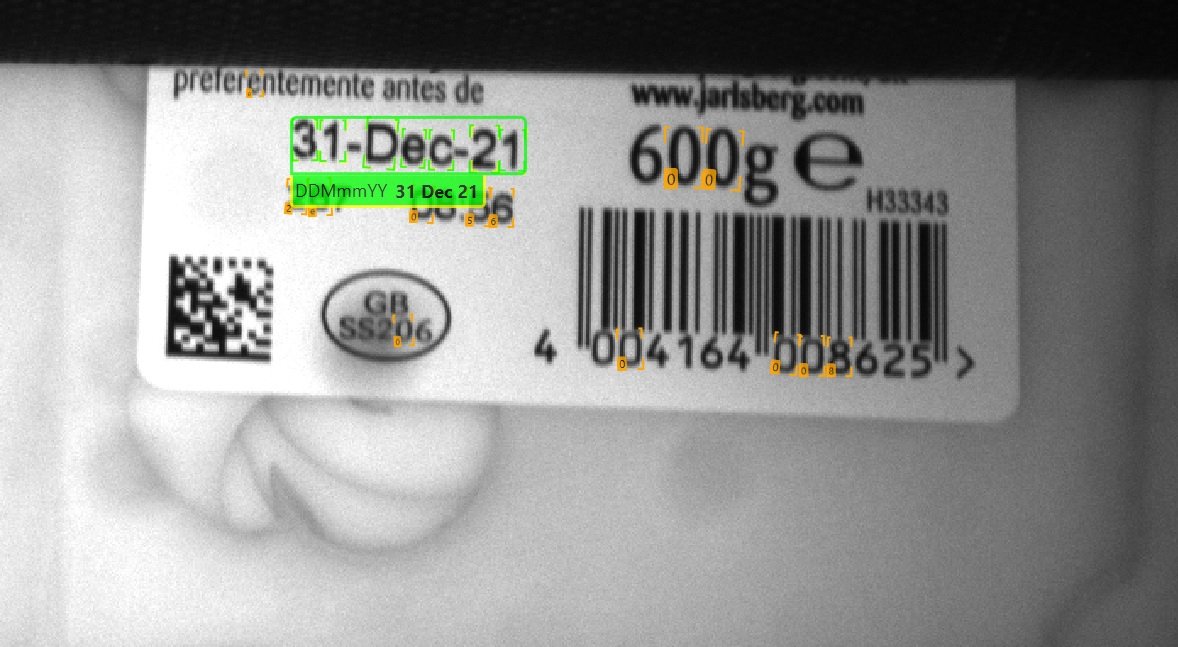

Why AI (artificial intelligence) not traditional vision (OCR)?

Traditional vision systems have relied on optical character recognition (OCR), designed to read specific characters. Due to the prevalence of inkjet printers in the food industry, which have a higher degree of variability, these vision systems have not been widely implemented as they have struggled with:

Varying fonts and sizes

Font distortion

Missing or incorrectly positioned text

Packing changes

Artificial intelligence allows us to overcome these issues by training the system to deal with lighting, positioning, and print quality variations. We've built robust data sets and models based on millions of images of date codes (different types, shapes, formats etc.), both thermal transfer and inkjet. These are deployed and configured for your specific application. Furthermore, there's no need for additional expensive vision cameras; all of the brains are in the software and not the hardware.

The History of APRIL Eye

OAL developed APRIL Eye in collaboration with the University of Lincoln in 2017 and launched in 2019.

You can read about it in the University of Lincoln impact report.

It was initially developed with Tesco in response to a requirement to ensure date codes were present on all their products.

Previously, operators were responsible for checking the date codes on printed packs.

APRIL Eye closes the automation loop by verifying every pack inline.

The system has since expanded to offer more product and pack checks.