Robotics & Food Manufacturing 4.0. Are you ready?

Whether robots really belong in a food factory is becoming a no-brainer. In order for the food industry to improve and grow, robotics and automation WILL play a major role in the food manufacturing process. Andrea Paoli reveals how robots have taken root so far in our manufacturing systems and are set to revolutionise the food industry in Food Manufacturing 4.0 and beyond.

The value of robotics

Andrea Paoli presented a number of very enlightening figures when introducing the impact robotics will have in the future. Here are a few to set the scene:

The Bank of England in November 2015 predicted that over the next decade, 15 million jobs will be taken over by robots.

In 2020, the robot market is expected to hit a value over $83 thousand million.

It’s predicted that the global saving for using robotics in terms of labour cost is 16%.

By increasing investment in automation by £1.2 billion, this could raise the overall value added by the manufacturing sector to the UK economy by £60.5 billion. This could safeguard 106,000 jobs.

Since the industrial revolution, robots have gone from mechanical production equipment driven by water and steam all the way to cyber-physical systems which integrate computers, networking and physical processes. The degree of complexity of robotics is forever increasing. As you can see from the videos in Andrea's slides, the capabilities of robotics and automation have increased and improved dramatically. Is there anything they won’t be able to do?

So what does Food Manufacturing 4.0 look like?

Robotics and automation have progressed in such a way that it’s safe for them to work in collaboration with humans (HRC systems - Human/Robot Collaborative systems). They can work to full capacity 24/7 producing the same results they’re programmed to complete. This is impossible for humans to achieve to the same degree of accuracy and consistency.

Therefore, there is a massive opportunity for an increase in productivity for food manufacturers due to the reduced cycle and turnaround times. A robot can work within stabilised conditions without human interface. Not only does this improve the health and safety of the factory, it can also increase the shelf life of products contributing to reducing waste which is a very hot topic at the moment!

Working together with the University of Lincoln, OAL has been championing Food Manufacturing 4.0 and have developed a robotic chef APRIL. APRIL is facing up to the challenges food production is facing to introduce a flexible, automated, continuous, high volume system to food manufacturers. Read more about APRIL and her talents here.

How will a future food factory look?

A factory of the future will run on big data being used intelligently to improve decision making and planning. Cloud computing will allow for anything to be controlled, recorded or reported in real-time. With humans collaboratively working together with robots along with all the big data that will be available, factories will be able to optimise production, reduce wastage and improve product consistency and quality.

Join OAL on this journey by helping us educate the industry to deliver disruptive change in manufacturing securing your factory’s future as well as the future of the food manufacturing industry.

Ann Savage on the future of chilled food manufacturing

What is the right environment for chilled food innovation? Ann Savage, former Group Technical Director at Bakkavor, spoke at the Food Manufacturing 2030 Conference on the future of chilled food over the next ten years. Discussing the rise of new technologies including robotics, Ann highlighted the pressing need for food manufacturing to create the right conditions for successful innovation. After discussing a number of the wide-ranging challenges food manufacturing faces including environmental and significant cost pressures Ann stressed the importance of creating the right conditions for innovation in the UK. Collaboration between research institutions, technology providers and manufacturers will be very important in realising new developments. Likewise, further investment is needed in skills to realise the benefits of new technologies.

Ann has seen the tremendous growth of the chilled food market which has leapt from revenues of from £5 billion in 2000 to £11.4 billion in 2014 and is still growing. Discussing the benefits and rise of automation and robotics, Ann highlighted amongst others the following areas of interest:

Longer shelf life

Robots can work within controlled environment with limited exposure to bacteria and allergens often carried by people. There are significant opportunities for improving the shelf life of products, reducing waste and improving the overall safety and hygiene of the factory in this way.

Improve decision making

Automation within a factory can also reduce human decision-making. The collection and intelligent use of big data will allow problems to be resolved before they occur, as their played out in digital factories. This will allow factories to plan further ahead, reduce stoppages and save time on resources.

Farm to fork

Improved data collection and analysis will enhance food safety from farm to fork. Big data applications will enable full visibility of the supply chain with in-line quality checks enhancing protection against errors.

If you’d like to bring these benefits into your manufacturing facility, our experts can help you take the first step.

McKinsey report: where will automation replace humans in food manufacturing

Food service and manufacturing sit at the top of a recent McKinsey report that analysed work activities rather than occupations as a predictor of automation. By identifying jobs with predictable physical work, data processing or data collecting, they were able to assess the technical feasibility of automation. By breaking down jobs by activities, up to 59% of time spent at work in the US is highly susceptible to automation. Further analysis suggested that food service and manufacturing were more suited to automation than others i.e. many activities within food manufacturing are highly susceptible to automation.

Technical feasibility of automation in food

The McKinsey report highlights food manufacturing and food service as highly susceptible to automation due to the activities involved in the jobs (see figure 1). The main driver for this is the high amount of time people spend on predictable physical work. Often in food factories, people will undertake a high number of predictable activities such as lifting product, moving ingredients etc. (see figure 2).

In our experience, the trend fits for our customers who manufacture a smaller range of SKUs and have already been able to automate a high number of the predictable activities. This is in contrast to chilled food manufacturing, where upwards of 40 SKUs can be produced per day and predictable and unpredictable activities become intertwined.

One major part of the puzzle will be splitting out the predictable from the unpredictable physical work, thus enabling higher levels of adoption of robotics. For instance, lifting ingredients into a saucepan is a predictable task but judging the taste of the food requires the expertise of a chef, hence it isn't so susceptible to automation.

We're working with the University of Lincoln to develop robotic systems that provide manufacturers the flexibility to split out the predictable from the unpredictable thus enabling greater levels of automation. APRIL™ the Robot Chef installed at the National Centre for Food Manufacturing enables this flexibility by breaking down activities in a different way to traditional manufacturing processes.

Mckinsey Technical feasibility

Mckinsey industry Feasbility

Making big data small in food manufacturing

Confused about the impact of big data on food manufacturing? We believe many food manufacturers already have the data and our focus is better directed to the meaningful presentation of figures to deliver operational improvements.

Originally featured as a guest article on www.bakeryandsnacks.com

There’s a lot of excitement about the internet of things (IoT) and big data but realistically many larger food manufacturers already have access to lots of data. When we speak with our customers, often the idea of more data is seen as a distraction. There are bigger opportunities for operational improvements in presenting data in an informative and actionable way. For big data to be a success, data must be more informative, actionable and timely.

OAL big data bakery SCADA screen

Informative big data

What use is all the data about a process if it’s not easily understood by engineers and operators? One of the big switches we’ve made on our control systems is how we present data. For instance, when you compare our traditional SCADA screens to our newly developed screens they look completely different. Designed with user experience at its core, the new visuals seek to present information that is much more relevant to the end user. For a bakery process, traffic light systems easily indicate if there are any issues relating to humidity, temperature etc. If they’re all green no worries at all. Likewise representing the flow of product as blocks as opposed to how the system operates clearly indicates bottlenecks and breaks in production.

Actionable big data

Data, no matter what its size, is useful to management, engineers and decision makers when it’s actionable. We’ve brought vegetable preparation lines into the 21st century by providing individual operators a screen with real time yield, production feedback and all their Standard Operating Procedures (SOPs). Previously multiple operators would be reliant on a single beacon to track weight. Now actionable data can be presented on an individual basis to improve yield and performance. For both management and operators, it’s clear if an individual is giving away too much product and both parties have the information to hand to take action.

Timely big data

Reviewing yesterday’s production reports looking for insights leaves manufacturers in a reactive state. Manufacturing excellence requires proactive responses to data. Timely delivery of data removes distractions and allows operators and engineers to focus on the job at hand until required. Simple things like changing the colour of a screen from blue, when the downtime is planned, to red, when the downtime runs over are easily understandable.

OAL Factory Performance Changeover

Big data has the potential to be extremely powerful but only if it’s presented in a timely, informative, actionable manner to end users - take the first step today!

Time to act: robotics in food and beverage manufacturing

APRIL™ Robot Chef

Food manufacturing is facing a perfect storm driven by the living wage; flat line productivity and food deflation. Advanced technology and robotics can address these issues yet the UK is seriously lagging behind the developed world in its implementation. The Office of National Statistics recently announced that the UK has returned to recession for the 3rd time in 8 years. A dive in productivity further underlines the challenge in the UK manufacturing sector. The UK now has a 30% lower GDP per hour than countries such as the US, France and Germany. It must be time for food and drink, the largest manufacturing sector in the UK, to act.

The impact of robotics

In 2014, global robot sales increased by 29% to 229,261 units with the main growth seen in the automotive industry, representing 40% of all robots sold. The UK food and drink sector has a 10-year average adoption rate of just 63 robots a year!

China has expanded its leading position in the adoption of robotics with 25% of the total supply in 2014. High productivity countries such as Germany, France and US show a strong correlation to the number of robotic installations, with the US and Germany featuring in the five countries accounting for 70% of all robot sales along with China, Japan and Korea. France also increased investment in robotics, while the UK’s commitment has been in decline. The forecast for robotic installations sees China looking to around 150,000 by 2018, double the 2014 levels, compared to the UK whose outlook is relatively flat during the same period. The other industrial nations have shown steady growth during the same period.

With the food and beverage sector at such low levels of commitment and as such an important economic contributor, the use of robotics must become part of the vision for the future food factory, and the move to Food Manufacturing 4.0.

Barclay’s bank (2015) forecasts that an investment of £1.2bn in automation will add £60bn to the UK economy, ultimately safeguarding 106,000 jobs. Barclays note that the food and drink sector would be one of the primary sectors to benefit, with productivity improvements of 25% being achieved by 2025. Early indications are proving that embracing automation has enhanced productivity and lead to job creation.

Global centre of excellence for robotic food manufacturing

Working with the University of Lincoln we have been championing Food Manufacturing 4.0 and have developed the transformative APRIL™ Robot Chef. APRIL is challenging the way food production lines are set out, moving away from ‘traditional’ linear continuous production, where high volume and limited flexibility have been the watchwords. APRIL will deliver a system that introduces a return to flexible batch systems, but with intelligent and integrated scheduling that optimises production, improves efficiency and in doing so enhances productivity – Potentially more traditional than continuous linear systems in reality?

At the successful launch of the APRIL Robot Chef in April, we set out our vision to create a Global Centre of Excellence for Robotic Food Manufacturing at the University of Lincoln to:

Educate the industry.

Partner with visionary early adopters.

Deliver disruptive change in manufacturing.

If you’re interested in transforming your facility and bucking the productivity trend, get in touch with our experts!

What's driving the UK bakery industry forward?

Parts of the UK bakery industry have recently made significant investments to replace ageing bakery lines with highly efficient new equipment. As the part of this five-year investment, Olympus Automation has been the largest UK supplier of turnkey flour and minor addition plants with a total market value circa £30 million. State-of-the-art systems use the very latest vacuum technology and are achieving world class accuracy as well improved energy efficiency. The systems incorporate hygienic design throughout which has been optimised for minimal maintenance.

As in most industries there is a major drive for exceptional efficiencies, be this in the form of waste reduction or improved efficiency. There is also a great desire to improve product quality and have the flexibility to meet consumers’ demands for more varied bread products with additions of minor ingredients. Unrelenting consumer demand means that during projects bakeries have to maintain a 99% order fulfilment presenting significant challenges that Olympus Automation had to overcome.

How to achieve a fantastic product?

Fantastic bread is soft, has a good crumb structure and retains a high degree of freshness. Aside from excellent raw materials an accurate and automated process is critical in delivering a consistently great product. Superior SCADA control and automation has facilitated big improvements in the consistency of product as the process becomes highly controlled and dependable.

Waste reduction

Accurate dosing and monitoring of total plant performance allows plants to understand and target waste at their sites in a much more dynamic manner. SCADA plant visualisation clearly highlights areas of waste and loss in performance, prompting action. Improved powder handling and dosing accuracy reduces material and energy waste.

“To be excellent, everything that you do needs to be excellent. A big part of being excellent comes down to the design of the bakeries in which all aspects of safety, efficiency and ergonomics were considered. The powder handling systems installed are innovatively designed to maximise performance within the bakeries and achieve outputs of 10,000 loaves per hour.”

Maintaining order fulfilment

Due to the high demand for product in the UK, maintaining order fulfilment whilst major projects are being undertaken is of the highest priority. Manufacturers cannot afford to disappoint customers with missed order when investing for the future. Tackling this requires a very high attention to detail in the planning phases and execution to plan or orders would be missed. Robust systems and experience in the industry allows suppliers like ourselves to consistently deliver to plan.

Product variety

The industry has become more finely tuned to consumer’s different tastes and nutritional demands and matching this demand requires more variety and flexibility from bakeries. Minor additions to recipes have become critically important in offering many different varieties of loaf, with recipe content such as fat, yeast and provers changing to reflect individual’s preferences. These variations force bakeries to adopt robust automation systems to ensure recipes are correctly adhered to and orders fulfilled.

New liquid dosing technology

Outdated liquid dosing systems in bakeries have led to unnecessary ingredient wastage and slow delivery times. Patented Batchmate™ technology offers a saving of at least 10% on raw ingredients with an unequalled liquid dosing accuracy of 5g in volumes up to 2kg and 0.1% in all volumes above. Dosing time is reduced by 20% compared to traditional methods because the system allows for a significantly higher velocity of delivery.

If you’re ready to transform your operations too, it pays to work with an experienced partner. Speak with our experts today and we can help you get started!

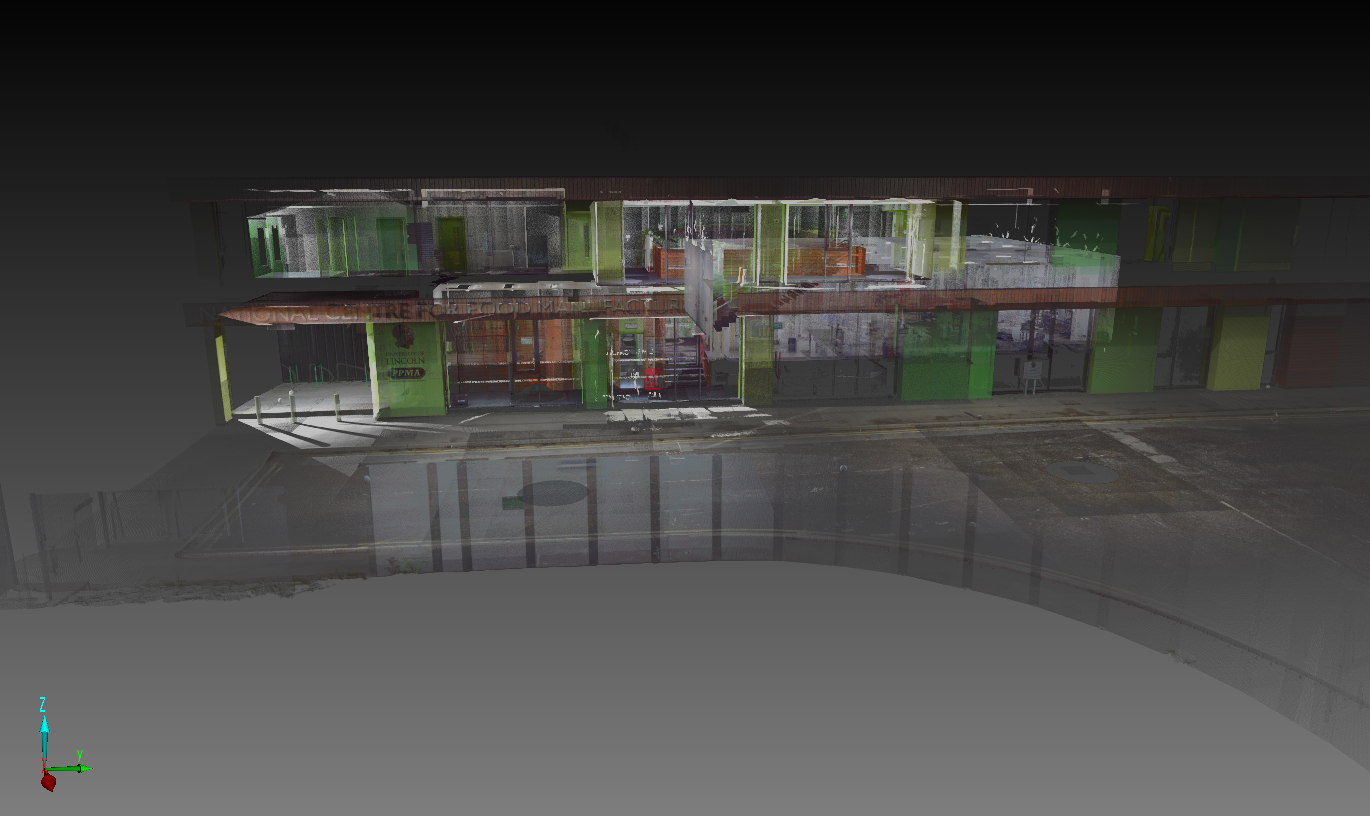

Will 3D factory scanning improve food factories?

3D scanning is used extensively for industrial design and in the production of movies and video games but does it have value for use in the food factory? In the ideal world every factory would have accurate, fully dimensioned, 2D/3D drawings of every part of the facility so that new plant modifications can be easily designed. Whilst this will be in place for new plants, at OAL Group we have found in most cases the first step for plant remodeling, is a time consuming measurement and drawing process.

For complex plants this takes too long and it can be difficult to attain high levels of accuracy. This lack of visibility often means that initial discussions of new layouts, at a senior level, are delayed or made worse by relying on inaccurate layouts.

How does 3D scanning work?

The most common scanners for this purpose are tripod based with a rotating scanner and camera, with the camera there to colour the scan points. The laser scanner uses phase shift to measure the distance between points from the scanner location. At each position the scanner captures hundreds of thousands of measurement points per second in a full 360° data capture, creating a complete sphere pattern of dot positions. As equipment within the room obscures the scanning process multiple scans from different position are required to obtain information about all sides of the area contents.

Once multiple scans for a single area are complete post processing stitches together millions of data elements into a ‘point cloud.’ The process is then repeated for other factory areas with post processing including joining individual ‘point clouds’ together creating a ‘project point cloud’ of the entire site.

The outcome

The results of the process permits a 3D ‘walk through’ of ‘as installed’ plant to a measured accuracy of up to 2 mm, with the ability to dimension and add annotations to any 3D element. That means plant remodeling is based on accurate data making the design process much quicker. It also means that reverse engineering of assets and components is possible. Whilst 3D CAD uses are likely to have powerful workstations to access the files, standard users are supported by a secure web application allowing unlimited views within the organization on standard desktop pcs.

The accuracy is so good that at a recent exhibition many visitors thought the 3D scanned images where videos until they were shown how to ‘walk-through’ and measure elements.

3D scan to CAD is twelve times faster than manual measurement

Applications in the factory

Whilst 3D scanning for video games and the entertainment industry may be exotic, there are many uses that could be considered for factory use with implications across a number of key disciplines in the industry.

Import to 3D CAD

This is probably the most obvious requirement for project engineering and maintenance teams. The 3D scan to CAD process is twelve times faster compared to manual measurement with much higher accuracy rates. The point clouds are imported into software that sections the point cloud and uses the points to create geometry, a bit like tracing in 3D. The days of tape measure, paper and camera to create CAD layouts must surely be coming to an end.

The three step process of 3D scan - Point cloud - 3D Cad means that by step 2 the 3D walk-through and ability to dimension and annotate is available within a few hours. That means benefits are gained whilst work continues on the final step, the import to 3D Cad for further design work.

It is estimated that, whilst import to CAD is important, a much as 60% of the benefit for the factory team could be gained once the point cloud has been created at step 2.

Supplier review

Want a potential supplier to quote for plant modifications but don’t want him to see the full site? Don’t have time for the supplier to arrange a site visit? Give him secure web access to a restricted part of the plant from his own location. The ability to walk-through and dimension allows both parties to view simultaneously and compare ideas and thoughts on line. That allows more potential suppliers to be involved and reduces the time to project quotation.

Reverse engineering

Have failed asset components from obsolete equipment, or missing CAD files from an old project? Use 3D scanning to quickly digitise a part and create a fully surfaced CAD model which can then be used to reproduce a local copy. There is no effective limit in terms of size, with larger and more complicated items just needing more scans.

Plant reviews

The regional management team wants to quickly review plant layouts. Of course a ‘Genba or Gemba’ visit to the manufacturing floor is better but for an initial check or quick safety review a 3D walk-through will be quicker and much more realistic. The ability to dimension also means that initial assessments can be made to see if the new kit could possibly fit in that position.

Asset register

Creating an asset register from scratch takes a long time and it’s not unusual for the process to take months. Whilst a 3D scan won’t identify the plant nameplates or serial numbers it’s a great start and will speed up the equipment identification process. Database links can be made in both directions with the 3D scan point cloud able to load an asset register and the asset register, in turn, able to load the 3D scan point. The is no reason why the process cannot be part of maintenance checks with the inspection content linked to, and taking the engineering to, a precise location in the 3D scan point cloud for a physical review.

Incident investigation

One final application you may hope not to use. Forensic crash investigation allows data to be recorded for office based analysis and supports vehicle deformation comparison against standard measurements. Could those techniques be used for industrial incidents, almost certainly?

Being able to walk-through an accurate 3D layout increases plant visibility significantly, it’s as close as you can get to being there in the room. The tools are here to stay with more uses being identified daily. Try it out and you'll wonder how you managed without it.