OAL featured on ITV News Anglia

OAL appeared on the local news on 20 November 2020, discussing the benefits that a new university in Peterborough will bring to our business and the region.

OAL appeared on the local news on 20 November 2020, discussing the benefits that a new university in Peterborough will bring to our business and the region and demonstrating our robotic weighing system!

On Friday 20 November 2020, Harry Norman was featured in a news report from ITV News Anglia focusing on the new Anglia Ruskin University ARU Peterborough campus. Harry shared his views on the great new pipeline of talent that the university will bring to the city and hopefully to our business as we continue to grow and offer our innovations to manufacturers around the world. You can also take a peek at our APRIL Robotics Ingredient Handling system in operation in the video!

ARU Peterborough will provide a practical solution to the problem of low employment and skill levels across Peterborough, helping to increase employability and skills and retain talent in the region while also bringing additional opportunity and prosperity to the area. The university has been created to address a higher education ‘cold spot’ which has been identified, as well as widening participation by attracting a diverse student population from non-traditional backgrounds to improve social mobility and to redress the skills gaps within businesses and industries across Peterborough and the rest of the region.

The new university in Peterborough is set to open its doors to 2,000 students in 2022 with plans to offer courses for up to 12,500 students by 2030. Working with employers like us to develop and deliver the curriculum, which will be led by student and employer demand, the University will offer courses in engineering and technology skills. Courses will be delivered through a mixture of on campus lessons, in-work training, and apprenticeships, with distance learning and outreach programmes to improve accessibility and attract more talent. We’re looking forward to working with the University and students to offer further opportunities in our thriving city!

If you’re interested in our technology or want to hear more about opportunities with OAL, contact us today!

OAL takes part in Social Mobility Pledge

OAL has recently taken part in a new social mobility report with our partner, the University of Lincoln, and led by Rt Hon Justine Greening MP, who pioneered the Social Mobility Pledge. Discover the findings and read the report, including OAL’s role and our case study.

OAL has recently contributed to a new social mobility report produced by our partner, the University of Lincoln, and led by Rt Hon Justine Greening MP, who pioneered the Social Mobility Pledge.

Justine Greening with the University of Lincoln report

The new report outlines the impact of the partnership between the University of Lincoln, food industry employers and local schools in the Holbeach area in supporting social mobility and describes how this ecosystem of opportunity has helped to transform the options open to local children over the past decade.

The Social Mobility Pledge was set up by Justine Greening, then Secretary of State for Education, in 2018 to work alongside businesses and universities to tackle regional disparities and ensure there are opportunities for all. As Greening states in her foreword to the report, the University of Lincoln “has truly stepped into that wider role of a ‘levelling up university’, addressing issues that are relevant to its region’s problems and, through its own investment and effort, creating opportunities that link in with the expertise of the local area.”

The University of Lincoln sponsors the Lincolnshire Educational Trust, an academy trust of local primary, secondary and special educational needs schools based in Holbeach and surrounding villages in South Holland, as well as running a major education, training, and industrial R&D facility in Holbeach – the National Centre for Food Manufacturing (NCFM). The centre serves the skills and innovation needs of the UK's £110bn food and drinks sector, connecting local schools with a global industry and creating a new pipeline of talent for the sector. This is where OAL’s apprentices study and where we house our Steam Infusion & APRIL Robotics test centre.

OAL is a University of Lincoln project partner, offering a path into the workplace from the University and achieving great results for both the individuals and our company, as can be seen in our case study in the report. Samantha Norman, Director at OAL, took part in a round table discussion with Justine Greening, members of the University of Lincoln and other employer partners at the virtual launch event on 3 November 2020.

“We were delighted to take part in this report tackling such an important issue. It’s great to see the success of apprenticeships and how they can help people to overcome the ‘opportunity deficit’, both in terms of learning at the University and the support and development on offer as part of the team at OAL. We look forward to working with the University of Lincoln to support more young people in the future. ”

We’re committed to supporting the next generation getting into the world of work and developing the skills they need to thrive, whatever their background. The University has worked with the community and employers like OAL to raise aspirations and attainment, enhance educational opportunities, support businesses and create pathways for local people into highly-skilled employment and we’re very proud to partner with them.

OAL digitises its operations

In mid-2020, as the UK remained in lockdown due to COVID-19, we were awarded a grant to digitise our operations. As a result of the steps taken, we’re now working smarter, working faster and being more productive, helping the business to accelerate significantly.

In mid-2020, as the UK remained in lockdown due to COVID-19, we were awarded a grant to digitise our operations. As a result of the steps taken, we’re now working smarter, faster and more productively, helping the business to accelerate significantly. James Palmer, Mayor of Cambridgeshire & Peterborough, visited us to see how we got on!

Banishing paper to the recycling

Harry and the team were able to digitise the business thanks to the COVID-19 Capital Grants Scheme from the Cambridgeshire & Peterborough Combined Authority. With a grant of around £48,000, OAL was able to make the most of the quieter period at the height of the lockdown to take steps to streamline operations and take advantage of new technologies. This meant an end to old systems generating what amounted to around 14 square metres of paperwork and non-integrated software which made it difficult for our teams to work collaboratively.

“This grant has been extraordinarily important for the future of our business. People are now doing in two hours what it might have take them all day to do before. We’re estimating productivity gains of about 20% within our business.”

State-of-the-art pods

The digitisation comes with 14 new, fully-equipped pods for staff to work in. Building work for the new pods and the setting up of the new equipment has been very cost-effective, using local contractors, prefabricated panels, Amazon Alexa hubs and Microsoft Teams software, for example, to slash the cost of a typical refit and overhaul. This meant we actually achieved double the number of pods than what was originally envisioned with the grant money.

Each pod is self-sufficient with its own ventilation, lights and screens allowing one person to work in a quiet, productive environment, where they can collaborate with colleagues and customers easily through video calls and shared documents, allowing for a more interactive way of working.

The pods also allow people to work in two-metre spaces, adhering to the latest public health guidelines, as beforehand the original open plan office environment provided too many distractions and meetings were not always productive.

“Adversity does create opportunity and COVID-19 has given us time to reflect. We had too much paperwork and our systems held back our potential to work more effectively as a team. The more we have rolled out this technology, the more we wished we had done it sooner.”

We received a ringing endorsement from Mayor Palmer, who was amazed by how much we achieved with the grant and commented that we had created “the most innovative, paperless 21st century office” and “the future of offices”. The Cambridgeshire & Peterborough Combined Authority were exceptionally helpful throughout the application process, offering practical information and even making themselves available at weekends to help support us at what was a difficult time across the world. The transformation that we made wouldn’t have been possible without the grant so a big thank you to Mayor Palmer and the rest of the Cambridgeshire & Peterborough Combined Authority team!

Ready to work with the new and improved OAL? Get in touch with us today!

Harry Norman's top 4 tips to thrive in 2020

With almost 30 years working with the food industry, Harry Norman’s seen it all and knows how to help manufacturers to extend machinery life or carry out refurbishments to meet revised process requirements and boost productivity. Here are his top four tips for thriving during these straitened times.

During the current climate of uncertainty, it’s clear that food manufacturers are up against it. Having to meet increased demand with fewer people while also implementing social distancing measures to protect staff and at the same time working with equipment that has perhaps seen better days… It’s certainly been a hard few months and it’s likely to continue. As reported in The Times, analysts at Peel Hunt have calculated that £23 billion has been cut from CAPEX budgets for this year in British listed companies alone. This means that it could be some time before manufacturers can consider investing in new machinery, let alone innovations to take operations to the next level.

It’s now more important than ever to make the most of what you have, something that our MD, Harry Norman, knows plenty about. With almost 30 years working with the food industry, he’s seen it all and knows how to help manufacturers to extend machinery life or carry out refurbishments to meet revised process requirements and boost productivity. Here are his top four tips for thriving during these straitened times.

Digital transformation

Productivity has always been the key buzzword in the global economy, but it has perhaps never been more necessary to return to pre-2008 levels. It was reported in February 2020 that the slowdown in productivity growth in the UK over the last ten years is the worst since the start of the Industrial Revolution 250 years ago, and the impact of COVID-19 is likely to have only worsened this situation.

So the question is, how can you increase your productivity, particularly if you can’t invest in major capital equipment? One way is to begin your journey towards digital transformation. By digitising your operations, you can typically achieve productivity savings of 10% running smarter and leaner and making the most of your existing assets. For example, by going paperless, your plant data can be transformed into useful insights, rather than disparate sheets of paper, allowing you to identify bottlenecks, downtime issues and waste. Our experts, trained in Six Sigma, alongside our software such as our LMS or APRIL Eye, can help you drive productivity gains across your entire facility.

Process simplification

Total production time for three 1,000 kg (2204 lb) batches of béchamel sauce using a traditional steam jacketed kettle vs. Steam Infusion.

When was the last time you reviewed your processes? We mean really delved into the detail? Chances are, it’s been a while and you could benefit from a fresh set of eyes highlighting any simplifications or rationalisations that can be made to speed up operations and boost efficiency. OAL is 100% dedicated to the food industry, and having completed hundreds of projects for manufacturers, both big and small, it means our experts can look at things differently, saving our customers millions of pounds through simple changes to improve throughput.

For example, one of the ways in which we can reduce the processing time of a béchamel sauce is by using our award-winning Steam Infusion technology, which not only achieves faster cooking times but also reduces the number of processing stages required. The traditional roux is not needed at the beginning of the process, and Steam Infusion can be used to mix whilst heating, while the lack of burn-on means that the number of CIP cycles can be reduced by up to 80%, saving valuable time and money.

Focus on maintenance

There’s no doubt that as people, we’re all more interested in innovation than maintenance, and it’s no different when it comes to plant equipment. But while budgets are tightened, it will become vital to make the most of your existing kit. It might be tempting to reduce maintenance right now but while you may see short-term gains, you could see long-term damage. An effective maintenance schedule and working with experts can help to take care of your kit to help it last longer.

For example, our Steam Infusion technology can also be used to extend vessel life. There’s no need to condemn your kettle cooking system and invest in a new jacket or tank if it fails the pressure tests or is no longer cooking efficiently. A simple retrofit adding one of our In-Tank Steam Infusion Vaction Pumps breathes new life into your existing kit, while delivering added benefits such as near maintenance-free operation and energy efficiency – particularly valuable at this time.

Consider used equipment

As we see the unfortunate news that some plants are closing due to the challenging economic conditions, we will inevitably see a rise in used kit coming on to the market, and this will be of a better quality that can usually be found. This can often be a cost-effective way to boost your productivity but it can be a challenge to find the right equipment and ensure that it is installed seamlessly into your existing processes.

While used kit can often represent a bargain, it requires a diverse set of engineering resources to integrate equipment that doesn’t meet your exact requirements. It may look great on paper but there are a number of questions to consider, such as how old is it, what is the warranty, are the controls current and even how will you get it to your plant?

Working with trusted partners, such as OAL, who have experience in delivering both new and refurbished equipment, as well as effective maintenance, ensures you get the right advice before committing, allowing you to minimise the risk and maximise savings.

Get in touch today to see how we can support you during this time!

SafeContractor accredited for the fifth year in a row

We’re thrilled to announce that we’ve been approved as a SafeContractor for the fifth year in a row. Receiving this accreditation recognises our dedication to health and safety, both in terms of our workforce and how we work to protect our employees and our customers. When you work with OAL, you can be sure you’re in safe hands partnering with a responsible company.

We’re thrilled to announce that we’ve been approved as a SafeContractor for the fifth year in a row. Receiving this accreditation recognises our dedication to health and safety, both in terms of our workforce and how we work to protect our employees and our customers. When you work with OAL, you can be sure you’re in safe hands partnering with a responsible company.

What is SafeContractor?

Alcumus SafeContractor is a leading third-party health and safety assessment scheme initiated by the UK government under Safety Schemes in Procurement (SSiP). SSiP promotes a minimum standard of health and safety assessments and helps customers to identify which companies meet the UK’s rigorous health and safety requirements. The accreditation is a sign of professional and credible contractor business, and all listed businesses can be found by registered customers via the client web portal. For any customers who are not clients, further information can be found on the SafeContractor website.

How do you become SafeContractor approved?

To gain accreditation requires that we provide examples of all our health and safety paperwork to ensure it is up to date and meets legal industry requirements. This includes risk assessments, method statements, COSHH assessments and working at height, to name just a few!

SafeContractor is applicable to most sectors although it is particularly relevant to food manufacture, due to the number of contracted services. The SafeContractor seal of approval means you can be sure that we’re doing all we can to adhere to the very highest standard of health and safety and legal compliance, providing you with peace of mind when our teams carry out work on your sites.

With our accreditation, you can be sure you’re getting the very best service from us. Got a project in the food industry? Get in touch today!

OAL celebrates double win at MiCE awards 2020!

We’re delighted to announce that we have won two awards at the MiCE awards! We took home the Manufacturing Innovation Award for our APRIL™ Robotics Ingredient Handling System, and we were also presented with the Manufacturing Apprentice/Training Scheme Award. Now on to the finals in June 2020 - fingers crossed!

We’re delighted to announce that we have won two awards at the Made in Central & East (MiCE) awards! We took home the Manufacturing Innovation Award for our APRIL™ Robotics Ingredient Handling System, and we were also presented with the Manufacturing Apprentice/Training Scheme Award. We were up against some tough competition so we’re thrilled to have been recognised by the judges and are extremely proud of the hard work of our teams. Following on from the regional awards we’ve been entered into the national finals in Liverpool – hopefully we can repeat our success in June 2020!

Innovative APRIL

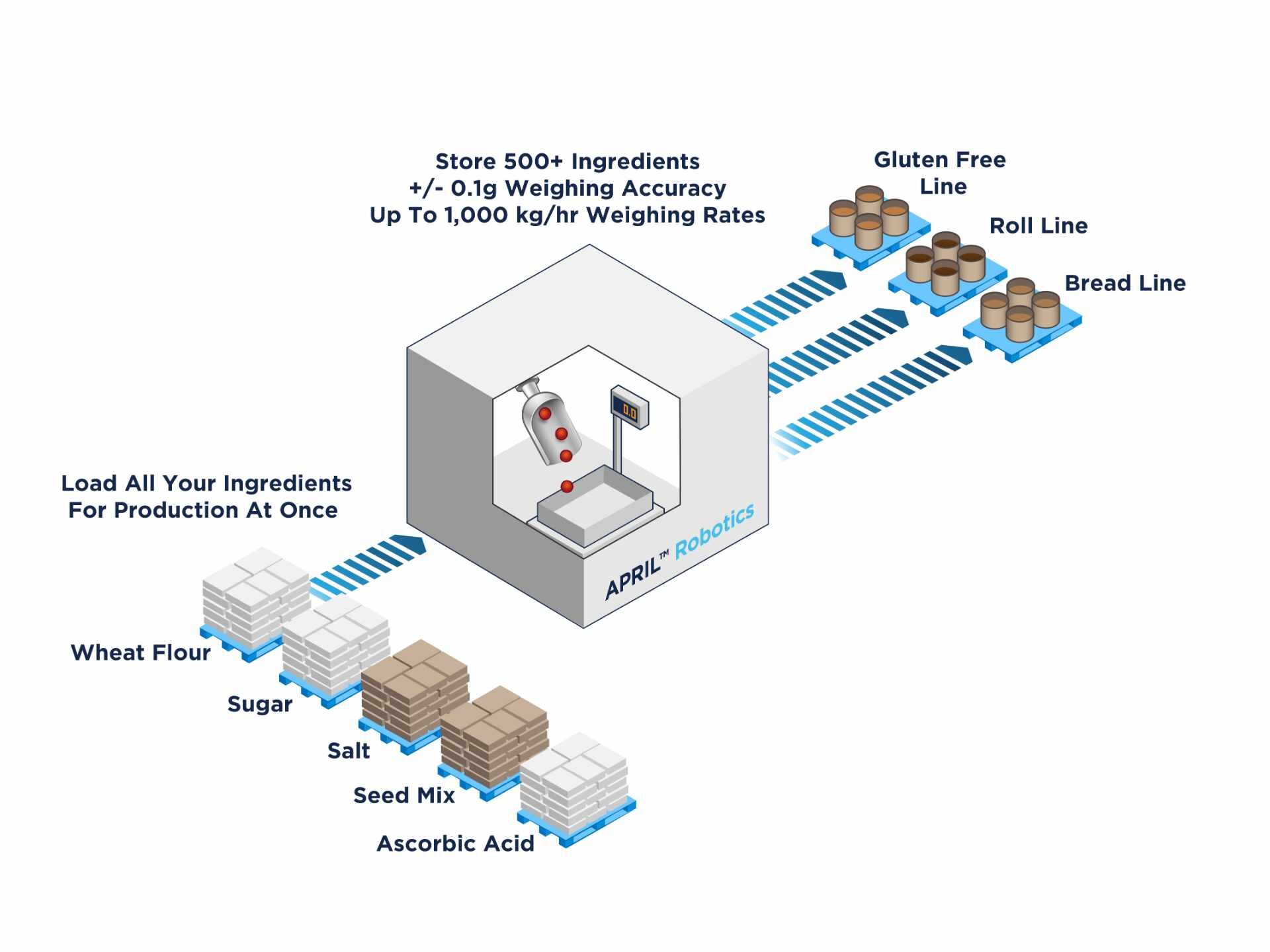

Our APRIL Robotics Ingredient Handling system revolutionises the way that ingredients and components are handled in industrial facilities. The judging panel was impressed with our innovative design and our goal to improve operations in facilities across the globe. Weighing and scaling of powders is a key task in nearly all manufacturing operations everywhere but it can prove costly to manufacturers, primarily due to labour costs. Manual handling in harsh and dusty environments can also have an extremely detrimental impact on employees’ health but there hasn’t been a viable alternative before now.

The APRIL Robotics Ingredient Weighing system offers a real alternative to operators on the factory floor. Not only does the system’s cells automatically weigh powders to an accuracy up to +/- 1g at weigh-up rates of up to 1,000kg/hr, but it also offers full traceability and can help to reduce waste. What’s more, with wages on the rise, the APRIL Robotics Ingredient Handling System can help to reduce labour costs by allowing you to implement unmanned operations in your facility.

Dedicated to development

We also took home the Manufacturing Apprenticeship/Training Scheme Award! We’re dedicated to supporting training and development, and at any one time we have an average of 15% of our workforce completing further studies or an apprenticeship. The judges highlighted our commitment to investing in training to ensure that the right people are in place to drive the business forward and offer solutions to meet the challenges of tomorrow in the food industry. Our partnership with the University of Lincoln, among other education providers, allows us to invest in our people so our employees benefit from recognised qualifications. We’re extremely proud of the hard work and commitment put in by our staff and are truly honoured to have been awarded the accolade by the judges.

Find out more about our award-winning solutions!

OAL FoodTech Open Day global success

Thursday 30 January 2020 saw us hold our first FoodTech Open Day to demonstrate our innovative technology and the impact it can have on the food and beverage industry. The sold-out event welcomed attendees from around the globe, and with live demonstrations and expert presentations, we certainly got our attendees thinking!

Thursday 30 January 2020 saw us hold our first FoodTech Open Day to demonstrate the latest in food technology and how it can transform the food and beverage industry. The sold-out event welcomed attendees from around the globe to our test centre at the National Centre for Food Manufacturing (part of the University of Lincoln) and offered an exclusive behind the scenes look at the latest in food tech. With live demonstrations and expert presentations, we certainly got our attendees thinking!

Take a look at the highlights from our latest event!

Unmanned flexible food manufacturing

The day began with a presentation detailing the vision of unmanned flexible food manufacturing with APRIL Robotics. Harry Norman, Managing Director of OAL, explained the development of our automated solutions designed to tackle today’s challenges including productivity, labour costs and consumer demand. Attendees were also introduced to Steam Infusion, the key to unlocking high speed processing to keep up with the production rate of these new robotic systems.

Perhaps the highlight of the day was witnessing Steam Infusion in action on our Robot Chef as it effortlessly created a sweet fruit sauce within minutes. Not only was the robot a real sight to behold, capturing the attention of all our visitors, but the sauce was extremely well received in the taste test!

Breakout sessions

The afternoon consisted of attendees being split into rotations for a more in-depth look at different challenges within the food industry that new technology can help to overcome. Andrea Paoli, Associate Professor in Food Robotics and Process Automation at the NCFM, demonstrated the University of Lincoln’s latest project; using cobots to replicate human operators in weighing out micro ingredients, while Jake Norman, Head of Sales, and Ian Beauchamp, Process Engineering Manager, offered a guide to food manufacturers looking to take the first step towards digital transformation.

Sustainability was the subject of the afternoon presentation led by Dr Wayne Martindale, who brought over 20 years’ experience to the captivated room. The attendees then got to experience a savoury cook with Steam Infusion led by Development Chef Chris Brooks that got the taste buds tingling. And finally, our visitors got to hear about the latest automation developments with OAL Connected, including LMS and the world’s first artificial intelligence-based solution for label and date code verification, APRIL™ Eye.

It truly was a varied day and we’re very grateful to all those attendees who came and participated so enthusiastically - we enjoyed every minute!

If you missed the event and want to hear more, get in touch and we can arrange a meeting with our experts.

OAL celebrates further education with the University of Lincoln graduation 2020

January welcomed graduands to Lincoln Cathedral to celebrate the achievements of the students of University of Lincoln for their winter graduation ceremony. We were even able to watch our very own Development Chef Chris Brooks don his gown and mortarboard and celebrate his success in completing his foundation degree!

Graduation is one of the most important days in an academic’s life, and 22-23 January 2020 welcomed graduands to Lincoln Cathedral to celebrate the achievements of the students of University of Lincoln and its satellite campus, the National Centre for Food Manufacturing (NCFM) for their 2020 winter graduation ceremony. We have been the proud partners of the University of Lincoln for many years, and were honoured to have been a part of the day with sponsorship of a prestigious prize. We were even able to watch our very own Development Chef Chris Brooks don his gown and mortarboard and celebrate his success in completing his foundation degree - congratulations Chris!

Chris putting his knowledge into practice at our Steam Infusion Test Centre

Supporting staff

Chris has over 35 years experience in the food industry, and has recently returned to education to complete his foundation degree in Food Science and Technology. Not only has he furthered his own personal and professional development, but Chris has also been a key figure in mentoring and assisting students in their studies. Chris’s degree is invaluable to understanding the reactions food undertakes in cooking and in explaining the science behind our Steam Infusion technology to prospective customers. We are really proud of the hard work Chris has put into his studies, and are looking forward to supporting him as he works towards his full Bachelors degree in Food Science and Technology!

Prize presentation

Sam Norman, HR Director at OAL, presenting Steve Kettle, Bakkavor, with his certificate

As well as supporting our staff, we were also honoured to sponsor the Award in Recognition for exemplar work-based project on a Foundation Degree in Food Operations and Supply Chain Management. This was awarded to Steve Kettle at Bakkavor, and was presented by Sam Norman, our HR Director. It was a great opportunity to be able to celebrate the hard work of so many individuals in the food and beverage industry. We thoroughly enjoy being the partners of the University of Lincoln and NCFM, and share their dedication to further development and flexible study.

Dedicated to development

Here at OAL we are passionate about professional and personal development, and often encourage our employees to undertake qualifications or training. Our dedication to continuous development even saw us awarded the SME Apprentice Employer of the Year at the Peterborough Telegraph Apprenticeship Awards in 2019, and we could not be prouder of the hardworking individuals that make up our teams.

Do you want to help shake up how our food is made? We are always on the lookout for new talent, so why not take a look at our careers page?

2019 charities at OAL

At OAL we are passionate about supporting good causes, both locally and further afield. We’re always coming up with new ideas of ways to raise funds and awareness for our chosen charities, as well as continuing our ongoing partnership with Kidsafe. Here we round up the charities we supported in 2019.

At OAL we are passionate about supporting good causes, both locally and further afield. We’re always coming up with new ideas of ways to raise funds and awareness for our chosen charities, which are usually put forward by our team members. Not only this, but we also have an ongoing partnership with Kidsafe, a nationwide organisation which works towards creating a world in which children are aware of the dangers they face.

Here we round up the charities we supported in 2019.

Q1 – Peterborough Soup Kitchen

In February 2019, we held a Valentine’s day bake sale and raffle to raise funds for the Peterborough Soup Kitchen. The charity’s principal aim is to ensure that homeless and disadvantaged people in Peterborough receive hot food and drinks throughout the year. Between 35 and 60 people are served each day, making the soup kitchen a vital part of the local community, and we were proud to have been able to support this worthwhile cause for our first quarter.

Q2 – Addenbrookes Neuro Critical Care Unit (NCCU)

To coincide with the Grand National in April, we held a sweepstake across the business to raise money for the NCCU. Approximately 1,100 patients are treated each year on the NCCU, of which a large proportion have neurological or neuro surgically related illnesses. The NCCU works tirelessly to provide intensive care that can ultimately minimise disability and maximise potential for recovery. Our sweepstake meant we could raise funds to support the critical care unit, while engaging in some light competition across the business!

Q3 – British Lung Foundation: Breathe Easy Group

July saw us hold a diversity lunch with a dual purpose. We wanted to celebrate the diversity of our team through everyone’s favourite medium: food, while simultaneously raising money for the British Lung Foundation: Breathe Easy group in Peterborough. This valuable group offers support and research into lung conditions to ultimately prevent, treat and cure lung diseases. Amongst our cuisine we saw a cheese and pineapple hedgehog, Polish croquettes, beef rendang and un gâteau au chocolat – what a feast from our multicultural team!

Q4 – Peterborough Food Bank

Our final nominated charity was the Peterborough Food Bank. We coincided our fundraising with the Great British Bake Off final and had our very own OAL Bake Off to raise much-needed funds, as well as organising a food bank collection across the business. We were able to donate over three boxes worth (80kg!) of food to the Peterborough Food Bank in time for Christmas. With the need for emergency parcels growing by 23% versus the same period in 2018, we’re committed to doing all we can to help families in Peterborough who are struggling.

If you want to be part of our fundraising activities, get in touch today!

Harry Norman's predictions for 2020

As we gear up for another busy year and the start of a new decade, Harry Norman, our founder, reveals his top trends for 2020.

As we look to the start of a new decade, we’re taking some time to speak with our founder, Harry Norman, to discuss what he thinks are the key trends in 2020.

Harry, what are your top trends for 2020?

I think main focus in the food industry in 2020 is a continued focus on improving productivity. This will be achieved through a variety of initiatives as well as the growth in adoption of tools like robotics and machine learning.

It seems like productivity is a permanent concern for food & beverage manufacturers. How can they make a material difference to their productivity levels in 2020?

Productivity has been a major concern for businesses around the world for over a decade but we don’t seem to be able to find the right answer. Latest figures from the ONS showed that productivity in the UK fell at its fastest annual pace in five years in during the April-to-June quarter of 2019, so arguably the problem is getting worse rather than better. Productivity in the food industry has been dropping due to increased product complexity, which requires more production staff to achieve the same volume. This has also led to further erosion of margin as labour costs continue to increase. In April 2019 the national living wage for those aged 25 and over in the UK increased by 4.9%, from £7.83 to £8.21, and it’s set to rise further. The same trend can be seen across the globe so manufacturers need to think outside the box in terms of their productivity.

We know that this is a real priority for our customers but we find that the solution is often in overlooked areas of manufacturers’ operations and that small savings can really add up. For example, if you’re carrying out offline printing on your packaging line, the time taken for a changeover for a new supplier code can quickly mount up. We’ve been able to save customers typically 1-2% of line manning hours by automating the changeover, allowing them to increase production time and reduce labour costs as fewer personnel are needed on the line. By working with experts to review their operations, food manufacturers can find many examples like this and boost their productivity levels by increasing efficiencies.

Robots are another way for manufacturers to boost their productivity – do you think adoption in the food industry will grow in 2020?

Absolutely! As an industry we have generally been slower to adopt robotics than others such as automotive. But the barriers are starting to be broken down and we’ve already seen growth of 50% in robot adoption over the past five years, primarily due to retailer pressure for larger volumes at lower prices combined with consumer demand for safer and more sustainable production. However, we know that this growth has primarily been driven by robotics on the packaging line. I believe that 2020 will be the year that we achieve significant growth in robotics upstream in the processing stage of food and beverage production.

In 2018, we began to see reference sites piloting our robotics technology, and now as we enter 2020 this technology is really taking off. Food and beverage manufacturers are eager to take advantage of the proven results that APRIL Robotics can bring. Our robot chef and automated ingredient handling system allow manufacturers to move to unmanned production, boosting productivity, cutting labour costs and improving product safety – three priorities for manufacturers all over the world. We’re able to achieve payback within two years on our systems so automation of your processing stages needn’t be a pipe dream!

Closely related to robotics is the trend of machine learning. What do you think the impact of this technology will be on the industry?

Machine learning has the potential to transform the food industry. Many companies in Asia have already adopted AI in their food safety processes and it can be used in all areas of the food industry to aid continuous improvement & process optimisation, forecasting, the speed and accuracy of operations, and of course, productivity. A 2017 study by PWC found that global GDP will be 14% higher by 2030 as a result of AI adoption, which will contribute an additional $15.7 trillion to the global economy.

I believe AI will play an even bigger role in 2020. However, it can be really difficult for food manufacturers to know where to start. At OAL we help manufacturers to incorporate AI into their packaging lines to boost productivity by scanning over 1000 packs per minute inline much more accurately than human operators every could. Our AI-based label & verification systems also allow manufacturers to keep up with changing packaging formats without the need to re-programme the system – saving time and increasing throughputs. And because you have machine vision with a brain, you can switch to unmanned operations, further supporting your bottom line by reducing labour costs, all the while preventing product recalls and reducing waste. It’s a great first step for manufacturers looking to take advantage of the benefits of AI.

Are you ready to tackle your productivity challenge in 2020? Get in touch today to see where we can boost your production.

Spotlight on a career as Automation Development and Support Team Leader

Ethan Stone, 26, is an Automation Development and Support Team Leader at OAL. He lives in Alconbury with his fiancée.

Day in the life of…

Ethan Stone

Ethan Stone is an Automation Development and Support Team Leader at OAL. He lives in Alconbury.

My alarm goes off…

At 7.30am. I’m not a breakfast person so I generally get up and head straight for the shower to wake myself up. I then get dressed and try to wait for my partner to return from her night shift before I head off or sometimes I head straight into work.

I’m responsible for…

The day to day running of my department, which consists of myself and four other engineers. I lead the Factory Systems Automation team, and we are mainly responsible for the line management system (LMS), which is a production line automation solution providing performance monitoring to help increase efficiency within factories. I report to my manager with frequent updates on how we are doing to ensure we deliver the best for our customers. As the primary contact for the department both internally and externally I spend a lot of time speaking with current and prospective clients.

I got the job…

Based upon my previous experience working within automation in the oil and gas industry. I showed that I had a real passion for problem solving, which is ideal for OAL. I flourish in a setting that gives me autonomy to come up with practical solutions to hard technical problems – something I get to put into practice every day!

My typical day…

Could be anything! It could range from interpreting customer requirements and building a proposal for them or I could be working on any of the stages during our project lifecycle, from specification or development to testing and commissioning. Or I could be out and about supporting our customers with one of our existing systems. No two days are the same!

My most memorable moment…

Was graduating from my HNC in Electrical and Electronic Engineering. This was four years of education in parallel to working full time, including being on-call out of hours. It was hard work but it certainly paid off! I never saw myself wearing the gown and walking in a procession to celebrate my education in a cathedral but I’m so glad I did it.

The worst part of my job is…

That there sometimes aren’t enough hours in the day! It can feel like for every item I tick off my to do list, two more get added!

The best part of my job is…

Interacting with experienced engineers across a range of disciplines. From process engineers to plant operators – it’s a two-way conversation. Also, seeing something you’ve developed in action in real life; it’s really rewarding.

After work…

I drive home and cook dinner together with my fiancée. We then chill out and have some well-deserved rest and catch up with each other – I love finding out how her shift at the hospital was and what interesting patients she’s encountered.

Would you like to get involved in developing market-leading automation solutions? We are always on the look out for talented individuals, so get in touch to find our more!

Spotlight on a career as Installation Electrician

Will Woodham, 22, is an Installation Electrician at OAL. He lives in a small village outside Spalding.

Day in the life of…

Will Woodham

Will Woodham is an Installation Electrician at OAL. He lives in a small village outside Spalding.

My alarm goes off…

Usually in the early hours of the morning! The exact time depends on which site I’m working on, it could be anywhere in the U.K. and sometimes in Europe!

I’m responsible for…

Installing electrical systems for all of our solutions at our customers’ sites alongside my colleagues.

I got the job…

Originally through an apprenticeship scheme in 2014. My sister works for one of our customers, so she and gave me a list of companies that I might be interested in. Fortunately, OAL came back to me and the rest is history!

I originally worked as an apprentice electrician while studying at Peterborough Regional College to achieve my Level 3 NVQ Diploma in installing electrotechnical systems and equipment. Having finished my apprenticeship in 2018, I was promoted to become a fully qualified electrician, with greater responsibilities.

My typical day…

Can vary a lot, from working inside a factory, bakery or construction site to getting on top of silos and installing electrical systems and equipment. It keeps it interesting!

My most memorable moment…

Is always witnessing our systems go from drawings on a computer screen to fully functioning systems producing the food we buy in the supermarket.

The worst part of my job is…

The temperatures: the general rule is we’ll be working in hot bakeries in the middle of summer and working outside in the middle of winter!

The best part of my job is…

Being able to travel around the country and abroad!

After work…

When we’re away on site, we all usually go out together in the evening to a restaurant and have dinner, go back to the hotel, relax and watch TV.

Like the sound of what Will gets up to? As the winner of the SME Apprentice Employer of the Year 2019 in Peterborough, we’re always looking for apprentices to join the team!

OAL marks four years of support for Kidsafe

Since 2015, OAL has supported the charity, Kidsafe, a nationwide organisation which works towards creating a world in which children are aware of the dangers they face whilst maintaining their sense of adventure.

Since 2015, OAL has supported the charity, Kidsafe, a nationwide organisation which works towards creating a world in which children are aware of the dangers they face whilst maintaining their sense of adventure. The charity aims to make learning fun, tackling important topics such as stranger danger, racism and bullying, and the green cross code in an entertaining format, including the games packs that OAL supports.

Kidsafe provides safety books, leaflets, posters, and games free of charge to almost every primary school in the country, and we’re delighted to be able to contribute to such a great cause. The safety packs that they offer are professionally designed to capture the imagination of children, helping them to learn these essential safety skills more effectively.

Kidsafe school safety pack

“OAL in Peterborough has helped Kidsafe distribute thousands of games packs to school children across Cambridgeshire over a number of years to great success, helping many under 12s lead safer lives and avoid a trip to A&E. Thanks to the support of Samantha Norman and her team, we are going to be able to provide games packs to many more children, including those with special needs in particular, and we hope to be able to report similar successes with these children in the future”

OAL is dedicated to supporting the next generation as part of our corporate social responsibility programme. From work experience placements to school visits, we’re actively involved in encouraging young people as they progress into the world of work and these educational packs are a great way for us to further develop children’s skills to give them the best start possible.

If you’d like to see more of what we do here at OAL, why not sign up to our newsletter? Just fill out the form below.

OAL supports further education in the food industry

OAL sponsored the award for Best Overall Performance on an Apprenticeship at the University of Lincoln’s graduation prize-giving event for the academic year 18/19.

Wednesday 11th September 2019 saw The University of Lincoln’s National Centre for Food Manufacturing (NCFM) graduation prize-giving event for the academic year 18/19. This year marked the first year a cohort of students received their full technical degree through an apprenticeship route.

Harry Norman, OAL, presenting Sheryl with her award for ‘Best Overall Performance on an Apprenticeship’.

For the second year running OAL sponsored the award for Best Overall Performance on an Apprenticeship. The award was won by Bakkavor’s Product Development Apprentice, Sheryl Gamble, and was presented by OAL Managing Director, Harry Norman.

Sheryl graduated this year having completed her Level 6 Food Industry Technical Professional degree apprenticeship. The judges selected her for the prize due to her confidence, her ability to learn and her role as a great employer ambassador. Whilst working with Bakkavor, Sheryl has made a significant impact on the NPD department and has played a key role in boosting the wider collaboration with departments and customers.

The NCFM leads the way in part-time study for food industry employees and we have a close relationship, where a number of our team are currently studying there. They’ve also been a partner in developing our latest innovations, including our robot chef and our state-of-the-art Steam Infusion test centre.

Sam Norman, OAL, speaking at the ceremony.

“It’s an exciting time to work in the food industry with the developments in robotics and automation. Apprenticeships are a hugely valuable way to attract and develop the people who are the future of the industry. The degree apprenticeship route is a great partnership between an employee with the motivation to learn, a business willing to provide opportunities and an excellent learning provider like the University of Lincoln”

At OAL, around 12% of our employees are currently studying across multiple disciplines, from engineering and food science to marketing and finance. Our continuous dedication to education and supporting our employees earned us the title of SME Apprentice Employer of the Year at the Peterborough Telegraph Apprenticeship Awards 2019 and we employee award-winning apprentices; personal and professional development is at the heart of the company.

If you want to become a part of our exciting journey as we shake up the food industry, take a look at our current vacancies! We’re always on the hunt for new talent to expand and grow our business.

Spotlight on a career as Assistant Management Accountant

Louise Gore is Assistant Management Accountant working within the Finance office. She lives in Huntingdon with her partner Neil and her son Owen.

Day in the life of…

Louise Gore

Louise Gore is Assistant Management Accountant working within the Finance office. She lives in Huntingdon with her partner Neil and her son Owen.

My alarm goes off…

At 6.30am and snoozed several times over! I then have a mad dash around the house to get ready and after several moans at my teenage son to get going, we’re both in the car and off by 8am.

I’m responsible for…

Many things finance related but over the past 6 months I have mainly been focusing on the looking after the company’s accounts to aid managerial planning and commercial decision-making, working closely with our Financial Controller.

I got the job…

Because I was in the right place, right time I believe. I had just been made redundant and saw the job advertised. I knew I was a good fit for the role, particularly with my existing qualifications so I was really pleased when I was offered the job!

My typical day…

Starts with going through any emails that have come through after I have left (I work part time). My work can change from day to day; I can be working with sales orders and chasing up timesheets to putting financial reports together for the management team to analyse departmental and overall performance.

My most memorable moment…

Can’t be pinned down to just one as I have had many in the finance office: contrary to popular belief finance is the place to be if you want to have good 'work-related' fun!

The worst part of my job is…

Filing…does anybody actually like it?!

The best part of my job is…

Working with such a knowledgeable team across the whole of OAL. Although I’m based in the finance office, I get to touch base with other departments throughout the week and see all the interesting things they are up to. It’s also great that we have so many training opportunities at OAL; I have started an apprenticeship to become ACCA qualified, which is really exciting!

After work…

If I’m not taxiing my son around to various places I like to relax with a good meal (generally made by Neil!) and maybe a glass of wine. The dog occasionally gets a walk too!

Looking for your next opportunity? We are always looking to grow the team with talented and ambitious individuals, so why not explore our careers to see what’s available!

Kyle Constable wins Apprentice of the Year at FDF Awards 2019

We are thrilled to announce that our Technical Sales Lead for Steam Infusion, Kyle Constable, has been named as the Apprentice of the Year at the Food and Drink Federation (FDF) awards 2019!

We are thrilled to announce that our Technical Sales Lead for Steam Infusion, Kyle Constable, has been named as the Apprentice of the Year at the Food and Drink Federation (FDF) awards 2019! Largely seen as the industry benchmark for innovation, competitiveness and talent, the awards ceremony saw Kyle fight off tough competition to be presented with the Apprentice of the Year accolade. With over 500 guests coming together to celebrate the achievements in the industry, this award is a true testament to the hard work put in by Kyle over the course of his apprenticeship so far.

Pioneers as potential industry leaders

The FDF Apprentice of the Year is awarded to the individual who has shown exceptional progress in both their skills and studies and are real pioneers with potential to become industry leaders. Kyle has been a degree apprentice with OAL for two years now, having originally joined as a Process Development Trainee. He excelled in his position and after only 10 months was promoted to Technical Sales Lead. He is currently completing a degree in Food and Drink Manufacturing Operations Management at the University of Lincoln, all while promoting our innovative Steam Infusion technology across the UK and Europe.

But it isn’t just his own personal development that is so important to Kyle. He uses all his experience to show students that there are many different ways to be successful after leaving school and takes every opportunity to encourage them to consider a career in engineering. We are really pleased for Kyle and it is great to see that all his hard work has been recognised and has truly paid off.

Want to be part of something special?

We are very proud of our employees and are always looking for new people to join our team and support our growth at OAL. If you think you might be interested in an apprenticeship like Kyle, why not visit our apprenticeships page, or get in touch today to find out more about what we can offer.

SME Apprentice Employer of the Year at the Peterborough Apprenticeship Awards 2019

We are honoured to announce that we have won the SME Apprentice Employer of the Year at the Peterborough Telegraph Apprenticeship Awards 2019!

We are honoured to announce that we have won the SME Apprentice Employer of the Year at the Peterborough Telegraph Apprenticeship Awards 2019! The awards aim to celebrate leading apprenticeship schemes in the local area – from the apprentices themselves, to the training providers and employees that support them. We are delighted to have received the accolade as we were up against some tough competitors from a variety of industries. It’s very rewarding to see that our dedication to education and supporting our employees has been recognised by the judges.

Passionate about employees

Here at OAL we are passionate about encouraging our employees in both their personal and professional development, and often support them to complete apprenticeships and degrees while working. Currently in our company of around 65 employees, 12% are studying across multiple disciplines. We feel that this approach – working and earning a salary whilst completing valuable qualifications and developing industry knowledge – benefits both our employees and the company as learnings can be put into practice from day one.

Great facilities to aid apprenticeships

Our partnership with the University of Lincoln, who were recently named number 17 in The Guardian’s University league tables for 2020, and their satellite campus at the National Centre for Food Manufacturing (NCFM) in Holbeach, means that our apprentices have access to modern and innovative facilities, with the opportunity to get hands-on with experiments and trials. The NCFM, which is seen as a national exemplar for its apprenticeship provision, is home to our revolutionary Steam Infusion test centre where apprentices can get involved in the experiments and understand how the system works by experiencing one-to-one training.

Not only do our apprentices get access to the facilities of leading institutions in the UK, they also receive dedicated training from industry experts. Our passion for growth and development means we ensure apprentices get the best of both worlds, with access to great facilities with committed teachers, whilst being part of an exciting, welcoming and innovative team.

Want to know more?

Would you like to be part of an award-winning team that encourages personal and professional opportunities? We pride ourselves on our commitment to supporting the development of our teams and are always on the lookout for talented individuals to join us. Why not take a look at our latest vacancies to see if you could begin your career at OAL!

OAL boosts manufacturer productivity at PPMA 2019

OAL is sponsoring the Networking Zone for a second year running at the PPMA Total Show 2019. We’ll also be showcasing our innovative robotics and automation solutions, as well as our patented cooking technology over the course of the three days.

Stand A130 - Networking Zone, PPMA, NEC Birmingham, United Kingdom, 1-3 October 2019

OAL is sponsoring the Networking Zone for a second year running at the PPMA Total Show 2019. We’ll also be showcasing our innovative robotics and automation solutions, as well as our patented cooking technology over the course of the three days. Visiting the stand, you’ll be able to experience how the APRIL Eye artificial intelligence-based label and date code verification solution replicates human vision and learn from our experts about how our solutions can improve your productivity.

We’re delighted to announce that we’ve also been shortlisted for an award in the Outstanding Customer Service category for the excellent work that our support team puts in with our OAL Connected customers - fingers crossed we win!

Eyeing up productivity improvements

As the UK continues to deal with a productivity crisis, we are demonstrating how our solutions can support you in delivering increased outputs. APRIL Eye, the world’s first artificial intelligence-based vision system for label and date code verification, will be in action on the stand, so you can see for yourself how the technology prevents the wrong date codes from entering the supply chain while maximising throughput. Running at speeds of over 1,000 packs a minute, the system ensures full protection of your production line without compromising on volumes.

APRIL Eye combines machine learning and artificial intelligence to transform the traditional date code verification process. Rather than relying on operators to check the date code is printed correctly, APRIL Eye automates the process using basic cameras backed up with an artificial brain. This vision system can deal with variations such as lighting, positioning, print quality and placement, which are inherent in a food or beverage plant and read anything that is also legible to the naked eye. In this way, APRIL Eye eliminates errors, offers full traceability and protects consumers and brands while at the same time reducing labour costs and waste. The system also improves over time, further safeguarding your operations.

Steaming ahead

Our experts will be on hand to explain how Steam Infusion’s patented technology can double production capacity and halve CIP time in the production of soups, sauces and dairy desserts to maximise productivity. Steam Infusion is an advanced food processing technology that can heat 1,000kg of product from 15°C to 90°C in under 10 minutes with no burn-on or particulate damage. A unique form of steam injection, the patented design of the Steam Infusion Vaction™ pump uses steam as the motive force to heat, mix and pump liquids with and without particulates. High operating costs are prevented thanks to lower energy usage based on Steam Infusion’s highly efficient energy transfer as well as reduced maintenance and removal of condensate management, allowing you to further boost your bottom line.

Weighing up the benefits

If you visit our stand, you’ll also be able to try your hand at manually weighing powders accurately. Manual handling and weighing of ingredients can cost up to one per cent of your turnover. However, by automating ingredient handling and storage with the APRIL Robotics Ingredient Handling system, you can reduce labour costs while eliminating cross-contamination and maximising traceability and accuracy to improve productivity.

Combining robotics and advanced automation, the APRIL Robotics Ingredient Handling system offers a flexible and scalable solution that delivers an accurate and cost-effective alternative to operators on the factory floor. The system automatically weighs powders to an accuracy up to +/- 1g at weigh-up rates of up to 1,000kg/hr. It can also deal with a wide weighing range without any mechanical change components, reducing the risk of downtime caused by machine stoppages or breakdown. The cells have a turndown of 1,000 to 1 while maintaining the highest level of accuracy and zero product cross-contamination risk - increasing traceability and improving food safety. Offering high flexibility, the system can be easily integrated into your existing footprint.

If you missed us there but want to learn more about our systems, contact our team today!

Spotlight on a career as Project Coordinator

Sharon Proctor is a Project Coordinator working in the OAL Connected team at OAL. She lives in Peterborough with her husband Richard.

Day in the life of…

Sharon Proctor

Sharon Proctor, is an Project Coordinator working in the OAL Connected team at OAL. She lives in Peterborough with her husband Richard.

My alarm goes off…

At 6.30. We get up straight away as we have three cats who won’t let us sleep a moment longer when food is on the cards! I have breakfast with my husband and then get dressed and ready for work. Before leaving, I make us a packed lunch and then we hit the road for the short journey into work.

I’m responsible for…

Coordinating the administration for the OAL Connected team and their projects to ensure the smooth running of the whole department – I keep the team and our customers happy!

I got the job…

Originally around ten years ago. I started out as OAL’s receptionist and administration assistant, then progressing to office coordinator, a role I had for several years. Around two years ago I took on my current position in the OAL Connected team, having expressed an interest in moving into this department. When I moved to OAL Connected, I was amazed by how much I learned even though I had already been in the company for eight years!

My typical day…

Always starts by checking in with the team to make sure that everyone knows what each one of us is up to for the day; the guys are usually travelling all over the place visiting customers or carrying out support, so it’s a good way to start the day. I also double check that all arrangements have been made for those who are travelling so that no one is left stranded anywhere!

Then I start to work through ongoing projects, making sure that every aspect is accounted for to ensure accurate costs are logged and checking stock levels so that costs are controlled and we always have the right inventory for our customers.

My most memorable moment…

And the one that has had the most lasting impact on me is the fact that I met my now husband while working here! We met on my first day, had our first date a year later and then got married two years ago! (And we still work and live together very happily!)

The worst part of my job is…

Can be that we’re a team which is often subject to last minute changes! It keeps me on my toes at least!

The best part of my job is…

Getting to work with so many different people every day. The nature of the role means I need to work with every member of the OAL Connected team so it keeps my day interesting!

After work…

I like to go walking with my husband and we can usually be found hitting the pavements wherever we need to go (distance permitting!) We have also recently discovered our love of cruising as it’s a great way to explore many cities in one holiday so we always like to be planning our next adventure! And of course, we spend a lot of time pampering our three truly spoiled cats!

Interested in a career at OAL? We have a range of roles available and are always looking for talented individuals to join the team!

Work experience in summer 2019

In support of World Youth Skills Day (a UN initiative) on 15 July 2019, we thought we’d hear from two school students who have spent time with us and how OAL helps to inspire the next generation into the world of engineering.

At OAL, you can usually find a school or university student somewhere around the business experiencing what it’s like to work for an SME engineering company. Whether it’s school visits to the NCFM to see our equipment in action or work experience students getting a taste for the working world, we love welcoming the next generation into our business and demonstrating the different areas of engineering that are on offer.

The facts

The UN has highlighted that 16 per cent of the global population is made up of young people aged 15 to 24 years and that they’re almost three times more likely to be unemployed than adults so it’s vital that employers help them into the world of work. What’s more, Engineering UK predicted an annual shortfall of 59,000 engineering graduates and technicians for core engineering roles in the UK over the next ten years, so we take our responsibility to encourage more students into the world of engineering very seriously! In support of World Youth Skills Day (a UN initiative) on 15 July 2019, we thought we’d hear from two school students who have spent time with us.

Why did we choose OAL?

Hadi Mohammadi: “I am currently studying maths, chemistry and history at A level, which means there are a wide variety of careers that I can pursue. Engineering is an industry that’s always in demand so there are lots of opportunities for anyone interested in STEM-based careers. I came to OAL for my work experience as the larger companies seemed to be less personal in their approach to tackling work experience placements. As I will be soon be applying for university, working with different departments at OAL has given me a wide range of knowledge including which branch of engineering I want to follow!”

Eve Osborne: “Originally, I had considered engineering as a career as I am currently studying for my GCSEs and am particularly interested in maths and science. However, I also enjoy art and being creative, which I have discovered can be important in certain types of engineering. I wanted to come to OAL for my work experience because of my interest in engineering but had not yet decided which branch would be best for me. OAL was great because the team allowed me to spend time with all the different departments within the company. This not only gave me an insight into what every day jobs of engineers are like but also about all the different departments that are necessary to run a successful business.”

What did we do?

“Throughout our time at OAL, we got to experience many different aspects of the business. We were able to spend some time at the NCFM (National Centre for Food Manufacturing) to see the Steam Infusion system demonstration and the APRIL Robot Chef in action, which was an amazing experience. In addition to this we spent some time with the APRIL Robotics team where we were able to control the robot to complete certain engaging tasks.

In the workshop we were shown how to wire panels and even spent some time wiring them ourselves. The design team showed us how they used CAD (Computer Aided Design) and allowed us to try to complete some technical drawings as well as showing us the simulations that they programmed. This gave us many new and important skills which will be helpful in our futures as engineers.

Over parts of our week with OAL we spent some time with the administration team where we were able to complete helpful tasks and shown how important every aspect of the company is.”

Would we recommend it?

“Overall, we found work experience at OAL to be extremely beneficial in every aspect as all the staff were willing to give their time and answer all our questions enthusiastically. As students, we found our time with OAL was not only really helpful in deciding our futures but also a motivating and exciting experience and would definitely recommend work experience at OAL to other students interested in any aspect of engineering.”