The three key food processing trends from Interpack 2017

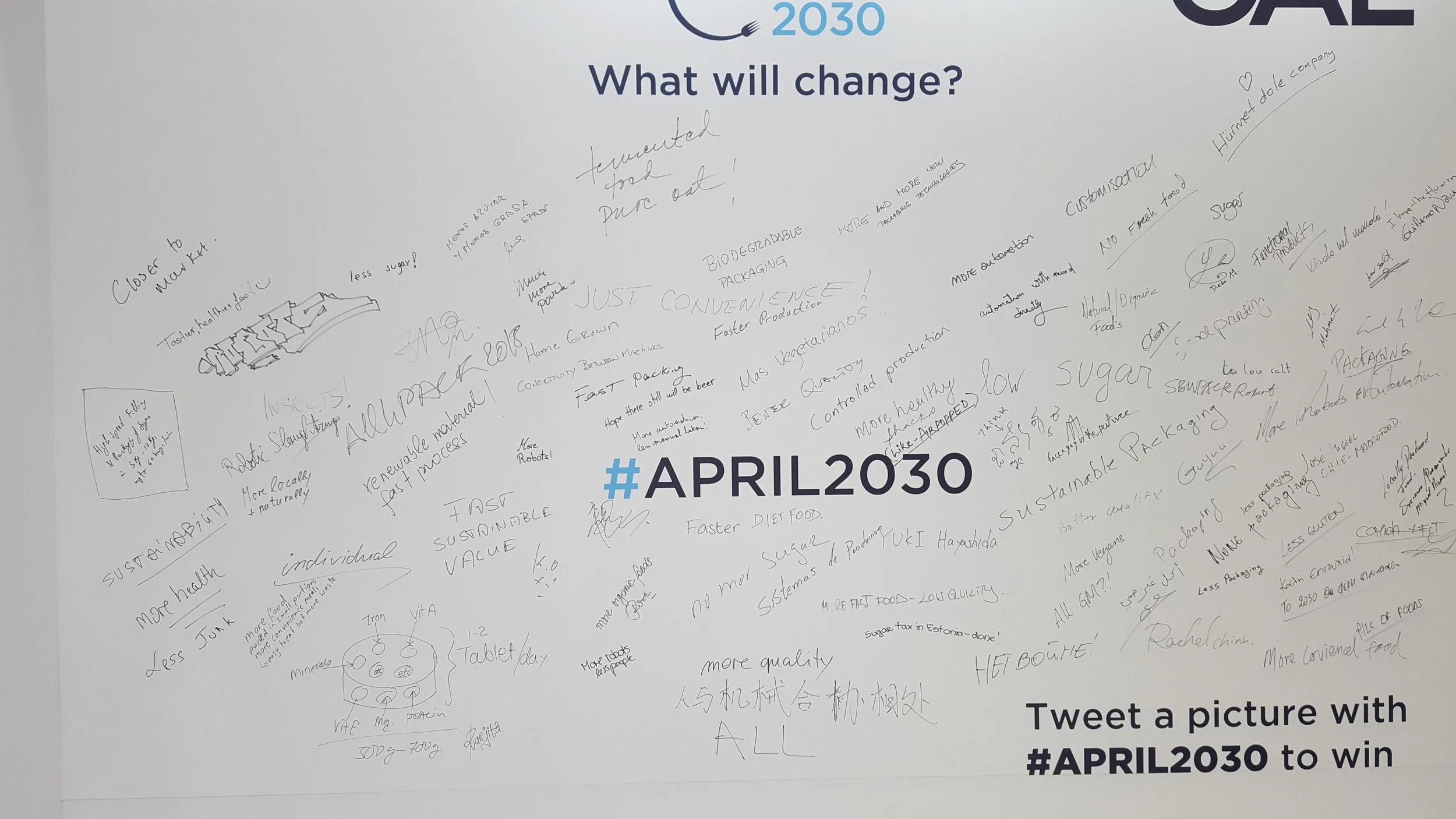

At Interpack 2017, the world’s largest process and packaging trade show, we asked the global community of food manufacturers to help us answer the question, what will change about food as we move forward to 2030? We tasked them with writing their solutions on our ‘food wall’, causing a great deal of excitement as visitors jostled to ensure their answer was more prominent than the last. Here, we sum up the top three trends they identified.

1) No sugar, low salt, less fat

Globally, food manufacturers are facing external pressures to investigate how they can improve the nutritional value of their products. Therefore, it is no surprise that when asked ‘ what will change about food as we move forward to 2030?’ comments such as ‘No sugar’ or ‘Less salt’ and ‘Low fat’ appeared. Many of our favourite products such as the KitKat have already adapted their recipes to meet government guidelines.

However, there is only so much you can reduce of an ingredient before hindering the taste of the product. So, what is the next step for manufacturers in this position? Click here to find out how changing the way you process ingredients can have a dramatic difference on your end product’s traffic light system without compromising on taste.

Interpack resuse recyle and consume with empathy

2) Sustainability

Sustainability continues to be on consumer's minds and is likely to become even more prominent as we move towards 2030. Interestingly, many of the comments related to reducing packaging or using more sustainable packaging, a challenge for the whole supply chain.

3) The rise of the robots

Thankfully, visitors to our stand agreed that the adoption of robotics and automation will continue to rise in food manufacturing. Visitors identified the ability of robots to automate both repetitive and more complex tasks in food factories.

On a final note...the death of the smartphone

A challenge for many...will anyone find a solution to eliminating the smartphone from mealtimes?

3 millennial innovations for Food Manufacturing 2030

We asked the latest cohort of Bakkavor Graduates "what will the food factory of the future look like?" The millennials were attending an innovation day at the National Centre for Food Manufacturing, as we supported the University of Lincoln inspiring future food industry leaders. “Millennials”, with a reputation for being digitally savvy, were shown the latest automation and robotics technologies before we discussed what will food manufacturing look like in 2030? There key ideas included:

1. Going digital on the shop floor

Unlike their baby boomer counterparts, millennials have grown up with digital technologies and are very much at one with their smart phone. One of the clear changes they see is the movement to digital manufacturing systems and the elimination of paperwork from the factory floor. The key drivers for the adoption of digital will be improved traceability, decision making and the overall equipment efficiency of a factory.

2. More robots

There are many repetitive manual tasks that will be automated as the cost of robotics and automation falls. From cakes to wraps, robots and collaborative robots will play a much greater role in our food production systems. A particularly interesting area of discussion was the potential impact of reduced human interventions on hygiene and the shelf life of products.

3. Flexibility is a requirement

But to do this, millennials recognised the need for flexibility within future food systems providing the opportunity for products, recipes and lines to be changed quicker and easier allowing flexible manufacturing and development.

Inspiring new technologies

At the National Centre for Food Manufacturing, OAL demonstrated how new technologies will shape food manufacturing. Demos included:

OAL Connected - Using automation to connect devices and remove paperwork from the factory floor. Tasks can be recorded digitally covering food safety, traceability, performance, productivity, recipe management, packaging and date security and ERP validation.

Steam Infusion - To demonstrate how new processing technologies can offer efficiency and product differentiation, the grads cooked up a broccoli and stilton soup with Steam Infusion. They could see first hand how the cooking process can eliminate burn on achieving a cleaner, more nutritional product with locked in flavours, colours and vitamins.

APRIL - APRIL (Automated Processing Robotic Ingredient Loading) our robotic chef is disrupting the way we handle and process raw ingredients by combining state of the art cooking and material handling technologies. The site of a five-tonne robot, cooking sauce, definitely inspired the graduates to the possibilities of robots in food manufacturing.

[mailmunch-form id="436502"]