OAL to build new APRIL™ Robotics production facility

We’re very pleased to announce the development of our new state-of-the-art facility to support our APRIL™ Robotics Systems in Cambridgeshire, UK. The new facility supports a growing order book as food manufacturers seek to avoid rising costs in the UK and Europe through significant productivity improvements.

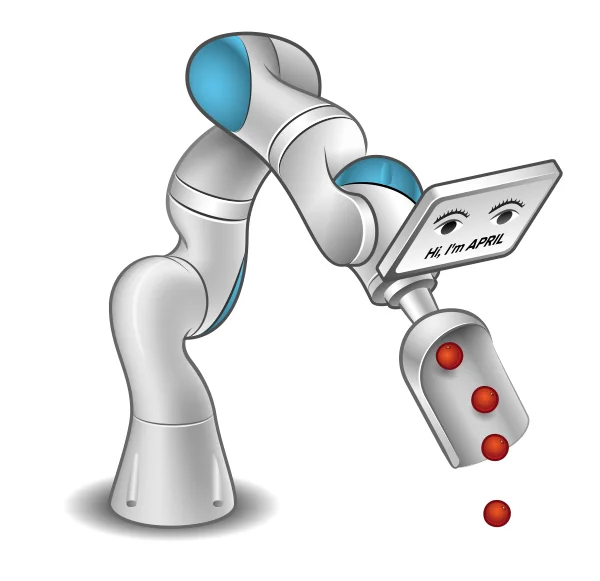

Currently, 529,800 people globally are associated with the common repetitive task of weighing dry ‘micro’ ingredients. The APRIL Robotics Ingredient Handling system automates this task and when linked with APRIL Logistics, fully automates the ingredient and material management within factories.

The OAL team is rapidly accelerating the adoption of robots in food manufacturing as they focus on increasing productivity and efficiency in food factories by automating manual handling tasks. Harry Norman, Owner/Managing Director at OAL, explains more:

“We’re committed to eliminating manual handling in the front end of food processing, and the new APRIL facility gives our team a great space to develop and demonstrate what that means for food manufacturers.

We have a strong reputation for building large scale material handling projects, and advanced manufacturing software (OAL Connected) and the APRIL developments complement these thriving parts of the business.”

So if you’re ready to bring robots into your facility, arrange a visit to learn more about APRIL Robotics today.

OAL secures £450k funding for robotics in food manufacturing

We’re delighted to announce that we have been awarded £448,850 to develop innovative APRIL™ robotics material handling systems for food manufacturers from Innovate UK, the UK's innovation agency. The new project focuses on overcoming the well-documented productivity challenges food manufacturers face preparing ingredients. It will be led by engineers from OAL utilising the latest robotic and automation technologies.

The new one-year project, which is supported by a grant of £448,850 from the UK Government via Innovate UK and the EPSRC's Robotics and Autonomous Systems (RAS) research fund, will focus on automating the processes of handling, weighing and transporting the raw ingredients. It will also make strides in developing key hygiene and food safety features which will be crucial when using robotic production systems within the food manufacturing sector. Researchers from the University of Lincoln will be supporting the project with work being undertaken at the National Centre for Food Manufacturing, Holbeach, UK.

“Food manufacturers are facing rising costs and with little opportunity to increase their prices, they are seeking new and effective ways of improving productivity. Throughout the project, we’ll be taking a step-by-step approach, working our way through common operations found across the food manufacturing sector such as weighing, sieving, and moving ingredients around.

One criticism of automated systems in the past has been the lack of flexibility, but we will aim to develop flexible APRIL robotic systems that can handle some of these tasks and take the pressure off food manufacturers.”

Take the first step towards the robotic revolution with us - get in touch today.

APRIL™ shortlisted for Best Technology Innovation at the World Food Innovation Awards 2017

APRIL pouring water

We’re pleased to announce that our APRIL™ Robot Chef has been shortlisted for the World Food Innovation Awards 2017 in the category ‘Best Technology Innovation’. The esteemed judging panel, including the Global Sustainability Director for Mars, recognised the transformative impact robotics will have on making food manufacturing more consistent and flexible. The winner will be announced on Monday 20th March as part of the International Food and Drink Event (IFE), ExCel London. Click here to see the full list of finalists.

UK food manufacturing faces a number of significant challenges over the coming years, not least the impact Brexit will have on the availability of labour. Sticking with same old, labour-intensive processing and material handling technologies will become cost prohibitive and leave manufacturers unable to fulfil the wide range of products retailers and consumers have come to expect.

APRIL (Automated-Processing-Robotic-Ingredients-Loading) developed with the University of Lincoln, reimagines the food production line, placing robots at the heart of the way we handle and process raw ingredients. By combining advanced materials handling and processing technologies, APRIL can consistently emulate how chefs cook in a professional kitchen bringing more restaurant quality food to our supermarket shelves.

“We are excited by the new thinking involved in the APRIL robotic chef approach. Modular robotics cells may transform food manufacturing kitchens, by breaking up processes in a different way, in doing so providing a step change in performance.”

For manufacturers, smart, robotic food production lines will simplify the way we manufacture products offering flexible consistency. Factories will become up to 80% smaller and the increased levels of control will lead to a safer operating environment and improvements in product shelf-life.

The winner of this award will be announced on Monday 20th March at the International Food and Drink Event at the ExCel in London.

Robotics & Food Manufacturing 4.0. Are you ready?

Whether robots really belong in a food factory is becoming a no-brainer. In order for the food industry to improve and grow, robotics and automation WILL play a major role in the food manufacturing process. Andrea Paoli reveals how robots have taken root so far in our manufacturing systems and are set to revolutionise the food industry in Food Manufacturing 4.0 and beyond.

The value of robotics

Andrea Paoli presented a number of very enlightening figures when introducing the impact robotics will have in the future. Here are a few to set the scene:

The Bank of England in November 2015 predicted that over the next decade, 15 million jobs will be taken over by robots.

In 2020, the robot market is expected to hit a value over $83 thousand million.

It’s predicted that the global saving for using robotics in terms of labour cost is 16%.

By increasing investment in automation by £1.2 billion, this could raise the overall value added by the manufacturing sector to the UK economy by £60.5 billion. This could safeguard 106,000 jobs.

Since the industrial revolution, robots have gone from mechanical production equipment driven by water and steam all the way to cyber-physical systems which integrate computers, networking and physical processes. The degree of complexity of robotics is forever increasing. As you can see from the videos in Andrea's slides, the capabilities of robotics and automation have increased and improved dramatically. Is there anything they won’t be able to do?

So what does Food Manufacturing 4.0 look like?

Robotics and automation have progressed in such a way that it’s safe for them to work in collaboration with humans (HRC systems - Human/Robot Collaborative systems). They can work to full capacity 24/7 producing the same results they’re programmed to complete. This is impossible for humans to achieve to the same degree of accuracy and consistency.

Therefore, there is a massive opportunity for an increase in productivity for food manufacturers due to the reduced cycle and turnaround times. A robot can work within stabilised conditions without human interface. Not only does this improve the health and safety of the factory, it can also increase the shelf life of products contributing to reducing waste which is a very hot topic at the moment!

Working together with the University of Lincoln, OAL has been championing Food Manufacturing 4.0 and have developed a robotic chef APRIL. APRIL is facing up to the challenges food production is facing to introduce a flexible, automated, continuous, high volume system to food manufacturers. Read more about APRIL and her talents here.

How will a future food factory look?

A factory of the future will run on big data being used intelligently to improve decision making and planning. Cloud computing will allow for anything to be controlled, recorded or reported in real-time. With humans collaboratively working together with robots along with all the big data that will be available, factories will be able to optimise production, reduce wastage and improve product consistency and quality.

Join OAL on this journey by helping us educate the industry to deliver disruptive change in manufacturing securing your factory’s future as well as the future of the food manufacturing industry.

McKinsey report: where will automation replace humans in food manufacturing

Food service and manufacturing sit at the top of a recent McKinsey report that analysed work activities rather than occupations as a predictor of automation. By identifying jobs with predictable physical work, data processing or data collecting, they were able to assess the technical feasibility of automation. By breaking down jobs by activities, up to 59% of time spent at work in the US is highly susceptible to automation. Further analysis suggested that food service and manufacturing were more suited to automation than others i.e. many activities within food manufacturing are highly susceptible to automation.

Technical feasibility of automation in food

The McKinsey report highlights food manufacturing and food service as highly susceptible to automation due to the activities involved in the jobs (see figure 1). The main driver for this is the high amount of time people spend on predictable physical work. Often in food factories, people will undertake a high number of predictable activities such as lifting product, moving ingredients etc. (see figure 2).

In our experience, the trend fits for our customers who manufacture a smaller range of SKUs and have already been able to automate a high number of the predictable activities. This is in contrast to chilled food manufacturing, where upwards of 40 SKUs can be produced per day and predictable and unpredictable activities become intertwined.

One major part of the puzzle will be splitting out the predictable from the unpredictable physical work, thus enabling higher levels of adoption of robotics. For instance, lifting ingredients into a saucepan is a predictable task but judging the taste of the food requires the expertise of a chef, hence it isn't so susceptible to automation.

We're working with the University of Lincoln to develop robotic systems that provide manufacturers the flexibility to split out the predictable from the unpredictable thus enabling greater levels of automation. APRIL™ the Robot Chef installed at the National Centre for Food Manufacturing enables this flexibility by breaking down activities in a different way to traditional manufacturing processes.

Mckinsey Technical feasibility

Mckinsey industry Feasbility

Food Manufacturing 2030 Conference - APRIL to cook lunch

Get your lunch cooked by a robot and learn what food manufacturing could look like in 2030. Join us and other food industry leaders to ponder what food processing will look like when we're in driverless cars at the Food Manufacturing 2030 Conference at the National Centre for Food Manufacturing, Holbeach, UK on Thursday 13 October 2016.

See the future

The food industry is ripe for change as it faces a perfect storm driven by the living wage, flat line productivity and food deflation. We believe in order to meet these challenges the industry must transform itself with flexible robotics and automation over the next two decades.

Share in our vision of the future and join us on Thursday 13 October 2016; listen to expert speakers and watch demonstrations as we debate food manufacturing in 2030. Designed for senior food professionals, the event is FREE to attend, and we expect strong discussions as we shape the future of our industry.

APRIL will cook your lunch

Our APRIL robotic food processing platform is pushing barriers and attendees will get a taste of the future as she's cooking lunch. Watch the future of ready meal production as APRIL (Automated Processing Robotic Ingredient Loading) effortlessly twirls a pan around the food processing hall combining ingredients, cooking and cleaning with no human intervention.

Expert speakers

We've brought together thought leaders from across the food industry to provide insights into why and how the food industry will change by 2030. Speakers include:

Simon Lushey, Specialist Technical Manager at Marks & Spencer, will be speaking about why innovation is important to retailing.

Ann Savage, Technical Specialist (Former Group Technical Director at Bakkavor), will be speaking about the future of chilled food manufacturing.

Steve Osborn, Food Technology Scout, will be discussing the consumer trends that will shape food manufacturing moving towards 2030.

Andrea Paoli, Senior Lecturer in industrial automation and robotics at the University of Lincoln, will be speaking about robotic technological developments.

More expert speakers are set to be announced.

Who should attend?

The event is designed for senior food processing and industry professionals looking to learn how robotics and automation will transform their food businesses. Expected delegate job titles include:

Managing Director, Operations Director, Technical Director, Innovation Director, General Manager, Technology/Innovation Manager, NPD Manager, Continuous Improvement Manager

Time to act: robotics in food and beverage manufacturing

APRIL™ Robot Chef

Food manufacturing is facing a perfect storm driven by the living wage; flat line productivity and food deflation. Advanced technology and robotics can address these issues yet the UK is seriously lagging behind the developed world in its implementation. The Office of National Statistics recently announced that the UK has returned to recession for the 3rd time in 8 years. A dive in productivity further underlines the challenge in the UK manufacturing sector. The UK now has a 30% lower GDP per hour than countries such as the US, France and Germany. It must be time for food and drink, the largest manufacturing sector in the UK, to act.

The impact of robotics

In 2014, global robot sales increased by 29% to 229,261 units with the main growth seen in the automotive industry, representing 40% of all robots sold. The UK food and drink sector has a 10-year average adoption rate of just 63 robots a year!

China has expanded its leading position in the adoption of robotics with 25% of the total supply in 2014. High productivity countries such as Germany, France and US show a strong correlation to the number of robotic installations, with the US and Germany featuring in the five countries accounting for 70% of all robot sales along with China, Japan and Korea. France also increased investment in robotics, while the UK’s commitment has been in decline. The forecast for robotic installations sees China looking to around 150,000 by 2018, double the 2014 levels, compared to the UK whose outlook is relatively flat during the same period. The other industrial nations have shown steady growth during the same period.

With the food and beverage sector at such low levels of commitment and as such an important economic contributor, the use of robotics must become part of the vision for the future food factory, and the move to Food Manufacturing 4.0.

Barclay’s bank (2015) forecasts that an investment of £1.2bn in automation will add £60bn to the UK economy, ultimately safeguarding 106,000 jobs. Barclays note that the food and drink sector would be one of the primary sectors to benefit, with productivity improvements of 25% being achieved by 2025. Early indications are proving that embracing automation has enhanced productivity and lead to job creation.

Global centre of excellence for robotic food manufacturing

Working with the University of Lincoln we have been championing Food Manufacturing 4.0 and have developed the transformative APRIL™ Robot Chef. APRIL is challenging the way food production lines are set out, moving away from ‘traditional’ linear continuous production, where high volume and limited flexibility have been the watchwords. APRIL will deliver a system that introduces a return to flexible batch systems, but with intelligent and integrated scheduling that optimises production, improves efficiency and in doing so enhances productivity – Potentially more traditional than continuous linear systems in reality?

At the successful launch of the APRIL Robot Chef in April, we set out our vision to create a Global Centre of Excellence for Robotic Food Manufacturing at the University of Lincoln to:

Educate the industry.

Partner with visionary early adopters.

Deliver disruptive change in manufacturing.

If you’re interested in transforming your facility and bucking the productivity trend, get in touch with our experts!

Successful APRIL™ Robot Chef launch & slides

We launched APRIL™ the Robot Chef at the National Centre for Food Manufacturing during a conference with the University of Lincoln focused on understanding how robotics and automation will change food processing. Food manufacturing is facing a perfect storm driven by the living wage; flat lining productivity and food deflation. Advanced technology and robotics can address these issues yet the UK is seriously lagging behind the developed world in its implementation. Speakers discussed different aspects of this challenge which culminated in live demonstrations of the APRIL™ Robot Chef system in our state-of-the-art test centre.

Food professionals view Steam Infusion & cryogenic cooling

Moving forward, our vision is to create a Global Centre of Excellence for Robotic Food Manufacturing at the University of Lincoln that will:

Educate the industry

Partner with visionary early adopters

Deliver disruptive change in manufacturing.

The APRIL™ system demonstrates the potential of robotics to deliver competitive advantage for food manufacturers and how they can overcome existing challenges e.g. traceability, flexibility, adaptability, quality etc.

Speakers included:

Andrea Paoli, Senior Robotics Lecturer at the University of Lincoln explaining the basics and future of robotics.

Jeff Nowill, CEO, Kuka Robotics UK on the intersector knowledge transfer opportunities for the adoption of robots.

Ian Beauchamp, OAL's Head of Process Engineering on the challenges robotics can overcome on the shop floor.

Mark Swainson, Principal lecturer on the challenges robotics can overcome on the shop floor.

Harry Norman, OAL's Managing Director describing his vision of robotic food manufacturing.

Here are the slides from the day (they can be downloaded by clicking through to Slideshare for Jake Norman’s slides and Jeff Nowill’s slides)

Biographies of speakers:

Andrea Paoli

Andrea has been a Senior Lecturer in Industrial Automation and Robotics since 2014 at the University of Lincoln where he serves as the Programme Leader for the brand new BEng Automation Engineering programme. He is a Senior Member of IEEE and a member of the IEEE Robotics and Automation Society UK organising committee.

Jeff Nowill

Jeff is a chartered engineer; having completed an apprenticeship at Dunlop Aviation, and a degree in Mechanical Engineering at Coventry University. He joined KUKA in 2009, and is CEO of the UK and Irish operations, and sits on the board of ESPRC’s RAS network. KUKA boast a turnover in excess of €3 billion, as a world-class manufacturer of industrial robots and automation solutions.

Ian Beauchamp

Ian’s background is control engineering and business. He draws on over thirty years’ experience working for companies such as P&G and APV within R&D, design, project management together with leading product, service and engineering activities. Ian facilitated Performance Optimisation projects within the food industry in a global position utilising Six Sigma and Lean Methodologies.

Mark Swainson

Mark’s industrial background is Technical and Operations Management within the high risk chilled and frozen food industry. He is listed on the European Food Safety Authority Food Safety Experts Database, is an experienced Lead Auditor and a member of the Institute of Packaging. Mark conducts industry based research to address specific food industry challenges; Quality, Safety and Hygiene Control Systems, Advanced Process Technologies & Automation, Food Supply Chains, Microbiological Safety and Shelf Life

Harry Norman

Harry was just 28, with only a few years of industry experience and a first class degree in controls and automation when he founded OAL (Olympus Automation Ltd) in 1993. OAL now supply cutting edge food manufacturing systems for leading blue chip clients such as Allied Bakeries and Bakkavor that have increased the efficiency and consistency of their manufacturing operations.

OAL secures £60,000 for APRIL™ robot development

We are pleased to announce we have received a £60,000 Agri-Tech Growth Grant for the development of our robotic food processing system, APRIL™. The grant will be used to further develop APRIL™, our fully automated robotic food manufacturing cell that will boost production, efficiency and improve the quality of food produced.

“OAL is transforming the food manufacturing industry through their technology. The APRIL™ system will kick-start the industry’s move towards fully automated production lines, allowing food to be produced quicker, with less waste and greater precision.”

APRIL™ robot with food basket

A full size demonstration system is being built at the National Centre for Food Manufacturing part of the University Lincoln in Holbeach, Lincolnshire - come and learn more about the technology.

OAL discusses APRIL™ at Future Food Horizons

Back in October, OAL travelled to Chester to take part in the Future Food Horizons Conference and introduce APRIL to industry and academic professionals. The conference, led by The University of Chester, was designed to tackle social challenges through food science and innovation. Jake Norman from OAL joined speakers from Innocent, Quorn, Muller and Sainsburys to discuss how they could turn their insights into food and innovation into a solution for social challenges.

Jake's presentation explains how OAL are using insights from the automotive industry to change food manufacturing with the introduction of APRIL™.

Ready to transform your facility? Get in touch with our experts today!

Harry Norman on the launch of APRIL

Harry Norman spoke to Food Bev Magazine back in October, about the introduction of APRIL, robotic food processing. We were invited to speak about innovation at the Next Generation Manufacturing conference at Gulfood Manufacturing in Dubai. Whilst at the show Darren Wood of FoodBev media caught up with OAL's Managing Director, Harry Norman, to discuss our new product.

“We are launching a new product into the market called APRIL which will revolutionise the way the front end processing of food factories is handled.”

Ready to take the next step towards the robotic revolution? Get in touch today!

APRIL™ wins Cambridge Open Innovation Food & FMCG Pitching Event

Our game-changing food processing innovation APRIL™ won over judges from Tesco, General Mills and Mars at the fourth Food & FMCG Innovation Pitching Event. The Cambridge University event took place at Food Matters Live In London, where we pitched APRIL (Automated Processing Robotic Ingredient Loading) to the esteemed group of judges. The judges recognised APRIL's ability to change the way we manufacture food by offering "chef-standard" food whilst significantly reducing production costs.

APRIL is the first of its kind and represents a step change in food processing; enabling parallel food processing and the emulation of a professional chef on an industrial scale.

APRIL will be available for demonstrations in early 2016 at our test centre at the National Centre for Food Manufacturing.

Interview on APRIL™ & Food is Life at PPMA 2015

At the PPMA Show 2015, we were interviewed about our involvement with Food is Life and APRIL™, our food processing robot. APRIL will enable food processing without any platforms or pipework in a smaller factory. Bringing together state-of-the-art technologies, she will increase capacity, significantly reduce the number of operators and produce safer, better looking, tastier foods.

Developed with the University of Lincoln at the National Centre for Food Manufacturing, APRIL enables parallel food processing and can emulate a chef’s method of cooking on an industrial scale. Utilising grant funding from Innovate UK, we have put our expertise and skills into making this research concept a reality with a demonstration available early 2016.

We have been working closely with members of the Food Is Life consortium in the development of APRIL™. Food is Life firmly believes that the food industry can benefit from learning and exploiting technologies from the automotive industry to improve production and safety of food.

Transforming food processing at Gulfood Manufacturing, Dubai

We're speaking about disruptive change at the Next Generation Manufacturing Conference, part of Gulfood Manufacturing 2015 in Dubai on Tuesday 27 October at 15:30. We were approached by organisers following the launch of our revolutionary APRIL™ food processing system. APRIL uses principles from the automotive sector to link proven state-of-the-art cooking and materials handling technologies with automated robotic ingredient loading.

The talk will provide insights into how APRIL™ style systems will change both factory layouts and the flow of materials through a food processing facility. By removing the need for pipework, pumps and valves, APRIL will produce more consistent and better quality products, faster than current processes with significantly reduced ingredient wastage and energy costs, whilst taking up to 80% less factory space.

APRIL™ has been developed in partnership with a leading global robot manufacturer and the University of Lincoln, with a full-size demonstration due for installation December 2015 at the National Centre for Food Manufacturing. The development has come off the back of two £1 million Innovate UK funded government projects into improving the efficiency and quality of food products. APRIL™ will integrate and enhance two existing technologies being researched under the two Innovate UK collaborative research projects into cryogenic cooling and rapid heating and mixing (Steam Infusion).

The three day show is the region's biggest food and beverage processing industry event and brings together suppliers from over 60 countries, showcasing the very latest improvements in manufacturing. The show is a popular knowledge transfer and sourcing event which allows attendees to explore solutions for potential expansion on production capacity, creating greater efficiency and much more!

APRIL™ draws the crowds at the PPMA Show 2015

i8

On the last week of September 2015 industry professionals from all around the world were enamoured by APRIL™ at the PPMA Show in Birmingham, UK. With dual presence at the show, we took the opportunity to introduce our new disruptive technology, APRIL, on the Food Is Life stand. APRIL combines proven state-of-the-art cooking and materials handling technologies with automated robotic ingredient loading, emulating a professional chef.

Food Is Life is a consortium focused on bringing disruptive change to the food industry and accordingly was the perfect setting to introduce APRIL™. The stunning BMW i8 was the perfect back drop for the launch, highlighting the knowledge transfer opportunities available between the food and automotive industry. Visitors sat in the car and were captivated by the video:

It was incredibly effective with many of the biggest names in food production stopping by to discuss their desire for step change improvements in food manufacturing. We are working closely with the University of Lincoln and Food Is Life partners to deliver Food Manufacturing 4.0 and the visitors strong reaction is a great driver to continue the pursuit of change.

Del Boy BMW i8

The three day event saw Del Boy and Joanna Lumley impersonators, an awards ceremony, countless customer meetings and chatter throughout.

OAL would like to say a massive thank you to the organisers of the PPMA and for all our customers, new and returning, for giving us the chance to introduce APRIL™ to the world.