OAL Featured on BBC Climate Documentary: Ready Meals – What They Really Mean for You

We’re proud to announce that OAL has been featured in the BBC’s new documentary Ready Meals: What They Really Mean for You, now streaming on BBC iPlayer.

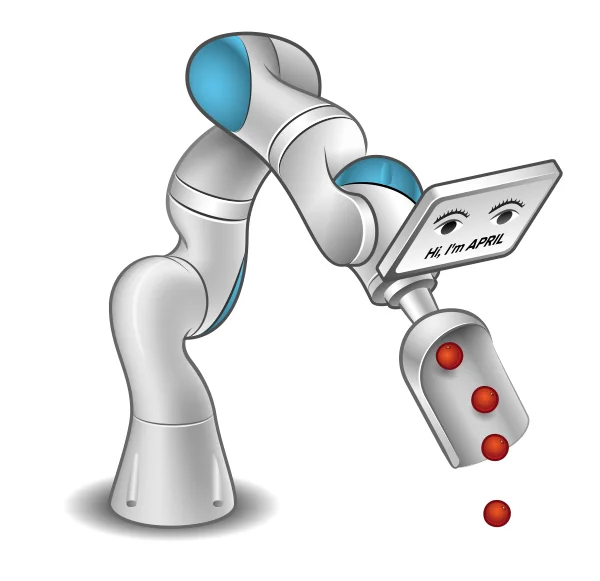

The programme explores how food production can achieve net zero, and the innovative technologies helping to do it. Our APRIL™ robotic chef and Steam Infusion technologies are featured, demonstrating automated cooking at scale while cutting energy, water, and chemical usage.

The system was developed as part of Project Souper Green - our £2 million collaboration with Solina and Marks and Spencer, part-funded by the Department for Energy Security and Net Zero through the Industrial Energy Efficiency Accelerator, delivered by The Carbon Trust in partnership with Jacobs and Innovate UK.

Being featured on the BBC is a proud milestone for our team and a clear signal that automation and robotic solutions have a central role to play in decarbonising food production.

Watch the episode on BBC iPlayer to see how OAL delivers practical, scalable solutions for a more sustainable future. (OAL segment at 16:35)

Want to automate your food business? Get in touch to explore what’s possible.

Automation Trends in Food Manufacturing Seminar Series

Join our exclusive seminar series tailored for leaders in food manufacturing. Discover innovative technologies, engage in insightful discussions, and gain a competitive edge.

Automation is reshaping the future of food manufacturing, and this seminar series is your gateway to staying ahead. From artificial intelligence to robotics, our events are designed to showcase advanced solutions and spark meaningful conversations among industry leaders.

What You’ll Experience:

Live Demonstrations

Get to grips with the latest robotic and vision technologies shaping food manufacturing

Interactive Discussions

Participate in breakout sessions on automation trends, challenges, and opportunities for tailored solutions.

Networking Opportunities

Connect with industry experts, academics, and peers driving innovation in food manufacturing

Why Attend?

Exclusive Insights: Gain knowledge on cutting-edge automation trends and practical applications.

Tailored Solutions: Explore how automation can meet your specific operational needs.

Actionable Takeaways: Leave with clear strategies to implement and drive ROI in your business.

Register Your Interest

Complete the form below to express your interest. One of our team members will contact you shortly to confirm your attendance.

Upcoming Seminars:

Tuesday 25th February - FULLY BOOKED

Thursday 27th March

Thursday 15th May

Tuesday 3rd June

Thursday 4th September

Tuesday 6th November

Location:

All our events are held at OAL’s headquarters.

Address: OAL, A1 Parkway, Peterborough, PE2 6YN

Movember 2024 at OAL in aid of the Northamptonshire Charity Stroke Team Charity

This Movember, our team supported the Northamptonshire Healthy Charity by growing moustaches and raising awareness for their vital work.

Together, we raised a fantastic £2,820.00 to help support the Community Stroke Team with their amazing work!

This campaign has been about more than just questionable moustaches – it’s been about making a real difference. Every penny donated goes towards vital projects helping people and their families work through illness and the road to recovery.

Andy’s Story

Support for Stroke survivors is a cause very close to our hearts.

Last year, our colleague Andy, a popular presence in the office, suffered a stroke. Thanks to the exceptional support from medical services, especially the Community Stroke Team, Andy was able to achieve his primary goal of returning to OAL, a journey that has inspired us all.

This year, we rallied together to support the Community Stroke Team at the Northampton Health Charity and the invaluable work they do.

Every generous donation went towards helping people and their families work through illness and the road to recovery.

“I'm very proud of our team for taking on Movember to raise money for the Stroke Team!” enthused OAL Managing Director, Jake Norman. “If you've been lucky enough to work with Andy Sillence, you'll know he is Mr Sunshine Yellow. Following a stroke last year, we've been astounded by the grit and determination he has shown to return to work and we're thrilled to have him back! It was an obvious choice for us to raise money and awareness for the charity that supported him this Movember.”

About the Northamptonshire Community Stroke Team (CST)

The Northamptonshire Community Stroke Team (CST) is a respected service that focuses on delivering high-quality, tailored rehabilitation for stroke survivors. Their multidisciplinary team, including physiotherapists, occupational and speech therapists, rehab assistants/practitioners, and nurses, collaborates to help patients recover from, illness and regain independence.

Find out more about the amazing work the Community Stroke Team does HERE.

3 Key Takeaways from PPMA 2024: Showcasing the future of automation in food manufacturing

Our team exhibited at the PPMA 2024 show at the NEC, Birmingham in September. We showcased a number of cutting-edge automation technologies that are helping food manufacturers automate their food production lines. Here’s our 3 key takeaways from a very busy show:

1 - Automation is king!

Across the three days, we spoke to 782 food industry professionals.

Their feedback was clear: the industry is hungry for automation!

From fresh produce to bakery, each sector is suffering with labour availability and rising costs. People recognise automation can help and they’re looking for solutions.

It was great to share how we’ve helped food manufacturers like Worldwide Fruit and Agrana on their automation journey.

2 - AI-powered vision and 3D laser technology took centre stage!

If you fully automate your production lines, no human eyes will see your packs or products!

You’ll be reliant on technology to verify the quality of every pack.

We demonstrated how AI-powered vision technology is a game changer for inspection and a key enabler in their automation journey.

In the first demo, “Right Product” verification; the camera checks that the right product is being packed, for instance, detecting the difference between lasagna and a pasta bake.

The second demo, showed our 3D laser scanning solution showcased how we can create a 3D profile of every dough to eliminate defects and measure critical quality attributes like volume.

Jake Norman, OAL's Managing Director speaking with Camilla Young, Programme Lead for GS1 powered QR codes

3 - Leading the “Second Barcode Revolution”

Barcodes are changing!

We hosted a seminar with GS1 on the “Second barcode revolution” and how best to implement dynamic QR codes on packaging.

The change will require manufacturers to print key production information including batch numbers and date code information on pack.

We have proven solutions that can help you meet the GS1 requirements fast.

Read more about the introduction of dynamic QR codes in The Grocer article here.

OAL will be exhibiting at PPMA 2025. We look forward to welcoming you back next year as we continue to push the boundaries of innovation and provide the solutions that help drive the industry forward. Stay tuned for what’s to come—next year’s stand will be one you won’t want to miss!

The Grocer: The Second Barcode Revolution

A special report by The Grocer featuring OAL's Jake Norman, exploring the many opportunities the global transition to QR codes to industry and consumers alike.

OAL’s Managing Director, Jake Norman, was featured in a recent article by George Nott on “The Second Barcode Revolution” for The Grocer.

George’s report gives a fantastic overview of the power of these next-generation QR barcodes and why adoption is rapdily accelerating across the retail sector.

Please click on the button below to read the feature in full:

OAL appoints Nick Taylor as Operations Director

OAL, a market leader in automation, robotics and digital transformation solutions for the food manufacturing sector, has appointed Nick Taylor as its new Operations Director. Nick will be responsible for scaling business operations to meet the growing demand for OAL’s solutions.

Nick, far left, at a recent site visit to OAL's customer, Worldwide Fruit

“We are extremely pleased to welcome Nick to OAL,” said OAL MD Jake Norman. “Nick has extensive experience across all facets of food manufacturing and will ensure we continue to delight our customers as the business expands.”

Previously, Nick led Capital Investment at KraftHeinz, Telford and served as Site Director at one of Hovis’s manufacturing sites. Over the course of three decades, he has held operations and engineering roles at manufacturers, including Bakkavor, Coca-Cola Enterprises and KraftHeinz.

OAL was founded in 1993 by Harry Norman and quickly developed a strong reputation for pioneering the latest technology to solve the challenges faced by the food industry. From integrated MES/SCADA factory control systems to AI cameras verifying product packaging, date coding and robotic weighing systems, OAL has become the partner of choice for food manufacturers on a digital transformation journey.

Visit OAL at the PPMA Show on Stand A54, 24-26 September 2024

OAL leads “Second Barcode Revolution” roll-out to cut food waste

OAL, a leader in food manufacturing automation, is delighted to announce the launch of its latest software solution for creating, printing and verifying data-rich, on-pack QR and 2D codes designed to meet consumer demand for greater transparency of ingredient origins and methods of production. The software allows unique traceability and manufacturing data to be incorporated into on-pack 2D codes, improving consumer experience to identify allergens, significantly enhancing food safety and reducing food waste by up to 40%.

The OAL solution enables the creation, inline printing and verification of on-pack QR/2D codes containing critical information such as best-before date, allergens and batch data. The solution is in conformance with the GS1 Digital Link standard enabling consumers to access detailed product information in what is being called the “second barcode revolution”, while also enabling retailers to manage inventory more precisely, quickly identify expired products and provide consumers with detailed product information. OAL install inline camera technology to verify the integrity of every QR/2D code printed.

Leveraging GS1's barcode technology, OAL aims to enhance supply chain efficiency and product traceability. The OAL QR code solution stemmed from an initiative led by Tesco to reduce food waste in the supply chain. Tesco’s new initiative allows packs to be scanned by smartphones, and at the point of sale, sharing more information with consumers than the finite space on pack and standard barcode can offer.

Jake Norman, Managing Director, OAL, comments, “Our automated control systems already collect and store huge amounts of traceability data to ensure food safety. We know at a pack level the exact time and raw materials that have been used to make each product controlled by our system. The use of QR codes and the GS1 Digital link is a great way to expand the use of this data to grant consumers the transparency they’re urgently seeking and drive down food waste.”

OAL has pledged to support all manufacturers in integrating a range of QR/2D codes to their process, facilitating seamless data sharing and improving food safety. This comprehensive data ensures product authenticity and simplifies recall processes. OAL’s printer agnostic solution can integrate and control all printer brands. The solution can be retrofitted to existing packaging lines. The solution is available now for new and existing customers.

For more information, please visit https://www.oalgroup.com/gs1-new-barcode

7 Key Moments from Anuga FoodTec 2024: Where AI Vision Tech and Robotic Automation Took Centre Stage!

Last week, our team embarked on an exciting journey to Cologne, Germany, where we showcased our cutting-edge AI vision technology and robotic automation at the one and only Anuga FoodTec Exhibition.

Last month, our team travelled to Cologne, Germany, where we showcased our cutting-edge AI vision technology and robotic automation at the one and only Anuga FoodTec Exhibition.

Here are the top 7 moments that put OAL on the centre stage.

1. Robots Ruled the Roost!

Our robotic weighing system and cooking system stole the show with its mesmerising precision and efficiency when weighing raw materials. Manufacturers were relieved to find a solution to overcome their ongoing labour availability challenges.

2. AI Vision Tech Magic!

Say goodbye to human error and hello to precision perfection! Our AI vision technology wowed the crowds with its ability to analyse products from component recognition to date code verification and even checks for allergen information.

3. Busiest stand award 2024!

Anuga FoodTec was the ultimate playground for innovation, and we were proud to be at the forefront of the action. We even won the award for most popular stand, with over 500 registrations recorded, that’s a lot of demos.

4. Interactive Experiences!

Who says tech exhibitions have to be boring? Gone are the days of highly choreographed software demos. Visitors got to choose the inspection and we showed them how to train the AI and make the check in less than 5 minutes! The result? Smiles, laughter, and a newfound appreciation for the magic of OAL’s APRIL Eye.

5. Tech Talks Galore!

Knowledge is power, and we were thrilled to share our expertise with eager attendees. From demystifying AI to exploring the future of robotic automation with weighing and cooking, we left no stone unturned in our quest to educate and inspire.

6. Industry Insights!

Anuga FoodTec wasn't just about showcasing the latest technology—it was also a hub of industry insights and trends. From the rise in codes of conduct to the growing demand for sustainable food tech solutions, we gained invaluable knowledge that will shape the future of our industry.

7. Networking Nirvana!

Anuga FoodTec brought together the best and brightest minds in the food tech world, providing the perfect opportunity to connect, collaborate, and forge new partnerships.

Our time at Anuga FoodTec Exhibition was inspiring. It was a celebration of innovation, creativity, and the boundless possibilities of AI, automation and robotics, with OAL positioned as a strong leader in game-changing solutions in food manufacturing.

OAL appoints Jake Norman as Managing Director

OAL, a market leader in automation, robotics and digital transformation solutions for the food manufacturing sector, has appointed Jake Norman as its new Managing Director. Founder, Harry Norman will remain on the board.

Jake Norman has over a decade of experience in automation and a proven track record of developing long-term customer relationships. He joined the board two years ago as Sales Director, taking P&L responsibility for the business and winning a number of new customers. Notably, he has recently secured a £2 million part-government funded Carbon Trust project to deploy the company’s robotic chef with Marks & Spencer and Solina.

“I’m proud to lead the family business into a new era as we navigate the fantastic opportunities automation and robotics present to our customers,” comments Jake Norman, Managing Director, OAL. “We’re inspired by Harry’s visionary approach to automation, he’s built an exceptional engineering team that help our customers succeed and I’m looking forward to building on this foundation.”

OAL was founded in 1993 by Harry Norman and quickly developed a strong reputation for pioneering the latest technology to solve the challenges faced by the food industry. From integrated MES/SCADA factory control systems to AI cameras verifying product packaging and date coding and robotic weighing system, OAL has become the partner of choice for food manufacturers on a digital transformation journey.

Harry Norman, Founder, OAL added, “Jake’s passion for technology and his understanding of the food manufacturing sector make him the ideal leader for OAL as we look towards an exciting future. I am proud to see him take on this role and have every confidence in his ability to steer OAL to new heights.”

Visit OAL at Hall 10.1, Stand F-069 at Anuga Foodtec Cologne, Germany, 19-22 March 2024 to learn more.

OAL 3 Peaks Challenge 2023

We’re hiking the 3 Peaks in June to raise money and awareness for the charity StrongMen, a local mental health charity that has supported colleagues with challenges arising from bereavement.

We’re hiking the 3 Peaks to raise money and awareness for the charity StrongMen, a local mental health charity that has supported colleagues with challenges arising from bereavement.

In June, a team from OAL will be putting down the tools and stepping away from our keyboards to take on the 3 Peaks Challenge in under 24 hours!

The 3 peaks are made up of Ben Nevis (1,344m), Scafell Pike (978m) and Snowdon (1,085).

We‘re starting on Saturday 23rd June with Ben Nevis, hopping in the van down to hike Scafell Pike, and finishing in the early hours of Sunday morning at the top of Snowdon.

Will it be a software, mechanical, design or electrical engineer to reach the top of Snowdon first?

We’re raising awareness and money for StrongMen, a great local charity that has helped us overcome the mental health challenges of bereavement.

If you would like to donate, you can here: https://www.justgiving.com/fundraising/oal-3peaks

Net Zero Food Manufacturing 2022 Round Up

On 16th June 2022, we explored the routes to net zero food manufacturing at the National Centre for Food Manufacturing (part of the University of Lincoln). A big thanks to our awesome customers, fascinating speakers and cutting-edge technology partners for making it a fascinating day!

On 16th June 2022, we explored the routes to net zero food manufacturing at the National Centre for Food Manufacturing (part of the University of Lincoln). A big thanks to our awesome customers, fascinating speakers and cutting-edge technology partners for making it a fascinating day!

The scene was set with insights and perspectives from academia, energy and finance:

Ling Sin Fai Lam, Shore Capital, highlighted the growing requirements for businesses to validate their “green” credentials.

Grant Barr, EON, explained the changing energy environment as the “spark gap” is reduced and the major benefits of consuming energy outside busy periods.

Wayne Martindale, University of Lincoln, reviewed the food industry's progress in decarbonising and shared the latest research projects in the field.

Bring on the robots!

With the scene set, we were joined by two pioneering food businesses using OAL robotic systems in the processing area to cut energy and improve production efficiency, quality and safety. Followed by a demonstration where we manufactured a net zero soup using the APRIL Batch cooking system.

Bing Go, Go Tan, explained how they have moved from traditional steam jacketed cooking vessels to a fully automated APRIL robotic cooking system.

Benoit Wissoq, Agrana shared their approach to automating powder handling with APRIL Powder Weighing. Watch the video below.

OAL demonstrated the APRIL batch cooking system by cooking and cooling a “net zero” batch of pea and mint soup. Saving the planet never tasted so good!

Alan Oakley, KUKA Robotics talked about how they support OAL with R&D and support customers locally through their extensive network.

Solving the energy problem

As the old maxim goes, what gets monitored, get’s managed. Our ability to collect, the right data, contextualise and drive action is fundamental to improving the energy efficiency of food businesses. Both end user case studies explained the need to put people at the heart of automation programmes.

James Judge, Berry Gardens focused on the need for “story telling” and “de-geeking” as part of the digitalisation of their new packhouse. Watch the video below.

Matthew Beacham, Wealmoor explained the skills and approach to automate their packaging lines and save energy by preventing human error. Watch the video below.

Inductive Automation and Ethan Stone, OAL shared how we use the Ignition SCADA/MES platform to present shopfloor data to end users easily. Watch the video below.

Thomas Flude, Cognex, demonstrated new vision and artificial intelligence technology can be quickly deployed to cut food waste.

Energy reduction funding

In our final session, Mark Swainson, University of Lincoln and Jenni McDonnell MBE, KTN, highlighted the current funding opportunities for energy and carbon reduction projects.

It truly was a varied day and we’re very grateful to all those attendees who came and participated so enthusiastically - we enjoyed every minute!

If you missed the event and want to hear more, get in touch and we can arrange a meeting with our experts.

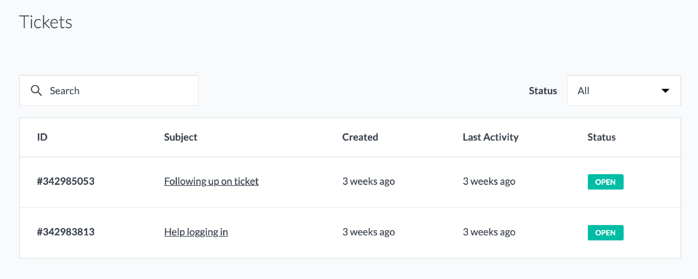

OAL customer support ticket portal

We’re pleased to announce a new feature for our support customers, the ticket portal. The new feature offers visibility and communication history for all tickets raised by your organisation.

We’re pleased to announce a new feature for our support customers, the ticket portal. The new feature offers visibility and communication history for all tickets raised by your organisation.

Customer Ticket Portal

To access the customer portal, please contact OAL and we’ll enable the portal for your account.

You’ll be sent an email to register using your work email address.

Once registered, click here to login to the ticket portal.

The portal provides the following functionality:

User account and login to OAL Customer portal.

Visibility and communication history for all tickets within your organisation.

Ability to raise a ticket.

If you need any assistance or have any feedback, ring +44 1733 394701 or email support@oalgroup.com

How to become the global leader in robotic food processing - Roythornes Food Business Breakfast

The UK will be the global market leader for robotic food processing. At the recent Roythornes Food Business Breakfast, Samantha Norman (BEng) shared how OAL is working with academia, our customers and the supply chain to make this vision a reality.

The UK will be the global market leader for robotic food processing. At the recent Roythornes' Food Business Breakfast, Samantha Norman shared how OAL is working with academia, customers and the supply chain to make this vision a reality.

Number 1 in robotic food processing

It sounds good, doesn’t it?

The UK food industry is widely recognised as the global leader in convenience food and innovation but our ability to embrace automation, digital and robotics is critical to ensuring our leadership. It's this leadership that will ensure strong exports and create new jobs in the largest UK manufacturing industry.

We must work together as a supply chain to realise this vision.

Samantha shared how OAL are working with our partners to lead the robotic revolution in ingredient handling and processing. Over 150 delegates from across the supply chain caught a glimpse of this future with a live demonstration of our APRIL Robotics Ingredient Handling System.

Rather than a person handling and weighing out ingredients by hand, APRIL automates the task!

Roythornes Food Business Breakfast

Roythornes Solicitors’ bi-annual business breakfasts invites food and drink industry professionals from a multitude of backgrounds to network; sparking discussion, debate and a collaborative approach to driving improvements in the food and drink industry.

“Our Food Business Breakfast has become a key staple in the networking calendar for business professionals based in both Peterborough and other areas of the UK.

Improved efficiency, reduced labour costs and reliability are all potential benefits to implementing robotics, and Sam offered an interesting perspective on what this actually means in practice, exploring the use of robots in the sector and how the industry needs to work collaboratively in order to stay flexible and compete with organisations within Europe and across the world.”

Join the robotics revolution!

New £900k Robotic Ingredient Handling project

Did you know as much as 5% of a food manufacturer’s turnover is associated with the costs of raw material handling, weighing and preparation? That number is set to drop as engineers, food technologists and computer scientists, drawn from UK industry and academia, collaborate to fully automate the preparation and handling of raw materials.

Did you know as much as 5% of a food manufacturer’s turnover is associated with the costs of raw material handling, weighing and preparation? That number is set to drop as engineers, food technologists and computer scientists drawn from UK industry and academia collaborate to fully automate the preparation and handling of raw materials.

We're leading a major new industrial R&D project in collaboration with researchers from the University of Lincoln, UK, and English Provender Company, an award-winning producer of condiments, dressings and marinades. The collaboration is part-funded by a UK Government grant of almost £900,000 from Innovate UK through its Materials & Manufacturing research fund funding stream.

The project aims to address the unique complexity of food manufacturing ingredient variability. In a given day, food manufacturers can deal with over 200 different raw materials with different states (solid, liquid, frozen, ambient and chilled), packaging format (bag, sack, box and drum), allergens and handling difficulties. It’s this complexity that to date has led to high manning levels, waste and inefficiencies in the industry.

Deploying our suite of APRIL Robotics Material Handling modules as our toolset at the University of Lincoln’s National Centre for Food Manufacturing, the research team is exploring how to integrate robotic and automation solutions at each step of the production process. The research will examine how processes such as product handling and weighing can be streamlined and made more efficient through new robotic technologies.

“The ability to accurately and efficiently prepare, weigh and batch the complex combination of ingredients within our product portfolio really is the engine room of our production environments. The processes involved have a direct effect on food safety, product quality and factory efficiency. We believe that the use of increased automation and technology to provide enhanced control, accuracy and repeatability will have a massive positive effect on all three of these critical factors within this core business function.”

One of the APRIL Robotics technologies that will be used in the project is a micro-ingredient weighing station that uses a collaborative robot to weigh out free flowing and non-free flowing powdered ingredients to an accuracy of 1g. This technology was developed under a separate Innovate UK project between OAL and the University of Lincoln.

“Weighing out powders is a common task across the industry that presents accuracy and health and safety challenges when undertaken by people. By using a collaborative robot and smart algorithms from the University of Lincoln, we can quickly weigh out powders, to a recipe, to an accuracy of 1g with zero cross contamination. In this project, we’re working with EPC to map out their processes and crunch a year’s production data to analyse what the best solution is, looking at the potential for optimisation at each step.”

Robotic micro weighing removes the health & safety challenges associated with manual weighing

Mark Swainson, Deputy Head at the University of Lincoln's National Centre for Food Manufacturing (NCFM) is an expert in the field of industrial food processing technology. He will lead the research team which also includes specialists in robotics, automation and process control from the University of Lincoln’s School of Engineering.

“To unlock improved value, quality and sustainability, the food manufacturing sector needs a game-changing, innovative reinvention of its production processes. We want to push the practical and scientific boundaries of food process technologies, robotic materials’ handling, machine learning, and computer vision systems. The goal is to produce a full technological solution which provides proof that robotics and automation can be the catalyst for much-needed productivity gains in the food manufacturing industry.

The industry needs a step change. All the low hanging fruit has gone. This project is not about marginal gains, it is about identifying a game-changer that can turbocharge productivity in food manufacturing processes.”

If you would like to learn more about ingredient handling and preparation automation, get in touch with our experts today!

OAL to support Deafblind UK in 2018

In 2018, we'll be working with and supporting national sight and hearing loss charity, Deafblind UK to raise awareness and donations for people that suffer from sight and hearing damage.

In 2018, we'll be working with and supporting national sight and hearing loss charity, Deafblind UK to raise awareness and donations for people that suffer from sight and hearing damage.

Deafblind UK support people with sight and hearing loss to live the lives they want and helps to ensure deafblind people have the same rights, access and opportunities as others. They provide a wide range of direct support services and also support and educate external organisations as to how to help their own staff and customers with the challenges being both deaf and blind presents. The charity will be organising an information day at OAL's Peterborough site where they will demonstrate the impact of sight and hearing loss on everyday life to help raise awareness and increase understanding.

Jake pictured in green at the Great North Run 2016

Jake Norman to run the London Marathon for Deafblind UK

Jake Norman, OAL's Head of Sales, will be taking to the streets of London this April to run the London Marathon raising money for Deafblind UK.

“Deafblind UK is a hugely worthwhile charity and we’re excited about the opportunity to support them in any way we can. Even shutting your eyes and ears for just five minutes gives you a sense of the challenges people face. Imagine trying to go shopping, or cook dinner; the world would be a very scary place! So I’m going to push myself to the absolute limits in London for Deafblind UK!”

APRIL™ features in Made Smarter 2017 UK government review

We're very proud to feature in the UK Government Made Smarter Review 2017 launched today! The report sets out the aim for the UK to be a leader in Industrial Digitalisation, and APRIL™ Robotics was highlighted within the food section.

The report discusses the ‘perfect storm’ scenario food manufacturing faces because of an over-reliance on cheap labour:

Restriction on labour supply (due to Brexit).

Rapid above-inflation rises in labour cost (driven by the National Living Wage).

In certain sectors (e.g. fresh produce packing, sandwich manufacturing), up to 90% of the line workforce can be migrant ‘low skilled’ workers.

But for businesses which rise to this challenge, the falling cost and increased functionality of robotics offer quick productivity gains and an ability to exploit new market opportunities and grow exports. Digital technologies are at the heart of being able to exploit this opportunity which is multi-faceted and growing rapidly. Learn more in the video below where our team discuss the role of robotics in reducing capital expenditure.

You can download the full report and read more about the challenges and planned actions to enable digitalisation in food processing.

OAL to build new APRIL™ Robotics production facility

We’re very pleased to announce the development of our new state-of-the-art facility to support our APRIL™ Robotics Systems in Cambridgeshire, UK. The new facility supports a growing order book as food manufacturers seek to avoid rising costs in the UK and Europe through significant productivity improvements.

Currently, 529,800 people globally are associated with the common repetitive task of weighing dry ‘micro’ ingredients. The APRIL Robotics Ingredient Handling system automates this task and when linked with APRIL Logistics, fully automates the ingredient and material management within factories.

The OAL team is rapidly accelerating the adoption of robots in food manufacturing as they focus on increasing productivity and efficiency in food factories by automating manual handling tasks. Harry Norman, Owner/Managing Director at OAL, explains more:

“We’re committed to eliminating manual handling in the front end of food processing, and the new APRIL facility gives our team a great space to develop and demonstrate what that means for food manufacturers.

We have a strong reputation for building large scale material handling projects, and advanced manufacturing software (OAL Connected) and the APRIL developments complement these thriving parts of the business.”

So if you’re ready to bring robots into your facility, arrange a visit to learn more about APRIL Robotics today.

OAL secures £450k funding for robotics in food manufacturing

We’re delighted to announce that we have been awarded £448,850 to develop innovative APRIL™ robotics material handling systems for food manufacturers from Innovate UK, the UK's innovation agency. The new project focuses on overcoming the well-documented productivity challenges food manufacturers face preparing ingredients. It will be led by engineers from OAL utilising the latest robotic and automation technologies.

The new one-year project, which is supported by a grant of £448,850 from the UK Government via Innovate UK and the EPSRC's Robotics and Autonomous Systems (RAS) research fund, will focus on automating the processes of handling, weighing and transporting the raw ingredients. It will also make strides in developing key hygiene and food safety features which will be crucial when using robotic production systems within the food manufacturing sector. Researchers from the University of Lincoln will be supporting the project with work being undertaken at the National Centre for Food Manufacturing, Holbeach, UK.

“Food manufacturers are facing rising costs and with little opportunity to increase their prices, they are seeking new and effective ways of improving productivity. Throughout the project, we’ll be taking a step-by-step approach, working our way through common operations found across the food manufacturing sector such as weighing, sieving, and moving ingredients around.

One criticism of automated systems in the past has been the lack of flexibility, but we will aim to develop flexible APRIL robotic systems that can handle some of these tasks and take the pressure off food manufacturers.”

Take the first step towards the robotic revolution with us - get in touch today.

Ann Savage on the future of chilled food manufacturing

What is the right environment for chilled food innovation? Ann Savage, former Group Technical Director at Bakkavor, spoke at the Food Manufacturing 2030 Conference on the future of chilled food over the next ten years. Discussing the rise of new technologies including robotics, Ann highlighted the pressing need for food manufacturing to create the right conditions for successful innovation. After discussing a number of the wide-ranging challenges food manufacturing faces including environmental and significant cost pressures Ann stressed the importance of creating the right conditions for innovation in the UK. Collaboration between research institutions, technology providers and manufacturers will be very important in realising new developments. Likewise, further investment is needed in skills to realise the benefits of new technologies.

Ann has seen the tremendous growth of the chilled food market which has leapt from revenues of from £5 billion in 2000 to £11.4 billion in 2014 and is still growing. Discussing the benefits and rise of automation and robotics, Ann highlighted amongst others the following areas of interest:

Longer shelf life

Robots can work within controlled environment with limited exposure to bacteria and allergens often carried by people. There are significant opportunities for improving the shelf life of products, reducing waste and improving the overall safety and hygiene of the factory in this way.

Improve decision making

Automation within a factory can also reduce human decision-making. The collection and intelligent use of big data will allow problems to be resolved before they occur, as their played out in digital factories. This will allow factories to plan further ahead, reduce stoppages and save time on resources.

Farm to fork

Improved data collection and analysis will enhance food safety from farm to fork. Big data applications will enable full visibility of the supply chain with in-line quality checks enhancing protection against errors.

If you’d like to bring these benefits into your manufacturing facility, our experts can help you take the first step.

McKinsey report: where will automation replace humans in food manufacturing

Food service and manufacturing sit at the top of a recent McKinsey report that analysed work activities rather than occupations as a predictor of automation. By identifying jobs with predictable physical work, data processing or data collecting, they were able to assess the technical feasibility of automation. By breaking down jobs by activities, up to 59% of time spent at work in the US is highly susceptible to automation. Further analysis suggested that food service and manufacturing were more suited to automation than others i.e. many activities within food manufacturing are highly susceptible to automation.

Technical feasibility of automation in food

The McKinsey report highlights food manufacturing and food service as highly susceptible to automation due to the activities involved in the jobs (see figure 1). The main driver for this is the high amount of time people spend on predictable physical work. Often in food factories, people will undertake a high number of predictable activities such as lifting product, moving ingredients etc. (see figure 2).

In our experience, the trend fits for our customers who manufacture a smaller range of SKUs and have already been able to automate a high number of the predictable activities. This is in contrast to chilled food manufacturing, where upwards of 40 SKUs can be produced per day and predictable and unpredictable activities become intertwined.

One major part of the puzzle will be splitting out the predictable from the unpredictable physical work, thus enabling higher levels of adoption of robotics. For instance, lifting ingredients into a saucepan is a predictable task but judging the taste of the food requires the expertise of a chef, hence it isn't so susceptible to automation.

We're working with the University of Lincoln to develop robotic systems that provide manufacturers the flexibility to split out the predictable from the unpredictable thus enabling greater levels of automation. APRIL™ the Robot Chef installed at the National Centre for Food Manufacturing enables this flexibility by breaking down activities in a different way to traditional manufacturing processes.

Mckinsey Technical feasibility

Mckinsey industry Feasbility