Time to act: robotics in food and beverage manufacturing

APRIL™ Robot Chef

Food manufacturing is facing a perfect storm driven by the living wage; flat line productivity and food deflation. Advanced technology and robotics can address these issues yet the UK is seriously lagging behind the developed world in its implementation. The Office of National Statistics recently announced that the UK has returned to recession for the 3rd time in 8 years. A dive in productivity further underlines the challenge in the UK manufacturing sector. The UK now has a 30% lower GDP per hour than countries such as the US, France and Germany. It must be time for food and drink, the largest manufacturing sector in the UK, to act.

The impact of robotics

In 2014, global robot sales increased by 29% to 229,261 units with the main growth seen in the automotive industry, representing 40% of all robots sold. The UK food and drink sector has a 10-year average adoption rate of just 63 robots a year!

China has expanded its leading position in the adoption of robotics with 25% of the total supply in 2014. High productivity countries such as Germany, France and US show a strong correlation to the number of robotic installations, with the US and Germany featuring in the five countries accounting for 70% of all robot sales along with China, Japan and Korea. France also increased investment in robotics, while the UK’s commitment has been in decline. The forecast for robotic installations sees China looking to around 150,000 by 2018, double the 2014 levels, compared to the UK whose outlook is relatively flat during the same period. The other industrial nations have shown steady growth during the same period.

With the food and beverage sector at such low levels of commitment and as such an important economic contributor, the use of robotics must become part of the vision for the future food factory, and the move to Food Manufacturing 4.0.

Barclay’s bank (2015) forecasts that an investment of £1.2bn in automation will add £60bn to the UK economy, ultimately safeguarding 106,000 jobs. Barclays note that the food and drink sector would be one of the primary sectors to benefit, with productivity improvements of 25% being achieved by 2025. Early indications are proving that embracing automation has enhanced productivity and lead to job creation.

Global centre of excellence for robotic food manufacturing

Working with the University of Lincoln we have been championing Food Manufacturing 4.0 and have developed the transformative APRIL™ Robot Chef. APRIL is challenging the way food production lines are set out, moving away from ‘traditional’ linear continuous production, where high volume and limited flexibility have been the watchwords. APRIL will deliver a system that introduces a return to flexible batch systems, but with intelligent and integrated scheduling that optimises production, improves efficiency and in doing so enhances productivity – Potentially more traditional than continuous linear systems in reality?

At the successful launch of the APRIL Robot Chef in April, we set out our vision to create a Global Centre of Excellence for Robotic Food Manufacturing at the University of Lincoln to:

Educate the industry.

Partner with visionary early adopters.

Deliver disruptive change in manufacturing.

If you’re interested in transforming your facility and bucking the productivity trend, get in touch with our experts!

Successful APRIL™ Robot Chef launch & slides

We launched APRIL™ the Robot Chef at the National Centre for Food Manufacturing during a conference with the University of Lincoln focused on understanding how robotics and automation will change food processing. Food manufacturing is facing a perfect storm driven by the living wage; flat lining productivity and food deflation. Advanced technology and robotics can address these issues yet the UK is seriously lagging behind the developed world in its implementation. Speakers discussed different aspects of this challenge which culminated in live demonstrations of the APRIL™ Robot Chef system in our state-of-the-art test centre.

Food professionals view Steam Infusion & cryogenic cooling

Moving forward, our vision is to create a Global Centre of Excellence for Robotic Food Manufacturing at the University of Lincoln that will:

Educate the industry

Partner with visionary early adopters

Deliver disruptive change in manufacturing.

The APRIL™ system demonstrates the potential of robotics to deliver competitive advantage for food manufacturers and how they can overcome existing challenges e.g. traceability, flexibility, adaptability, quality etc.

Speakers included:

Andrea Paoli, Senior Robotics Lecturer at the University of Lincoln explaining the basics and future of robotics.

Jeff Nowill, CEO, Kuka Robotics UK on the intersector knowledge transfer opportunities for the adoption of robots.

Ian Beauchamp, OAL's Head of Process Engineering on the challenges robotics can overcome on the shop floor.

Mark Swainson, Principal lecturer on the challenges robotics can overcome on the shop floor.

Harry Norman, OAL's Managing Director describing his vision of robotic food manufacturing.

Here are the slides from the day (they can be downloaded by clicking through to Slideshare for Jake Norman’s slides and Jeff Nowill’s slides)

Biographies of speakers:

Andrea Paoli

Andrea has been a Senior Lecturer in Industrial Automation and Robotics since 2014 at the University of Lincoln where he serves as the Programme Leader for the brand new BEng Automation Engineering programme. He is a Senior Member of IEEE and a member of the IEEE Robotics and Automation Society UK organising committee.

Jeff Nowill

Jeff is a chartered engineer; having completed an apprenticeship at Dunlop Aviation, and a degree in Mechanical Engineering at Coventry University. He joined KUKA in 2009, and is CEO of the UK and Irish operations, and sits on the board of ESPRC’s RAS network. KUKA boast a turnover in excess of €3 billion, as a world-class manufacturer of industrial robots and automation solutions.

Ian Beauchamp

Ian’s background is control engineering and business. He draws on over thirty years’ experience working for companies such as P&G and APV within R&D, design, project management together with leading product, service and engineering activities. Ian facilitated Performance Optimisation projects within the food industry in a global position utilising Six Sigma and Lean Methodologies.

Mark Swainson

Mark’s industrial background is Technical and Operations Management within the high risk chilled and frozen food industry. He is listed on the European Food Safety Authority Food Safety Experts Database, is an experienced Lead Auditor and a member of the Institute of Packaging. Mark conducts industry based research to address specific food industry challenges; Quality, Safety and Hygiene Control Systems, Advanced Process Technologies & Automation, Food Supply Chains, Microbiological Safety and Shelf Life

Harry Norman

Harry was just 28, with only a few years of industry experience and a first class degree in controls and automation when he founded OAL (Olympus Automation Ltd) in 1993. OAL now supply cutting edge food manufacturing systems for leading blue chip clients such as Allied Bakeries and Bakkavor that have increased the efficiency and consistency of their manufacturing operations.

OAL partners with Macmillan Cancer Support for 2016 fundraising

not-alone-e1361533920700

macmillan.5

In 2016 OAL will be running, cycling, baking and more to fund raise for Macmillan Cancer Support. As our official 2016 charity, we hope to assist Macmillan (made up of professionals, volunteers and campaigners) in their journey to offer support and inspiration to those affected by cancer, to take back control of their lives.

There are currently 2.5 million people living with cancer in the UK alone with that number expected to reach four million by 2030, so there is no time like the present. It costs £27 for a Macmillan nurse for an hour, that nurse could provide emotional and practical support as well as essential medical advice to those affected by cancer. Nobody should have to go through cancer alone so if you would like to join us in supporting this fantastic charity.

Find out more about our social responsibility!

OAL secures £60,000 for APRIL™ robot development

We are pleased to announce we have received a £60,000 Agri-Tech Growth Grant for the development of our robotic food processing system, APRIL™. The grant will be used to further develop APRIL™, our fully automated robotic food manufacturing cell that will boost production, efficiency and improve the quality of food produced.

“OAL is transforming the food manufacturing industry through their technology. The APRIL™ system will kick-start the industry’s move towards fully automated production lines, allowing food to be produced quicker, with less waste and greater precision.”

APRIL™ robot with food basket

A full size demonstration system is being built at the National Centre for Food Manufacturing part of the University Lincoln in Holbeach, Lincolnshire - come and learn more about the technology.

OAL sponsors Cambridgeshire Kidsafe Scheme

OAL is delighted to announce that we are a proud sponsor of Kidsafe, an organisation that actively commits to helping keep kids safe across the UK and EIRE. Unfortunately, kids’ safety is a major issue these days for everyone involved including parents and teachers. The philosophy at Kidsafe is to make children more aware of the dangers they face without destroying their sense of adventure, they believe the best approach is to make learning about safety fun.

“OAL is pleased to sponsor the Kidsafe School Safety Pack; it’s an important scheme and we like to get involved with and help local charities.”

OAL has sponsored the ‘School Safety Pack’ which is distributed to primary schools around the Cambridgeshire area, in order to educate them on the responsibility of their own safety. This pack includes a ‘Get Home Safely’ game which visually demonstrates the actions to take when faced with issues over their own safety, in a fun board game inspired layout.

OAL discusses APRIL™ at Future Food Horizons

Back in October, OAL travelled to Chester to take part in the Future Food Horizons Conference and introduce APRIL to industry and academic professionals. The conference, led by The University of Chester, was designed to tackle social challenges through food science and innovation. Jake Norman from OAL joined speakers from Innocent, Quorn, Muller and Sainsburys to discuss how they could turn their insights into food and innovation into a solution for social challenges.

Jake's presentation explains how OAL are using insights from the automotive industry to change food manufacturing with the introduction of APRIL™.

Ready to transform your facility? Get in touch with our experts today!

Harry Norman on the launch of APRIL

Harry Norman spoke to Food Bev Magazine back in October, about the introduction of APRIL, robotic food processing. We were invited to speak about innovation at the Next Generation Manufacturing conference at Gulfood Manufacturing in Dubai. Whilst at the show Darren Wood of FoodBev media caught up with OAL's Managing Director, Harry Norman, to discuss our new product.

“We are launching a new product into the market called APRIL which will revolutionise the way the front end processing of food factories is handled.”

Ready to take the next step towards the robotic revolution? Get in touch today!

APRIL™ wins Cambridge Open Innovation Food & FMCG Pitching Event

Our game-changing food processing innovation APRIL™ won over judges from Tesco, General Mills and Mars at the fourth Food & FMCG Innovation Pitching Event. The Cambridge University event took place at Food Matters Live In London, where we pitched APRIL (Automated Processing Robotic Ingredient Loading) to the esteemed group of judges. The judges recognised APRIL's ability to change the way we manufacture food by offering "chef-standard" food whilst significantly reducing production costs.

APRIL is the first of its kind and represents a step change in food processing; enabling parallel food processing and the emulation of a professional chef on an industrial scale.

APRIL will be available for demonstrations in early 2016 at our test centre at the National Centre for Food Manufacturing.

OAL leads research project into cryogenic cooling

We’re pleased to announce the launch of our latest research project set to revolutionise ready meals with cryogenic cooling in partnership with BOC, The University of Lincoln and Iceland Manufacturing. The £969,000 project, part funded by Innovate UK will last two years and aims to develop an innovative cooking and cryogenic cooling system for ready meals providing a step change in product quality and healthiness. The project seeks to help tackle the current levels of food waste and increase the speed of production.

The project will combine our rapid cooking Steam Infusion Vaction™ technology with a cryogenic cooler from BOC. It follows our first major Innovate UK project ‘Nutrition for Life’, that has focused on understanding the full operating envelope of our Steam Infusion cooking technology and it's effects on nutrition and food safety.

Over the two-year project, the team plans to gain a full scientific understanding of the effects of rapid cooling using liquid nitrogen on sauces and soups, and the vegetables, fruits and meats they contain in order to maximise nutritional values. Product shelf life could also be increased and waste minimised as we will develop a fully flexible process that will reduce production, cleaning and changeover times for increasingly variable supply requirements.

Interview on APRIL™ & Food is Life at PPMA 2015

At the PPMA Show 2015, we were interviewed about our involvement with Food is Life and APRIL™, our food processing robot. APRIL will enable food processing without any platforms or pipework in a smaller factory. Bringing together state-of-the-art technologies, she will increase capacity, significantly reduce the number of operators and produce safer, better looking, tastier foods.

Developed with the University of Lincoln at the National Centre for Food Manufacturing, APRIL enables parallel food processing and can emulate a chef’s method of cooking on an industrial scale. Utilising grant funding from Innovate UK, we have put our expertise and skills into making this research concept a reality with a demonstration available early 2016.

We have been working closely with members of the Food Is Life consortium in the development of APRIL™. Food is Life firmly believes that the food industry can benefit from learning and exploiting technologies from the automotive industry to improve production and safety of food.

Join us at Food Matters Live 2015

Join us at Food Matters Live 2015 to find out how OAL is working with The Knowledge Transfer Network (KTN) to bring best practice automotive manufacturing technologies to the food industry. The three day event running Tuesday 17 to Thursday 19 November at the Excel in London is the UK's first cross-sector event bringing together professionals from across the food and drink industry to address the most important challenges facing the food industry today including nutrition and population well-being.

Following two successful Innovate UK projects, OAL has been invited to speak on the KTN stand about both our Steam Infusion and cryogenic cooling projects. We will also be available to talk about our latest development APRIL (Automated Processing Robotic Ingredient Loading) following widespread anticipation for the launch of the new system early 2016. APRIL was recently covered in bakeryandsnacks.com.

Both KTN and OAL are members of Food Is Life, a consortium, which will also be at the event with the stunning BMW i8, seeking to bring disruptive change to the food industry. If you’re interested in joining, it would be great to meet up at the show, you can either catch us on the KTN stand or at the BMW i8 (which will be positioned near the VIP lounge).

The free to attend event attracts thousands of visitors every year from backgrounds such as R&D, food science, manufacturing and retailing so register here to come along and we may even let you take a seat in the car!

Transforming food processing at Gulfood Manufacturing, Dubai

We're speaking about disruptive change at the Next Generation Manufacturing Conference, part of Gulfood Manufacturing 2015 in Dubai on Tuesday 27 October at 15:30. We were approached by organisers following the launch of our revolutionary APRIL™ food processing system. APRIL uses principles from the automotive sector to link proven state-of-the-art cooking and materials handling technologies with automated robotic ingredient loading.

The talk will provide insights into how APRIL™ style systems will change both factory layouts and the flow of materials through a food processing facility. By removing the need for pipework, pumps and valves, APRIL will produce more consistent and better quality products, faster than current processes with significantly reduced ingredient wastage and energy costs, whilst taking up to 80% less factory space.

APRIL™ has been developed in partnership with a leading global robot manufacturer and the University of Lincoln, with a full-size demonstration due for installation December 2015 at the National Centre for Food Manufacturing. The development has come off the back of two £1 million Innovate UK funded government projects into improving the efficiency and quality of food products. APRIL™ will integrate and enhance two existing technologies being researched under the two Innovate UK collaborative research projects into cryogenic cooling and rapid heating and mixing (Steam Infusion).

The three day show is the region's biggest food and beverage processing industry event and brings together suppliers from over 60 countries, showcasing the very latest improvements in manufacturing. The show is a popular knowledge transfer and sourcing event which allows attendees to explore solutions for potential expansion on production capacity, creating greater efficiency and much more!

APRIL™ draws the crowds at the PPMA Show 2015

i8

On the last week of September 2015 industry professionals from all around the world were enamoured by APRIL™ at the PPMA Show in Birmingham, UK. With dual presence at the show, we took the opportunity to introduce our new disruptive technology, APRIL, on the Food Is Life stand. APRIL combines proven state-of-the-art cooking and materials handling technologies with automated robotic ingredient loading, emulating a professional chef.

Food Is Life is a consortium focused on bringing disruptive change to the food industry and accordingly was the perfect setting to introduce APRIL™. The stunning BMW i8 was the perfect back drop for the launch, highlighting the knowledge transfer opportunities available between the food and automotive industry. Visitors sat in the car and were captivated by the video:

It was incredibly effective with many of the biggest names in food production stopping by to discuss their desire for step change improvements in food manufacturing. We are working closely with the University of Lincoln and Food Is Life partners to deliver Food Manufacturing 4.0 and the visitors strong reaction is a great driver to continue the pursuit of change.

Del Boy BMW i8

The three day event saw Del Boy and Joanna Lumley impersonators, an awards ceremony, countless customer meetings and chatter throughout.

OAL would like to say a massive thank you to the organisers of the PPMA and for all our customers, new and returning, for giving us the chance to introduce APRIL™ to the world.

Ready for robots to transform your operations? Get in touch to take the next step!

Disruptive food processing technologies

We recently had the opportunity to discuss how disruptive technologies will deliver a step change in performance for food manufacturing with the Daily Telegraph. With over 25 years’ experience in food processing, we understand the demands of 24/7 operation with tight deadlines and short shelf-life products and are in a unique position to work with the industry. Leading two collaborative research projects with prominent food manufacturers and research institutions, we now invest 8.2% of turnover in R&D.

As Harry says "It's not going to be easy, it's going to be a rollercoaster of change" but the opportunities are huge:

Like the automotive industry, over the next decade, food factories will change dramatically because of disruptive technologies with major implications for the whole supply chain. Food Manufacturing 4.0 has arrived. Highly flexible “lights out” manufacturing will enable the production of new products whilst intelligent product tracking will improve food safety and traceability. Smart factories connected to the industrial internet will react to changing consumers demand at an incredible pace.

That's why we are working as part of the Food Is Life consortium to deliver Food Manufacturing 4.0. The opportunities for embracing disruptive technologies are huge and we are constantly looking for new collaborations and partnerships to work towards this.

Get in touch with our experts to start your transformation today!

OAL dry materials handling featured on BBC!

A recent BBC series, "Inside the Factory: How Our Favourites Foods Are Made" focused on the way bread is manufactured. The programme spotlighted the Allied Bakeries West Bromwich site where OAL Group supplied a turnkey materials handling system for all dry ingredients used in the bread process.

BBCBreadFactory

Clips from the video can be found on the BBC.

Top safety accreditation for OAL

OAL has been awarded accreditation from Safecontractor for its commitment to achieving excellence in health and safety. Safecontractor is a leading third party accreditation scheme which recognises very high standards in health and safety management amongst UK contractors. Safecontractor is applicable to most sectors although it is particularly relevant to food manufacture, property, facilities management, retail and leisure sectors, all of which are big users of contracted services.

“Major organisations simply cannot afford to run the risk of employing contractors who are not able to prove that they have sound health and safety policies in place.

More companies need to understand the importance of adopting good risk management in the way that OAL has done. The firm’s high standard has set an example which hopefully will be followed by other companies within the sector.

Safecontractor plays a vital role in supporting our clients in meeting their compliance needs, whilst working with their contractors as they progress through the accreditation process.”

Under the Safecontractor scheme, businesses undergo a vetting process which examines health and safety procedures and their track record for safe practice. Those companies meeting the high standard are included on a database, which is accessible to registered users only via a website.

Client-organisations who sign up to the scheme can access the database, enabling them to vet potential contractors before they even set foot on site. These clients agree that, as users of the scheme, they will engage only those who have received accreditation.

Over 210 major, nation-wide businesses, from several key sectors, have signed up to use the scheme when selecting contractors for services such as building, cleaning, maintenance, refurbishment or electrical and mechanical work.

Safecontractor is a third party accreditation scheme that assesses health and safety arrangements. Many major clients recognise the scheme and accept the Safecontractor certificate as confirmation of competency.

Ready to work with a Safecontractor accredited supplier? Get in touch today!

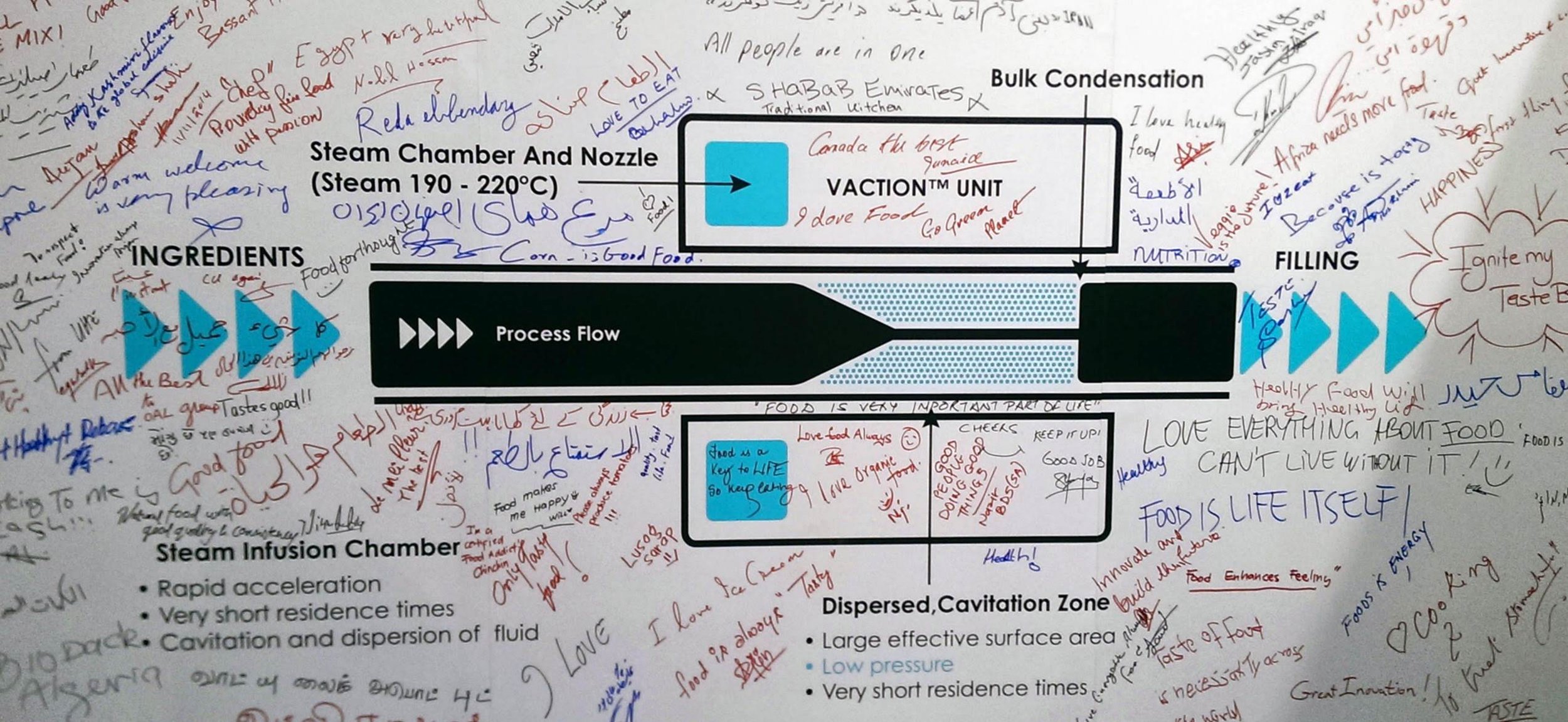

Food is Life at Gulfood Manufacturing "Food Wall"

At Gulfood Manufacturing, Dubai, the biggest food show in Africa and the Middle East, we decided to do something different to engage visitors. Steam Infusion is a revolutionary heating and mixing process, and from previous shows in the UK we recognised we need food manufacturers to think creatively and differently about their manufacturing processes. So to break down barriers and to get people thinking about what’s really important about food, we introduced them to our “food wall”. Visitors were simply asked to write what was most important about food to them on our “food wall”.

We were genuinely amazed by the excitement and engagement with the "food wall". Over the 3 days of the show, 473 people signed the wall from 70 different countries. Writing in Arabic, Chinese, English, Filipino, Hebrew, Japanese, Swahili, and Turkish to name a few. It really was a truly eclectic mix of global opinions on what’s important about food.

What we found?

Coming from the UK we were expecting people to write the commonly accepted important factors of food such as safety, quality, taste and flavour. These were key elements and many people from all over the world cited safety and taste as the most important areas to them.

But interestingly there was a real focus on the fundamental link between food and life. For instance “Food is life itself”, “Can’t live without food”, and “Africa needs more food.”

But should we have been surprised? Nestle, the biggest food manufacturer in the world, has the slogan “Good Food, Good Life,” clearly linking food to life itself and it’s true to say that without food we wouldn’t be here. But on a daily basis as engineers and food manufacturers do we make the connection between food and life in the UK?

But what’s the link with Steam Infusion?

Gulfood Food Wall Steam Infusion Unit

Often at exhibitions visitors have very specific requirements about what they are looking for and to a certain extent are closed down to things outside of their remit. By simply asking visitors to write what’s important about food on the wall, we found visitors opened up much more and were in a much better position to discuss innovation.

This innovation mind-set is really important to us because often with the Steam Infusion process we are radically changing traditional manufacturing processes, for instance going from a multi stage process to a single stage faster process. Likewise we found visitors engaged much more strongly with new product development and step changes to improving flavours and taste having written on the wall.

Hot application at Gulfood

Food is Life Gulfood Manufacturing Steam Infusion

Not only were people able to write on our walls but they could taste the difference as well. On the stand, we had pots of freshly made condensed milk made using Steam Infusion which attracted a lot of interest because of the considerable difference in product quality and operational performance. Steam Infusion condensed milk suffers no burn on discolouration, has a particularly smooth texture and cuts manufacturing times by 50%.

Super Steam Infusion Autumn: 9 innovation events, 6 awards

PPMA Innovation Award Steam Infusion

It’s been a busy September for the OAL team! Off the back of winning an award for Steam Infusion at the European Food Venture Forum in Denmark, we were at Leatherhead Food Innovation Day presenting Steam Infusion followed by the FDF Awards. With lots more events on the horizon, here are the highlights!

Steam Infusion won the most innovative food processing or packaging machine award at the PPMA Group Industry Awards 2014, held at the National Motorcycle Museum, Tuesday 30 September. In a very competitive category, Steam Infusion was recognised as the most innovative technology by the esteemed judging panel because of the health benefits the technology can bring to the food industry.

Steam Infusion EFVF2014AwardWinners

The European Food Venture Forum saw OAL pitching Steam Infusion's ability to create exciting new food products and ingredients to investors and manufacturers. The judging panel included senior executives from Anterra Capital, Arla Foods, BASF Venture Capital GMBH and Dupont Nutrition & Health all of whom assessed the technology on its business potential, technological merit, competitive position, and investment interest and team experience. Strong engagement from the judging panel and an award to go with it was a fantastic endorsement of the technology’s unique processing environment.

Leatherhead’s annual Food Innovation day seeks to showcase exciting technology developments within the food industry. Steam Infusion was well received by executives from 2 Sisters Food Group and Mondelez International particularly around the technologies ability to process heat sensitive food materials.

The very same evening saw the Food & Drinks Federation Awards, where Steam Infusion came runner up in the Innovation category.

Look out for us in the news as we have been shortlisted for more awards:

Ben Bowman

One of our talented engineers, Ben Bowman, is shortlisted for the young talent of the year category at the Food Manufacture Awards.

OAL has been shortlisted for company of the year and technological development at the Food Processing Awards 2014, please vote for us on their website.

Jake Norman, Sales & Marketing Manager, has been shortlisted for the 2 Degrees network Top 25 Under 25 year-olds in sustainability.

With a busy autumn ahead, you can meet the team at the following events:

OAL are sponsoring and will be attending Appetite For Engineering 2014, 21st October. We have a number of complimentary tickets available, please contact us if you are interested in attending, Tuesday 30th September to Thursday 2nd October.

Jake Norman (Sales & Marketing Manager) is speaking at Pack Expo in Chicago on the General Electric stand about Steam Infusion, sharing how we use GE connected insights for R&D into creating new and unique food products and ingredients.

OAL will be presenting at the prestigious Innovate UK Event 2014 “The Global Spotlight on UK Innovation”, 5th & 6th November, Old Billingsgate, London, find out more here.

The team will be at Gulfood Manufacturing, Dubai from 9th to 11th November presenting Steam Infusion, register here.

Winning at the European Food Venture Forum means the team progress to the final of the European Venture Contest in Dusseldorf, Germany, taking place 8-9th December 2014. Find out more here.

Olympus Automation now trading as OAL Group

Effective from Thursday 28th August 2014, Olympus Automation Ltd. will change its trading name to “OAL Group”.

This name change is in response to large international demand for our products and services and better reflects the company’s ability to provide solutions that involve all our engineering capabilities.

While our name is changing, our legal status, office address and telephone contact details will remain the same. The company’s business remains fundamentally unaffected by this change and all contracts with existing customers will remain unaltered, with corresponding obligations and rights assumed under the new trading name.

Moving forward, we look forward to providing the same services that Olympus Automation Ltd. has offered to clients to date and we ask all our stakeholders for their continued support.

From Thursday 28th August, our website will be switching to www.oalgroup.com and email address format to joe.bloggs@oalgroup.com

Steam Infusion shortlisted for FDF Innovation award

Steam Infusion from Olympus Automation (OAL) has been shortlisted for the Food and Drink Federation (FDF) Innovation Award based on its ability to deliver significant and innovative change to the food industry.

Steam Infusion is a revolutionary heating and mixing process that uniquely infuses steam into liquid food products in a vacuum. Early adopters of Steam Infusion include Greencore and Larco Foods who have generated significant business benefits from the technology. explains,

“Steam Infusion has allowed us to nearly double our previous throughput rates in sauce production. On top of this our meat sauce quality and consistency has improved dramatically.”

Further research and development is being undertaken in a £1 million UK government funded Nutrition for Life project at the Steam Infusion Test Centre in the National Centre for Food Manufacturing, Holbeach.

The unique Steam Infusion environment has been found to increase the flavour profile of food products in commercial trials indicating salt and other ingredients can be reduced without having a negative impact on flavour. The Nutrition for Life project seeks to provide the scientific understanding of the level and nature of the changes brought about by the steam infusion process and the nutritional advantage to be gained.

OAL will be presenting initial findings from the Nutrition for Life project at the PPMA show 2014 running from 30th September to 2nd October 2014. As well as the OAL team, academics from the University of Lincoln will be on the stand to answer questions on Steam Infusion and the project.