Why Every F&B Manufacturer Needs Automated Packaging & Labelling Alongside Date Code Checks

As a responsible food and drink manufacturer, you understand the significance of delivering safe and trustworthy products to consumers worldwide. Customers trust your brand to give them safe, tasty products, and they want to know they can trust what's on the label. That’s why automated packaging and label verification alongside date code checks play a crucial role, serving as your dedicated quality control team to guarantee perfection.

As a responsible food and drink manufacturer, you understand the significance of delivering safe and trustworthy products to consumers. Customers trust your brand to give them safe, tasty products, and they want to know they can trust what's on the label. This is where automated packaging and label verification alongside date code checks play a crucial role, serving as your dedicated quality control team to guarantee perfection.

Why You Need Automated Packaging and Label Checks

When you're making hundreds, thousands, or even millions of items, it's hard to keep an eye on every single one. But your customers are counting on you to get it right. If a package goes out with the wrong label or missing information, it could be dangerous or even life-threatening to someone with allergies. Plus, if you're an own-label manufacturer, most retailers, including Marks and Spencer and Sainsbury’s, require a continuous online verification system.

With automated packaging and label verification system, you can check every single item you produce to make sure it's packaged and labelled correctly.

How OAL automated packaging and label verification works: We install cameras on your production line that scan every package. They check it against the job you're running and if something's not right, they'll stop the line so you can fix it. It's like having a second pair of eyes that never get tired or distracted.

The system stops the line and alarms if there is a fail-safe fault including:

Wrong packaging detected

Excessive no reads, product detected but no barcode found

Sensor failure

It's not just about safety and law either. If your products always look perfect and professional, it's good for your business. People are more likely to trust and buy from a brand that looks like they've got their act together.

Watch how the automated label verification works:

Why You Need Date Code Verification

Accurate date codes are equally crucial. They inform retailers and customers about the product's manufacturing and expiry dates, preventing early spoilage or unnecessary discarding of perfectly good stock. Incorrect date codes can tarnish your reputation and adversely affect your bottom line.

The good news is OAL has a system for this too. Our system configures your printers to ensure the accurate printing of date codes for each job, eliminating human errors like typos or incorrect printer settings.

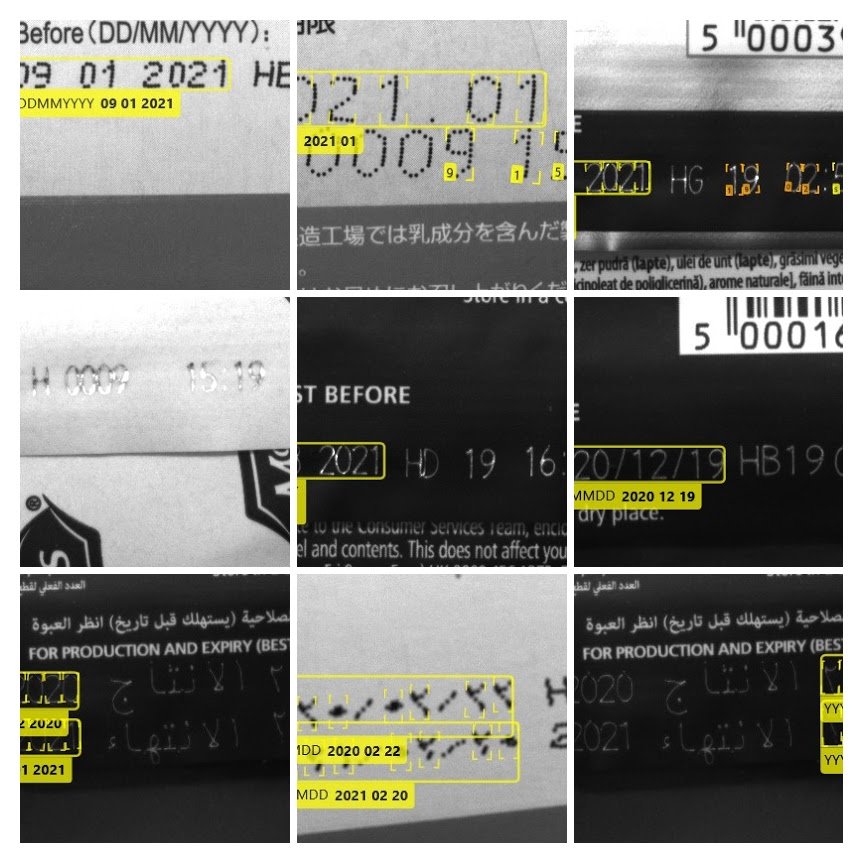

Our AI vision system, known as APRIL Eye, meticulously inspects every date code to ensure correctness and legibility. It adapts effortlessly to different fonts, sizes, and positions, showcasing its exceptional versatility.

Wrapping It Up

So, why do you need automated label and packaging verifications alongside date code checks? It's simple: to make sure your customers can trust your products, to follow the law, and to keep your products looking their best. It's all about taking pride in what you do and making sure you're delivering the best for your customers.

At the end of the day, OAL's systems are there to help you do just that. Need help? Let’s have a chat.

5 Compelling Reasons to Prioritise Pre-Weigh Automation in Your Next Personal Care Digitalisation Initiative

Industry 4.0's wave is reshaping the personal care sector, merging the digital and physical worlds to create smart factories. However, this digitalisation journey often neglects a crucial stage - pre-weigh operations, which remain labour-intensive and unchanged. As part of the industry's nascent digitisation, it's crucial to prioritise pre-weigh operations automation, providing a springboard towards operational excellence.

Industry 4.0 is opening up fresh and exciting opportunities in the personal care sector, making operations more streamlined and efficient. It's bringing our digital and physical worlds closer together, paving the way for smart factories as the next big thing in manufacturing. The first significant move? Upgrading an often-ignored area: pre-weigh operations.

Pre-weigh operations currently feel a bit old-fashioned, still heavily reliant on human work and untouched by the digital age. Typically there are over 400,000 powder additions by hand per year. This stands in stark contrast to the advanced automated packaging lines we use today. But this manual step in the process is ripe for digital transformation. A standard APRIL™ Robotics Weighing System can automatically dose 500,000 powder additions per year. Here are five compelling reasons to automate the pre-weigh process:

A pre-weigh area before and after robotic automation

Health & Safety is Paramount

Regular exposure to powders, dust, and potentially carcinogenic ingredients present significant health and safety risks to operators. Automating pre-weigh operations can vastly reduce these hazards. The APRIL™ Robotics System ensures precise dose of every powder, reducing chances of operator error, injuries, and fatigue. A safe, efficient workspace improves not only staff wellbeing but also the performance of the company.

Boost Efficiency

Many personal care companies embrace “lean manufacturing”. Pre-weigh is the first step in the manufacturing process. Downstream constraints in either mixing or packing are elevated ensuring they are always served right-first-time raw materials, eliminating downtime.

Better Yield and Precision

Automating pre-weigh processes can lead to significant improvements. Having an accurate recipe from the start makes the process reliable and efficient, reduces waste, and maximises return on investment. The APRIL™ Robotics Weighing System uses proven weighing algorithms to accurately dose and handle even the trickiest ‘non-free flowing’ raw materials, down to +/- 1 gram.

Assured Quality and Traceability

Modern consumers want to be confident in what they're buying. With the APRIL™ Robotics' automated weighing and powder dosing systems, personal care manufacturers can ensure each powder is dosed correctly the first time. This eliminates human error, provides traceability, and helps earn consumer trust.

Bonus: Embracing the Power of AI and Just-In-Time Manufacturing

AI-based scheduling can make operations more dependable and adaptive, which are vital features of just-in-time manufacturing. The APRIL™ Robotics System can directly receive orders from your ERP, automate over 500,000 manual powder additions per year, and even offer protection of IP by removing the need for operators to know the constituents of any formulation, thereby securing your "secret sauce".

Conclusion

In a nutshell, in the fast-moving world of personal care manufacturing, digitalisation is key. To remain competitive, pre-weigh automation must be embraced, paving the way towards improved safety, reliability, and profitability. The vision is clear: integrating automated pre-weighing into your digitalisation strategy is the catalyst towards leaner, safer, and more productive operations.

With APRIL™ Robotics, we can not only revolutionise pre-weigh operations, but also speed up full-scale factory digitalisation.

Simply put, digital adoption is less a choice than a competitive imperative. APRIL™ Robotics stands ready to guide you through smart factory transformation, stepping confidently towards Industry 5.0.

Protecting Workers' Health: The Call for Powder Handling Automation in Food Manufacturing

The food industry is constantly evolving, and companies that recognise the importance of worker safety and well-being are leading the way. However, protecting workers from the risks of powder exposure has always been a challenging task. Often, traditional solutions to these risks are not practical or cost-effective. Fortunately, with the advent of robotics and automation, a solution is now available.

Urgency to Embrace Powder Handling Automation

The food industry is constantly evolving, and companies that recognise the importance of worker safety and well-being are leading the way. However, protecting workers from the risks of powder exposure has always been a challenging task. Often, traditional solutions to these risks are not practical or cost-effective. Fortunately, with the advent of robotics and automation, a solution is now available.

Manual powder handling processes such as scooping, pouring, and weighing have been an integral part of the industry for decades. However, these processes put workers at risk of respiratory problems, lung damage, and cancer caused by exposure to hazardous powders. By investing in powder handling automation, companies can reduce the risk of exposure and ensure that their workers can work in a safe and healthy environment.

Beyond Respiratory Health: The Overlooked Impact of Dust Exposure in Food Manufacturing

The F&B manufacturing industry faces significant challenges when it comes to health and safety. According to HSE, respiratory diseases account for 12.5% of all occupational disease cases in the industry, with 12,000 new cases reported annually. In the food industry, occupational asthma accounts for 33% of compensation cases, with bakers being the second most affected group as reported by the Department of Work and Pensions Industrial Injuries Scheme. Dust from grain, flour, bakery dust, egg protein, fish protein, etc., are the primary culprits. These hazards can cause eye irritation, skin irritation, allergies, and other respiratory issues.

These symptoms can significantly impact a worker's quality of life and, in some cases, can even lead to long-term health problems.

Full automation is the solution. Automated systems, like those offered by OAL, significantly reduce workers' exposure to dust and other harmful particles, providing a safer and healthier workplace.

A Smart Investment: How Powder Handling Automation Can Boost Worker Health and Manufacturing Processes

Investing in powder handling automation not only protects workers' health but also brings several other benefits for both worker safety and manufacturing processes. Below are some of the key benefits of powder handling automation:

Benefits for Worker Health and Safety:

Reduced dust exposure - Automated powder handling systems eliminate the need for manual processes such as scooping, pouring, and weighing, significantly reducing workers' exposure to dust and other harmful particles that can put their health at risk.

Improved air quality - Advanced filtering systems in automated powder handling systems capture and eliminate any dust generated during the handling process, improving air quality, and reducing the risk of respiratory problems.

Safer workplace - With over 1,700 acute injuries reported every year, powder handling automation is a game-changer. By eliminating the risk of accidents and injuries associated with manual powder handling processes, automated systems provide a safer workplace, preventing back injuries and other occupational hazards.

Benefits for Manufacturers:

Increased efficiency - Automated systems ensure that the correct amount of powder is dispensed every time, eliminating the risk of over or under dosing, which can lead to product quality issues. Automated systems also have a higher throughput capacity, reducing production time and increasing efficiency.

Reduced waste - Automated powder handling systems accurately dispense the correct amount of powder, reducing waste and improving overall product quality.

Improved product quality and IP protection - Automated systems guarantee precise and consistent dosing, resulting in high-quality products that meet desired specifications and food compliance standards. By limiting access to the system, automation can also prevent unauthorised changes to the recipe, reducing the risk of errors and cross-contamination. This, in turn, enhances intellectual property (IP) protection by providing a reliable and traceable record of production.

Investing in powder handling automation is not only a smart business decision but also the best thing to ensure better efficiency and safety in operations. Protecting worker health and safety is a top priority for all organisations, and automated powder handling systems provide an effective solution for reducing dust exposure and improving overall workplace safety. The improved product quality provided by powder handling automation can also have a significant positive impact on a company's bottom line.

OAL's Innovative Solution for Doughnut Bakery: Protecting Workers' Health and Elevating Product Quality

Automated powder handling systems are a smart business investment. OAL's innovative solution for a doughnut bakery demonstrates how powder handling automation can significantly enhance worker health and safety while improving product quality. The system, which features three big bag stations with sifting, eliminates the incorrect batching of ingredients and minimises the loss of ingredients during transfer.

Image on left: The new silo designed and installed by OAL at the bakery

Image on right: Three Big Bag stations with Sifting

While small recipe additions are still made manually, the system's advanced features, such as an HMI and recipe management system, simplify monitoring of the production line and automate ingredient additions. This reduces the need for manual labour and minimises worker exposure to harmful particles.

Furthermore, commissioning and certification ensure that the system operates as required, and post-installation support is provided to ensure a smooth and efficient production process. The solution has enabled the doughnut production line to store and transport dry and liquid-based ingredients more efficiently, providing a safer and healthier working environment for bakery workers while ensuring high-quality products for consumers.

Explore the full case study here.

By embracing automation with APRIL, manufacturers can improve product quality and efficiency while addressing health and safety concerns for operators. With robots performing heavy lifting, musculoskeletal disorders can be avoided, and operators can be trained for more value-added roles such as controlling robots or maintaining equipment. The challenge will be to ensure that our workforce has the right skills to meet this future vision.

Building A Better World with Industry 5.0

Industry 5.0, the era of ‘Human-Tech Collaboration,’ merges the latest technological advances with human expertise to achieve the best of both worlds. By combining Industry 4.0's technological innovations with value-driven, human-centric initiatives, Industry 5.0 facilitates a seamless and collaborative interplay between people and machines, resulting in a high capacity, more sustainable, safe, and human-centric approach to food and beverage manufacturing.

The new industrial revolution will focus on celebrating workers and making technology work for them, not the other way around.

Discover more about how Industry 4.0 and 5.0 are transforming the future of food and beverage manufacturing and learn about the megatrends driving the shift towards the factory of the future in our exclusive report here.

The Responsibility of the Food Industry: Prioritising Workers' Health through Powder Handling Automation

The industrial revolution is entering a new era with Industry 5.0, where human and technology collaborate for a safer, sustainable, and equitable workplace. The food and beverage manufacturing industry is stepping up to this challenge by adopting robotics and automation for hazardous manual tasks like powder handling, weighing, and ingredient dosing. By embracing full automation, the industry not only reduces workers' exposure to harmful particles and dust but also improves efficiency, reduces waste, and enhances product quality. It is time for the industry to prioritise worker safety and take proactive measures towards Industry 5.0 for a better future.

The Future of Food Safety: How Robotic Automation is Taking on Food Contamination

The use of robotics and automation is gaining immense popularity in the food and beverage industry, with the potential to revolutionise how food is produced, processed, and delivered. Automation systems are playing a pivotal role in reducing the risk of contamination by minimising human intervention and improving product traceability.

The world is currently locked in a perpetual battle with food safety issues, as contamination incidents and food scandals consistently endanger public health and shake consumer confidence. Unsafe food costs low- and middle-income countries a staggering US$ 110 billion annually in productivity and medical expenses. Food safety is a critical concern for consumers, especially those with food allergies. It is imperative that manufacturers ensure that the right ingredients in the right quantities are used in their products. Incorrect or undeclared ingredients can have serious health consequences, as seen in recent incidents such as Pret's undeclared sesame allergy. Such recent high-profile food contamination incidents across the world serve as a reminder of the need for innovative solutions to preserve food integrity and security.

Fortunately, there is a revolutionary solution to combat food contamination and improve food safety standards through the use of robotics and automation. While traditional methods have been utilised to mitigate the issue, the use of robotic automation presents a transformative solution.

This article explores how robotics and automation are helping to combat food contamination, and the benefits they provide to manufacturers and consumers alike.

The Crucial Importance of Food Safety and Integrity

The World Economic Forum has emphasised the immense impact of food safety on public health, economic growth, and social stability. As such, food safety and integrity are integral components of the food and beverage industry, influencing both consumer confidence and public health. The achievement of ambitious standards of food safety and integrity requires a comprehensive approach that covers all aspects of the food supply chain, from farm to table. This approach includes the implementation of effective hygiene practices, the enforcement of stringent quality control measures, and ensuring traceability and transparency in the production and distribution of food products. Prioritising food safety and integrity not only safeguards consumers but also improves brand reputation, resulting in a more sustainable and responsible food system.

The Food Contamination Challenge

Food contamination is a persistent challenge facing the food and beverage industry worldwide, as demonstrated by recent product recalls. In 2020, food manufacturers in the UK experienced multiple recalls due to poor food quality, undeclared allergens, and other forms of contamination. These recalls underscore the critical need to maintain high standards of food safety and integrity in the industry. Similarly, in the United States, Tyson Foods, Nestle USA Inc., and other manufacturers also faced product recalls, resulting in substantial financial penalties and significant harm to their reputations.

These recalls serve as a reminder of the critical need to maintain high standards of food safety and integrity in the industry. They underscore the importance of implementing robust measures to prevent food contamination through proper ingredient mixing and usage in manufacturing process and ensure product traceability. Food manufacturers have a responsibility to ensure that their products are safe and free from harmful contaminants. Neglecting this responsibility may result in legal and financial consequences, as well as damage to their brand reputation and loss of consumer trust. Ultimately, the failure to protect consumers from food contamination could have serious health consequences, making it crucial for food manufacturers to prioritise food safety and integrity.

Embracing Robotic Automation as a Solution

The use of robotics and automation is gaining immense popularity in the food and beverage industry, with the potential to revolutionise how food is produced, processed, and delivered. Automation systems are playing a pivotal role in reducing the risk of contamination by minimising human intervention and improving product traceability. Robots are now extensively used for sorting, grading, and packing tasks, resulting in improved efficiency and reduced risk of cross-contamination. Additionally, automated systems can detect any defects or contaminants in food products before they reach consumers, ensuring that only high-quality products are delivered to the market.

One area where robotic automation solutions - like APRIL Robotics - have proven particularly useful is in the handling of raw materials and ingredients. This is a critical component of food safety, and our technology has demonstrated how robotic automation can significantly improve the accuracy, efficiency, and quality of ingredient handling across the supply chain. Our APRIL Robotics Weighing System has been utilised by Agrana Fruit, leading to a step-change in safety, quality, accuracy of weighing, and efficiency.

By automating the previously manual process, Agrana Fruit achieved improved product safety and consistency while reducing the risk of contamination. Automated systems ensure that raw materials are safely stored and handled, minimising the risk of contamination, and can help to ensure that ingredients are accurately weighed and mixed, reducing the risk of errors and inconsistencies in the final product. Furthermore, robotics and automation can aid in reducing waste and improving sustainability by optimising production processes and minimising energy and water usage.

Boosting Traceability and Hygiene: The Benefits of Robotic Automation in the Food Industry

The Implementation of Robotic automation in the F&B industry offers numerous benefits:

Enhanced Precision and Traceability: Precision and accuracy are critical in the production of food products, and automation can help manufacturers achieve this. Automation allows manufacturers to create consistency in their products, reduce the risk of contamination, and increase production efficiency. This process can be carried out using advanced software and sensors to control the manufacturing process and ensure that the correct ingredients are used. Robotic automation also offers accurate and consistent weighing and handling of ingredients, significantly reducing the risk of contamination. Additionally, automation technology provides real-time monitoring of ingredient sources, enhancing food traceability. OAL's APRIL Robotics Weighing System allows manufacturers to perform weighing and handling tasks more accurately, efficiently, and faster than human operators, with zero errors or waste. This increases productivity, reduces costs, and makes the business more competitive.

Improved Hygiene and Contamination Prevention: The daily exposure to powder and dust represents a significant health and safety risk. To mitigate the risk associated with manual handling, the removal of humans from the task is crucial. Robotics and automation offer a reliable solution, as they operate in highly regulated environments, minimising cross-contamination risks, and ensuring food processing facilities comply with rigorous hygiene standards.

Optimised Production and Waste Reduction: Robotic automation streamlines repetitive tasks, expedites production time, and minimises waste, resulting in lower production costs and improved product quality. Automated systems can also optimise production processes, reducing energy and water usage and minimising the environmental impact of food production.

Restored Consumer Confidence: Recent food scandals have weakened consumer trust in the food industry. Robotics and automation can boost food safety, decrease contamination risks, and restore consumer confidence. By automating previously manual weighing operations, the risk of human error is reduced, resulting in consumers feeling more confident in the products they purchase.

OAL's Robotic Automation: Revolutionising Food Safety Measures

The global challenges of food contamination and integrity still persist, posing a serious threat to public health and consumer confidence. Adopting robotic automation is the solution to this pressing issue, as it can enhance precision, traceability, and hygiene, while fortifying the food supply chain.

As the global population grows, there is an increasing demand for efficient, sustainable, and safer food production. To meet this demand, the food and beverage manufacturing industry is embracing innovative technologies like robotics, automation, and AI. By combining these advances with value-driven, human-centric initiatives, the Industry 5.0 era has begun, facilitating a seamless and collaborative interplay between people and machines. This approach leads to a high-capacity, sustainable, safe, and human-centric approach to food and beverage manufacturing. Check out our special trends report to learn about the latest megatrends in the food and beverage manufacturing industry.

As the world faces ongoing food safety challenges, adopting advanced technology is crucial to ensure a safer and more sustainable food system for future generations. At OAL, we are committed to this mission, tirelessly working to improve the way food is made and make it safer for consumption both today and in the future.

Auger vs. Robotic Powder Dosing: Exploring the Future of Powder Handling Technology

Precise dosing and handling of powders is critical in ensuring product quality and consistency in batch manufacturing. Auger-based powder dosing has been the go to technology for many years but robotic powder dosing is revolutionising how powders are dosed and handled. Here we will compare these two technologies, examining their advantages and limitations, to help you decide when choosing the right powder dosing solution for your application.

Precise dosing and handling of powders is critical in ensuring product quality and consistency in batch manufacturing. Auger-based powder dosing has been the go to technology for many years but robotic powder dosing is revolutionising how powders are dosed and handled. Here we will compare these two technologies, examining their advantages and limitations, to help you make an informed decision when choosing the right powder dosing solution for your application.

Auger Powder Dosing: The Traditional Choice

Auger-based powder dosing systems have long been the go-to solution for handling powders. They utilise a rotating auger screw housed within a tube or trough to transport and dispense powders at a controlled rate. The auger system has several key advantages:

Simplicity: Auger dosing systems have relatively simple mechanical designs, which make them easy to maintain and operate.

Adaptability: Auger systems can be easily integrated with other equipment, such as mixers, hoppers, and conveyors, making them a versatile option for a variety of applications.

However, auger systems also have their limitations:

Typical 10 bin auger system with storage limitations

Limited accuracy: Auger dosing systems can be less accurate than robotic dosing systems, especially when handling powders with varying particle sizes and densities.

Clogging and contamination risks: The mechanical nature of auger systems can lead to clogging, requiring frequent cleaning and maintenance. The same design also raises concerns about cross-contamination when handling different powders.

Limited dosing range due to turndown ratio: Auger dosing systems often have a limited dosing range due to their turndown ratio, which is the ratio of the maximum to minimum flow rates that the system can handle. This limitation can make it challenging to accurately dose smaller powders or adapt to varying production needs. In contrast, robotic dosing systems can offer greater flexibility and precision across a wider range of dosing requirements.

Robotic Powder Dosing: The Future of Powder Handling?

Robotic powder dosing systems are a more recent innovation, using advanced robotics and automation to handle powders with precision and accuracy. These systems offer several key advantages over auger dosing:

High accuracy and repeatability: Robotic dosing systems can achieve extremely accurate dosing, with minimal variation between doses. This is particularly important for applications requiring precise and consistent powder dosing.

Flexibility and expansion: Robotic dosing systems can easily adapt to different powders and dosing requirements, making them highly versatile and suitable for a wide range of applications. Storage can easily be expanded by adding additional storage containers to the system

Reduced contamination risks: Robotic dosing systems are designed to minimize contact between the powder and the dosing equipment, reducing the risk of contamination and clogging.

However, robotic systems also have some drawbacks:

Higher upfront cost: The advanced technology and engineering of robotic powder dosing systems mean they have a higher initial investment than auger systems.

Complexity: Robotic dosing systems may require more specialised knowledge and skills to operate and maintain, potentially increasing training and ongoing maintenance costs.

Conclusion: What's right for your application?

Both auger-based and robotic powder dosing systems have unique advantages and limitations, each suited to different applications and requirements. Auger systems are a cost-effective and simple solution for many powder handling needs, while robotic systems offer high accuracy, flexibility, and reduced contamination risks.

When deciding which system to choose, it is essential to consider your specific application requirements, such as the level of accuracy needed, the variety of powders being handled, and the overall budget. By carefully weighing the pros and cons of each technology, you can select the powder dosing solution that will best meet your needs and help ensure the highest quality and consistency in your products.

The Three Critical Ingredients for Automation Success in the Fresh Produce Industry

With 30 years of experience helping food companies automate, we have identified three key ingredients for success: starting with the end in mind, building internal capability with time to play and test technology, and choosing a software platform over a product.

In the ever-evolving world of fresh produce, it's crucial for businesses to stay ahead of the curve by embracing new technologies and automation. At OAL, we specialise in helping fresh produce businesses automate their packhouses to ensure right-first-time, efficient production. From correct labelling, date and country of origin coding to real-time production data, we help keep your business in sync.

With 30 years of experience helping food companies automate, we have identified three key ingredients for success: starting with the end in mind, building internal capability with time to play and test technology, and choosing a software platform over a product.

#1 Start with the End in Mind

Drawing inspiration from Stephen Covey, it's essential to have a clear vision of the final outcome in any automation project. By defining objectives such as productivity, changeover and downtime reduction, and what sets you apart, you can focus your automation efforts on supporting your overall business goals. For instance, if longer term you want to drive your packhouse from data in your ERP, it’s important to factor this in from the outset. Starting with the end in mind ensures a more focused and successful automation plan.

#2 Build Internal Capability with Time to Play and Test Technology

Begin your automation journey by engaging team members and key stakeholders right from the start. Their valuable production knowledge and insights will be instrumental in crafting a more efficient and effective automation strategy. Take a methodical approach by testing technology and different methods on a single production line first, allowing for "low-cost" mistakes to be made. These proof of concept trials will ultimately lead to a faster and smoother roll-out of new technologies across your entire business with demonstrated paybacks and benefits. By fostering collaboration and leveraging stakeholder expertise, you'll set the stage for a successful automation project.

#3 Choose a Software Platform Over a Product

Building applications on an established platform like the Ignition SCADA platform, rather than from scratch, provides:

Greater scalability: A platform approach allows you to scale your automation projects more effectively as your business grows. cohesive platform integrates better with existing systems, offering a unified data management solution that promotes better decision-making and efficiency.

Adaptability: As the fresh produce industry evolves, a software platform enables you to adapt more quickly to changes in technology, regulations, and market demands.

Cyber security: Entrusting critical cybersecurity and IT management tasks to a platform owner with a large, dedicated team offers significant advantages compared to relying on limited resources within a small organization. The cybersecurity teams at industry giants like Microsoft and AWS are equipped with extensive expertise and resources, which can provide superior protection and support when compared to a smaller, bespoke software business.

Conclusion

Automation success in the fresh produce industry depends on a clear vision of the desired outcome, building internal capability, and selecting a robust software platform. By focusing on these three critical ingredients, fresh produce businesses can overcome complexity, ensure right-first-time production, and stay ahead in the competitive market.

Ready to transform your fresh produce business with automation? Learn from our experiences with Wealmoor and Berry Gardens - download our comprehensive brochure now and explore the essential ingredients for automation success!

The Future of Powder Handling Health & Safety: Robotics Takes the Lead

If you’re in the bakery business, you’ll already be familiar with the many health & safety considerations that must be monitored and mitigated. There are the usual ones that come with any industrial facility, but there are a whole host of those specific to the powders and dust and how to protect your operators, without a simple and cost-effective solution. But that’s where robotics comes in.

Health and safety are always top priorities in manufacturing, but when it comes to handling powders and dust, the risks can be particularly challenging to manage. Operators must contend with the potential health risks associated with powders and dust, and finding simple and cost-effective solutions to mitigate these risks can be a major challenge.

Fortunately, robotics is emerging as a game-changer in powder handling safety. By automating the handling of powders and dust, robotics can help protect operators from exposure to hazardous materials and improve overall safety in the workplace. With robotics, manufacturers can reduce the risks associated with powder handling, while also improving efficiency and productivity.

The perils of powders

Powder ingredients can be difficult for operators to work with safely. Any fine powder in any industry, will create dust that could have a negative impact on operator health as the actions taken with the powders, from sieving and weighing to conveying and blending, all generate dust as the product is moved from one place to another.

Flour dust in particular is labelled a hazardous substance as defined by the Control of Substances Hazardous to Health (COSHH) Regulations 2002, because repeated and long-term exposure can cause occupational asthma and respiratory irritation, such as rhinitis, as well as skin conditions like dermatitis. There are many steps that must be taken to reduce the amount of dust people breathe in to the lowest level reasonably practicable, but the measures are not always correctly interpreted as we saw from the £159,000 fine handed to a bakery in 2018 that failed to protect its staff.

The risk of working around these powders in bakeries is stark. While the overall incidence rate of occupational asthma has decreased since 1999, the rate of new cases amongst bakers as reported by occupational physicians is now the highest of any occupation in any industry, according to the Health & Safety Executive (HSE) in the UK. So what are the measures that bakeries can take to protect operators, and are they sufficient?

Rising regulation

The HSE in the UK requires manufacturers to avoid exposing their employees to dust, or where not practical, to adequately control exposure. The Workplace Exposure Limit (WEL) of flour dust is 10mg/m3 (averaged over 8 hours) for long-term exposure and 30mg/m3 (averaged over 15 minutes) for short-term exposure. Yet the HSE believes that 2mg/m3 dust in the air for staff working in the weighing and handling of powder ingredients is possible to achieve. How, you may wonder?

HSE advises manufacturers to keep ingredient handling to a small, dedicated area with good airflow, only accessible to trained staff who open all containers carefully and scoop gently. It’s recommended that companies implement local exhaust ventilation (LEV) systems at the source of the dust, using short extraction ducts and disposing of the air in a safe place away from windows, doors and air inlets. Manufacturers should also conduct regular maintenance as well as implement alarms for blockages or failures in the extraction system. The facility should try to only use low-dust additives and single dose packets to avoid the need for weighing, as well as supplying the appropriate PPE to its workforce, or even RPE (respiratory protective equipment) in some cases, and ongoing health surveillance for your employees… The list goes on, as do the costs. The bakery that was fined in 2018 spent £232,000 on solutions to ensure compliance and protect its staff - a hefty sum that reveals the potential costs involved in the implementing the current measures.

No one would deny that these are all vital aspects of bakeries’ duty of care to its staff – no one’s health should be in danger in the workplace. Yet it doesn’t seem right that even with all of these measures, there’s still an incidence rate of 38.8 per 100,000 (not accounting for under-reporting) for bakers and confectioners who have been exposed to flour dust during the course of their work.

According to the Federation of Bakers’ publication, A Baker’s Dozen, if there is a solution out there that can help to reduce risk, it should be implemented, as can be seen on page 9:

“To comply with the regulations exposure levels should be kept not only below the WELs, but are reduced as low as reasonably practicable. In practice this means that if there is a technically achievable and cost‐effective control that reduces exposure, it must be put in place.”

Robotics to the rescue

We all know that the best way to reduce risk is to ensure that staff are not put into situations where they will encounter a hazard. That’s why the latest solution, the APRIL Robotics Ingredient Handling system is the new solution the industry has been waiting for. By using robotics to carry out the manual weighing and ingredient handling tasks, bakeries can transform their operations, achieving unmanned ingredient weighing and taking their operators away from the risk, moving into the ‘Elimination’ section of the above hierarchy of control.

With an APRIL Robotics Ingredient Handling system, the task is fully automated, also helping to mitigate the problems of social distancing that are now part of our daily life. Using robotics and advanced automation, bakers can achieve unrivalled accuracy, efficiency and allergen control. The system allows you to weigh out ingredients to an accuracy of +/- 1g every time, improving consistency of batches while reducing waste. Combining exceptional storage density with an unparalleled turndown ratio for high accuracy ingredient scaling, a robot retrieves and manages your ingredients from a network of APRIL smart containers (ASCs) as per your recipe and scales them into an ASC Blend Container. The ASCs are managed through the system, including cleaning operations, offering a reliable and repeatable unmanned operation.

Furthermore, with APRIL Robotics there is a reduced chance of cross-contamination due the dedicated ingredient containers and contact components within the APRIL Robotics Ingredient Handling system. This also offers full traceability for the product, ensuring that products are labelled accurately to reflect the contents of the product on the packaging and helping to prevent product recalls as well as protecting consumer safety.

In this way, bakeries can not only protect their operators, but also boost productivity, increase accuracy, reduce the risk of cross-contamination and safeguard consumer health.

Remove operators from risky operations with APRIL Robotics while also boosting your bottom line.

How much does a label and date code verification system cost?

We take you through the factors that affect the price of a label and date code verification system. Every business has its own requirements, so a single price can’t cover every packaging line scenario but by the end of this article you will have a solid understanding of the factors that drive cost.

One of the first questions many food manufacturers ask when automating their packaging lines is how much does label and date code verification (Autocoding) cost?

This is a great question, but, unfortunately, there is no black and white answer.

In this article, we will take you through the factors that affect the price of a label and date code verification system. Every business has its own requirements, so a single price can’t cover every packaging line scenario but by the end of this article you will have a solid understanding of the factors that drive cost.

Once we’ve covered standard functionality, we’ll review additional “added value” options.

“Standard functionality” is subjective. Our definition ensures compliance with all current retailer codes of practice but these requirements are constantly evolving. A current requirement in demand is date code verification, the ability to read the date code printed on the pack. As food manufacturers move towards unmanned packaging lines, advanced vision for online date code verification is becoming increasingly prevalent and will likely become “standard” over the next couple of years.

How much does Autocoding cost?

A standard label and date code verification system (Autocoding) can cost anywhere from £10,000 up to £40,000+ per packaging line.

Now, you’re probably asking yourself, “Why is there a big difference in price per line” Here’s why...

A standard label and date code verification system is made up of:

Hardware: Line terminals (IPCs, HMIs, PLCs), 1D/2D barcode scanners, vision cameras, sensors, brackets and accessories.

Labour: Installation, commissioning, software integration and training.

Software: The system software is typically modular and supplied on a one-off perpetual licence. Some vendors may offer software as a service (SAAS).

The complexity of a solution will dictate whether your system is leaning towards the low/high side of the cost spectrum. The key drivers of complexity are:

Packaging complexity. The number of packaging elements and SKUs.

System functionality: Packaging verification. Date code control. Vision. OEE. Paperless, to name a few.

System integration: A stand-alone system is the most cost-effective option however there are big benefits to integrating with existing business systems like your ERP, MES or other systems.

Standard functionality

What is the standard functionality for a label and date code verification system?

One of the main reasons for buying a label and date code verification system is compliance with a retailer’s code of practice.

Tesco, ASDA, Sainsbury, Waitrose, M&S, Morrisons, Lidl, Aldi, Co-op, Amazon all have slightly different technical requirements.

For the purpose of comparison, our definition of standard functionality ensures compliance with all codes of practice (but please get in touch with us if you need specific advice).

We’ve broken down the costs as follows alongside the requirements to satisfy retailer’s codes of practice:

Line terminals

Packaging verification – 1D/2D barcode scanners

Printer control

Software

Database manager

Line terminal

Reporting

Training and audits

Line terminals and HMIs

Example of a line terminal

Each packaging line will require a line terminal for the operator to select jobs and complete quality checks. The line terminal requires a hand scanner for completing checks and a login method e.g. RFID or ID card scan.

The line terminal can be wall-mounted or on a stainless-steel pedestal and requires a power and ethernet connection. The line terminal is normally located where operators currently conduct their paper-based checks.

Typically, each packaging line will have its own dedicated line terminal, but some may have a 2nd line terminal or use a mobile device for quality checks if there is a high-low care divide.

For compliance, the system must be suitable for use in a food packaging environment and the line terminal should be a minimum of IP65 with a colour touchscreen interface.

Hardware costs have been subject to fluctuation due to supply chain issues and double-digit percentage increases have been common. Provided good access, a single line terminal should be installed within half a day. For a budget cost, we would advise £9,000 per line terminal, installed and commissioned.

Packaging verification - 1D/2D barcode scanners

The system must automatically monitor all packaging throughout the production run to ensure the product is always packed in the correct packaging.

Systems will use inline barcode scanners to scan the barcodes on the packaging and verify it’s correct. The number of scanners required per line depends on:

The number of packaging elements. For instance, one scanner to read the lid and one to read the base label.

Artwork position of barcodes. The same packaging may have the barcode in a different position for different customers. Additional scanners may be required to “see” the barcode.

A quick google search reveals the cost of barcode scanners can vary from £800 to £7,000+ per scanner based on the functionality and capabilities they offer. To meet code of practice requirements and to minimise downtime, a high-performance scanner is required:

The system must show the number of ‘Good reads’, ‘No Reads’ and ‘Mismatches’ detected. The system should ensure no ‘Misreads’ or ‘Mismatches’ and be guaranteed for a Six Sigma Accuracy (99.99966%) level i.e. 3.4 defects per million opportunities (DPMO).

The scanner should also be capable of reading both conventional 1D linear barcodes (e.g. EAN13/8) as well as 2D Data matrix barcodes.

See: 1D and 2D barcodes - what’s the difference?

Aside from the hardware cost of a scanner, time is required for an engineer to install and commission each scanner. Again, the amount of time required is subject to a number of factors (access to the packaging line, mounting arrangement) but per scanner, engineering time will typically start from 4 hours. For a budget cost, we would advise £3,000 per scanner, installed and commissioned.

Printer control and monitoring

Printer control requires the system to automatically set up all online date coding or label printing devices from the database date code information.

Each printer manufacturer will charge a one-off licence fee to connect to each printer. Time is required for the commissioning of each printer. For a budget, we would advise £3,000 per printer, installed and commissioned.

The label and date code verification system will integrate with the printer company label creation software:

Domino printers will use QuickDesign.

ICE/Videojet/Linx printers will use Clarisoft

Markem printers will use COLOS.

Printer control removes the risk of operator error from entering the wrong date code for the printer to print but doesn’t guarantee the date code actually printed on the pack. Some printers now offer the ability to check the print ribbon to validate the print is applied. To fully close the loop, a picture can be taken of the printed date code on the pack and validated with vision/AI to check the printed date code is correct on the pack. See advanced vision below.

Software

The system software comprises:

Database manager. Software to view and manage the master product database. The database is installed on an existing SQL server managed by the manufacturer.

Line terminal. Software to run jobs and complete quality checks on the packaging line.

Reporting. Software to report on jobs, quality checks and traceability.

Typically, the software is modular and sold on a one-off perpetual licence as part of a turn-key solution. The software will require configuration, installation, commissioning and testing by trained engineers. The amount of engineering time will depend on the total number of devices and configurations required for each packaging line.

To ensure code of practice compliance the software must:

Have a central auditable database of packaging components and date coding rules for every product SKU, which resides on a central server in the system.

Create a central electronic audit log for all factory line events. The audit log must not be compromised by network or central server failure.

Manage system access with authorisation level based on user role. Hence, the requirement to login to the line terminal with RFID or a swipe card.

The system must have the ability to manage production exception conditions such as process or equipment concessions in an auditable way.

The system must have the ability to deploy the product data from the central database to a factory-based line terminal in such a way that the integrity and use of the system is not compromised by either network or central computer failure.

The system must be resilient against accidental or deliberate human error or tampering. Examples of the types of events that must be protected against include:

Disabling of packaging barcode scanning devices by unplugging, covering or misdirecting

Disabling of product detection PECs by unplugging, covering or misdirecting

Disconnection of the communication links between the system and date coders or labellers

Over-riding code set-up information from the system by direct entry/modification of the deployed date code at the coder screen

Training and audits

Users of the label and date code verification system will require training. Training is typically split between 3 groups:

Technical super-users: People responsible for entering and maintaining SKU information in the product database.

Engineering: People responsible for physical system maintenance.

Operators: People who use the system daily to run jobs on the packaging line.

The total amount of training will depend on the number of people in each category and your own production schedule. For a site with 10 packaging lines, we would expect a minimum of 5 days of on-site training to cover all 3 groups.

The majority of retailers also request the system is audited annually by the technology supplier to ensure the system if functioning correctly.

Additional system functionality

Label and date code verification systems typically offer additional functionality to help improve payback and offer a seamless user experience. Typical additional functionality includes:

Downtime recording and reporting – OEE. The same system infrastructure (line terminals, database etc.) can also record downtime and pack counts for OEE and other performance measures. Pack count sensors will need to be installed and software configured. There will likely be additional software licence costs. Prices will likely vary from £5,000 to £12,000 per packing line.

Date code verification (optical character verification). Read back the printed date code on the pack and verify it’s correct to the currently running job. Additional cameras will need to be installed and commissioned to take the pictures. A central high powered server is required to process the images. Prices will typically start from £12,000 per packaging line subject to specific requirements.

Integration of the system with planning/ERP/MES software. The master product database can be populated from your existing ERP or MES system.

Paperless quality assurance. Often paperless quality checks are included free of charge with a “standard” label and date code verification system.

Checkweigher and other device reporting.

Next steps

Putting this all together, a budget turn-key price per packaging line with 2 scanners (top and base label) and one printer connection is £18,000. As highlighted, there are a number of factors that can push this price up and down. Savings can also be made when buying multiple lines and software licenses at the same time. The only way to know exactly how much a label and date code verification (Autocoding) system will cost is to schedule a site visit for an experienced engineer to review your requirements and create a solution for your business.

Top 7 reasons for switching to robotics

Many industries have yet to take advantage of robotics. Yet there is so much that’s ripe for automation, particularly when it comes to automating processing tasks. Here we outline the top 7 reasons for switching to robots in your processing.

Many industries have yet to take advantage of robotics. Yet there is so much that’s ripe for automation, particularly when it comes to automating processing tasks. This activity offers significant value, not just in terms of cost savings but also to achieve a step change in quality and traceability. Here we outline the top 7 reasons for switching to robots in your processing.

1) 24/7 reliability

Productivity is a challenge all over the world, and one that has been further impacted by COVID-19. For example, the UK has seen reduced productivity growth over the last ten years, as output per hour and real wages remained no higher in 2020 than they were pre-2008. It’s clear that we all must do something different to produce a step change.

While labour has traditionally been the answer to reduced productivity in many industries due to its flexibility and cost-effectiveness, robots are inherently more reliable than humans. With a mean downtime of 30 minutes per year, they also don’t need to stop to maintain their effectiveness, helping to boost your productivity. This means that they can operate 24/7 with increased levels of accuracy when compared to humans and with zero risk of cross-contamination

Using robots allows manufacturers to do the same tasks as humans currently carry out but much more accurately, without error or waste, and at much faster rates. This can transform productivity levels, allowing manufacturers to become much more competitive, as well as reducing the costs incurred as only one operator is needed to manage the system.

2) Affordable automation

The cost of robotics is coming down, just at the point when the cost of labour is increasing across the globe. The processing stages in many industries can be particularly affected by these rises due to the number of operators usually involved.

The living wage in the UK is currently at £8.91 (as of April 2021), and is set to rise further so it’s easy to see how these labour-intensive tasks add up and can start to chip away at your bottom line. In addition, rising production costs and cut-throat competition across the board require manufacturers to do something differently, which typically means a high degree of automation to increase efficiency. The manpower required to meet your productivity levels can (almost) never be justified, however, if you can find the areas where you have many people doing manual tasks and automate this, the labour cost reduction alone will soon justify the capital investment upfront.

By implementing robotic ingredient handling or batch processing, it’s possible to remove human intervention from traditionally labour-intensive activities, therefore allowing manufacturers to reduce associated labour costs and boost margins.

3) Accuracy and reduced waste

Unfortunately humans are, well… only human! When people are involved in processing, they make mistakes; that’s par for the course when performing repetitive tasks during an eight-hour shift. Unmanned facilities remove this risk as once programmed, robots can’t make mistakes.

Human intervention has been found to be the second largest cause of waste in food production. A major study by Brunel University, London, and Ghent University reviewed the production processes at 47 food manufacturers in Belgium and found that human error is a major cause of food waste, accounting for 10.9%*. In addition, human interaction can also be a source of cross-contamination, which can jeopardise consumer health and should be avoided at all costs.

As we’ve seen in the automotive industry, the benefits of robotics in terms of accuracy, quality and productivity cannot be ignored - it’s time to bring these advantages to more industries.

4) Overcome labour shortages

Whether it’s Brexit or COVID-19 reducing the available pool, we’ve seen that labour shortages are a recurrent problem for many industries and it’s becoming harder to recruit the labour force upon which we have traditionally relied. Many manufacturers have had to meet increased demand with fewer people while also implementing social distancing measures to protect staff, particularly challenging in labour-intensive areas of a facility.

Automation can vastly reduce the number of operators needed, whether it’s upstream in materials handling or downstream on the packaging line, increasing efficiency and accuracy, saving money but also reducing the number of people on what can sometimes be a crowded factory floor. Automation allows manufacturers to deliver their volumes and keep their people safe.

By investing in fully automated manufacturing systems, companies can mitigate the impact of labour shortages and improve profitability at the same time. To do this, the traditionally complex, labour-intensive manufacturing processes must be converted fully to automated operations and critically this means matching the full flexibility of manual operations. Furthermore, automation can simplify the tasks completed by operators, reducing reliance on highly skilled individuals.

5) Operator health & safety

Working with many raw materials, from powders to harmful chemicals, every day in manufacturing facilities can pose a significant risk to operator health as exposure to dust can cause occupational asthma and rhinitis. What’s more, lifting and tipping sacks of ingredients all day, every day can cause musculo-skeletal disorders.

Manufacturers must mitigate this risk and the best way to achieve this is to remove the operator from the activity by automating the tasks, protecting operator health and allowing them to move into more value-added roles.

6) Batch of 1

Production lines that can adapt to rapid product changes, customisations and small batch sizes are vital in today’s manufacturing environment. From changing consumer preferences to fluctuating raw material prices it pays to have the ultimate flexibility in your production. Consumers have begun to expect personalisation and customisation in their purchases - fulfilling these by hand would be too expensive, but robotic systems that can adapt and cater to consumer trends will keep themselves ahead of the competition.

To take advantage of this trend for personalisation, smaller batches are required so manufacturers can easily switch to meet customer requirements rather than the bulk processing approach that has been standard. This is where robotic solutions, such as the APRIL Robotics Robot Chef is ideal as you can produce 600L batches and operate much more flexibly to adapt to these growing trends. There are different programmes depending on what is needed for a given run, allowing manufacturers to adapt for a wide range of variables. An operator merely needs to select the correct programme and the robot takes care of the rest. Very little expertise is needed to operate these systems, and no extra time is required to make the change, bringing all of the benefits of robotic automation.

7) Traceability

With total traceability for your product and a full audit trail, robotic systems can help to prevent product recalls. By linking your system to your ERP, you’re able to track all of your ingredients throughout the entire process to give you a real-time view of your operations.

Working with a dedicated partner like OAL can help manufacturers to realise all these benefits whether it’s starting small or a more radical transformation. From system studies to 3D factory scans, we can ensure you achieve the right results with a clear financial justification for the investment to deliver ROI in under 24 months.

Ready to join the robotic revolution? Get in touch today!

Can robots replicate the flexibility of operators?

For a number of years now robots have been employed on the production and packaging lines. But what about robots in processing? Automation has been largely under-utilised in this area as humans have traditionally offered the greatest flexibility, but is this still the case? Here we explain how robots are more than up to the task.

For a number of years now robots have been employed on the production and packaging lines, taking care of standardised and repetitive tasks. But what about robots in processing functions? Automation has been largely under-utilised in this area as humans have traditionally offered the greatest flexibility, but is this still the case? Here we explain how robots are more than up to the task.

Operator flexibility

The challenge with any automation project is that people are hugely flexible; they can move from one task to another seamlessly, for example changing quantities of raw materials from one batch to the next and switching outputs at a moment’s notice. Labour in the UK and many other countries has also traditionally been highly cost-effective, which made humans an ideal solution on the processing line, scaling up and down to meet demand.

But as labour costs rise and skills shortages, as well as operator availability, continue to hit all industries hard, it’s clear we need to re-evaluate our reliance on operators and explore new automation opportunities to future-proof production.

It’s understandable that some manufacturers feel that robotics will never be able to replicate the flexibility of a person. It’s often assumed that robotic engineers will be needed onsite to set up each line and make the necessary programming updates for each product changeover. Not only would this be time-consuming but most manufacturers wouldn’t have access to engineers with this sort of expertise, which has meant that robots haven’t appeared to be a viable solution for lines with multiple changeovers. Yet with the right solution, this is not the case at all. Manufacturers need robotics systems to be easily configurable for different products or raw materials and able to adapt to the changes that inevitably occur within any manufacturing facility. With their speed and agility, robots are ideally placed to handle frequent product changes as is often required in today’s manufacturing environment, particularly as we must increasingly cater to the batch of one.

Robotic accuracy

When assessing operations to automate, it can be easy to miss certain vital tasks that operators complete. For example, if you take an operator who weighs out powders to a recipe, on the face of it the primary task is weighing. However, the person is also conducting various secondary tasks, e.g. validating the raw materials and their quality, locating the raw material, cleaning etc. If these secondary tasks aren’t incorporated into the robotic solution, the system won’t offer the required performance. It’s important to fully evaluate the full remit of each operator to understand the exact scope of the solution required to deliver positive results from day one and ensure no flexibility on the line is lost.

If, for example, you’re looking for a robotic solution to powder weighing with frequent product changeovers, the first question to answer is, how to define flexibility? In the case of the APRIL Robotics Weighing System, flexibility is defined by the number of raw materials stored and the dosing range. In this instance, the use of robotics gives us a wide operating envelope. This means that, for example, we can go from weighing out a small batch of cocoa powder to a large volume of salt in the same operation with no cross-contamination or time-consuming set-up as the robot is designed to work flexibly. The system has different programmes depending on what is needed for a given run, allowing manufacturers to adapt for a wide range of variables. An operator merely needs to select the correct programme and the APRIL Robotics Weighing System takes care of the rest. Very little expertise is needed to operate the system, and no extra time is required to make the change, bringing all of the benefits of robotic automation, such as increased accuracy and uptime, without the concerns around flexibility that many manufacturers have.

How to build a case for robots

System studies are a great way to explore automation and how it would meet your requirements without risk or commitment. You can trial your processes on our test equipment to understand how robots would fit into your processes and gain a realistic idea of the return on investment you’re likely to achieve. This makes the whole process a lot safer, not only because you can be sure our robotics solutions will work in your facility but also because it makes it easier to put the financial justification to the business when there is a clear roadmap for payback for the upfront investment.